Ultrafine Spherical Tungsten Powder Preparation by RF Plasma Spheroidization

- Details

- Category: Tungsten Information

- Published on Friday, 29 March 2019 23:06

At present, the preparation of spherical tungsten powder at home and abroad mainly adopts radio frequency plasma spheroidization method. The spherical tungsten powder prepared by this method has high sphericity. However, due to the agglomeration of tungsten powder, the spherical tungsten powder grows up after spheroidization, and it is difficult to produce spherical tungsten powder with particle size less than 10 micrometers. Therefore, how to obtain spherical tungsten powder with uniform particle size distribution has been paid more and more attention by scientists and technicians.

Tungsten Carbide Carbon Composites Preparation by Microemulsion Method

- Details

- Category: Tungsten Information

- Published on Friday, 29 March 2019 23:00

Tungsten carbide has a catalytic activity similar to platinum. It has stable physical and chemical properties and low cost. With people's attention to clean energy, the application of tungsten carbide in catalytic fields, such as direct methanol fuel cell, catalytic hydrogen evolution, supercapacitor and catalytic desulfurization, has attracted extensive attention of scientists.

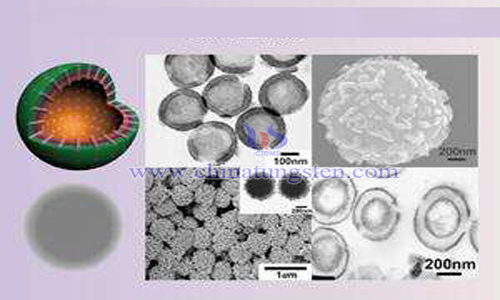

Tungsten Trioxide - Titanium Dioxide Core Shell Structure Nanocomposites Preparation

- Details

- Category: Tungsten Information

- Published on Friday, 29 March 2019 22:53

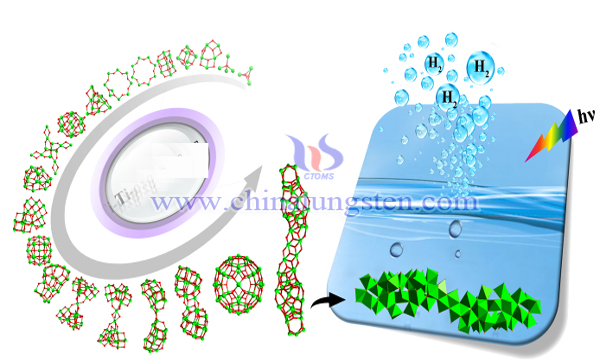

Tungsten trioxide has a narrow band gap (2.6-2.7 eV). The band structure of tungsten trioxide can match well with that of titanium dioxide. By compounding it with titanium dioxide, a composite with core shell structure can be obtained, which has better photoelectric or photocatalytic properties than that of a single component (titanium dioxide or tungsten trioxide).

Ultrafine Tungsten Copper Powder Preparation by Hydrothermal Synthesis

- Details

- Category: Tungsten Information

- Published on Thursday, 28 March 2019 23:19

Tungsten copper alloys are widely used in resistance welding, electrical contact materials and EDM plasma electrode materials due to their high strength, high hardness, arc erosion resistance and fusion resistance. It can be used in the lead frame of large scale integrated circuits, heat sink substrates of solid-state microwave tubes and the throat lining of rocket nozzle with short-term high temperature resistance in aerospace technology.

Monolayer Tungsten Disulfide Helps Evolution of Lithium Iron Phosphate Batteries

- Details

- Category: Tungsten Information

- Published on Thursday, 28 March 2019 23:10

With the boom of new energy vehicles, more and more researchers are devoting themselves to the research of new energy batteries with high performance. At present, lithium-ion batteries have become the most basic battery materials because of their high energy density, long service life and no pollution to the environment. However, cathode materials are becoming the main bottleneck in the industrialization of lithium-ion batteries.

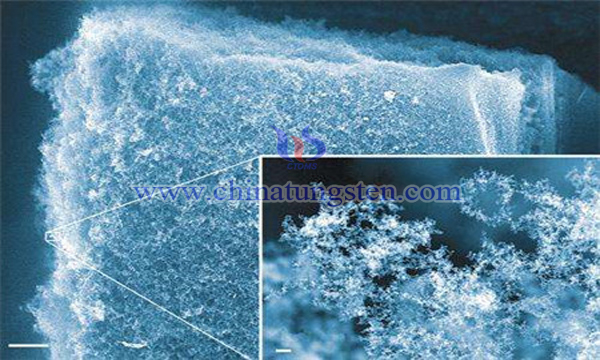

Tungsten Carbide-Carbon Nanofibers Composite Film as a New Electrode Material

- Details

- Category: Tungsten Information

- Published on Thursday, 28 March 2019 22:47

Tungsten carbide is a typical transition metal carbide, which belongs to hexagonal system. Tungsten carbide has good conductivity, and nano-sized tungsten carbide has good potential to replace noble metals as catalysts for hydrogen evolution. Therefore, it has attracted wide attention in the field of catalytic hydrogen evolution.

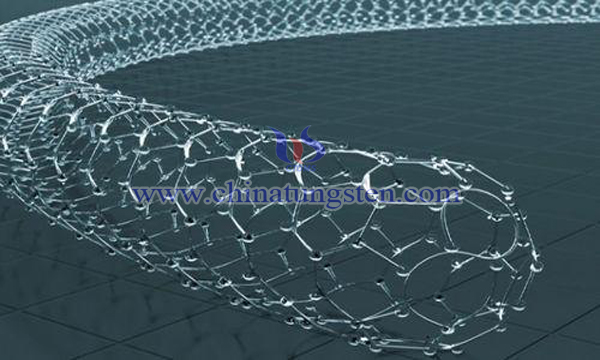

Carbon Nanotubes and Tungsten Carbide Composites

- Details

- Category: Tungsten Information

- Published on Thursday, 28 March 2019 22:41

In recent years, the research on mechanical properties of high performance composite cemented carbides has become one of the frontier topics in the field of cemented carbides. Carbon nanotubes are one-dimensional nanomaterials composed of stable C_C covalent bonds, which have super comprehensive mechanical properties.

Visible Light Photocatalytic Materials of Zinc Tungstate - Bismuth Iodide Heterojunction

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 23:18

In recent years, photocatalysis has attracted widespread attention in environmental control and energy development. Zinc tungstate, as an important photocatalyst, has shown good photocatalytic activity in the photolysis of water and degradation of organic pollutants, and has become a research hotspot at home and abroad.

Mesoporous Molecular Sieve Tungsten Carbide Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 23:07

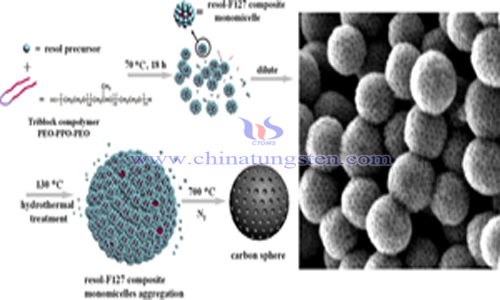

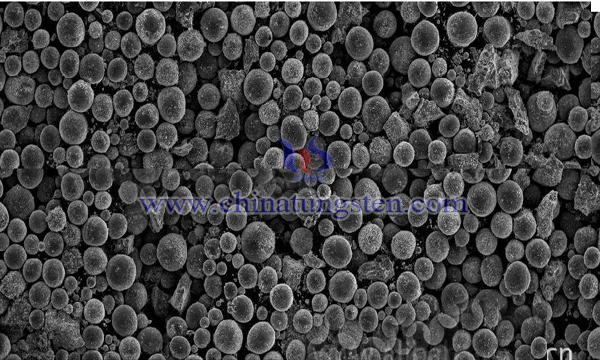

Tungsten carbide is a kind of important transition metal carbides, which has the catalytic properties similar to noble metals. It has shown excellent catalytic performance in oil, gas hydrodesulfurization, denitrification, hydrocarbon isomerization and other reactions, and is the focus of attention.

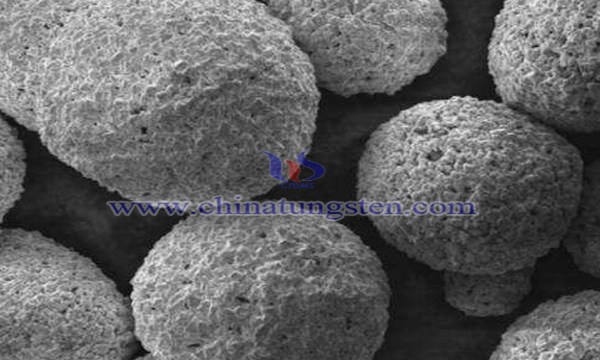

Near Spherical Tungsten Powder Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 23:02

Tungsten metal has a series of excellent properties such as high hardness, high strength, low vapor pressure, good corrosion resistance and high temperature corrosion resistance. The tungsten porous body made from it has excellent dimensional stability and durable life, and has been widely used in the fields of electronics, aviation, weapons and other applications.

sales@chinatungsten.com

sales@chinatungsten.com