Tungsten Titanium Alloy Preparation by Plasma Sintering

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:54

As a sputtering target for copper wiring diffusion barrier layer, W-Ti alloy has many requirements in structure and properties. A large number of experimental results show that the grain size and Ti-rich phase content of WTi alloy structure are the main factors affecting the performance of the barrier layer.

Molybdenum Tungsten Complexes Application in Anticancer and Antineoplastic Drugs

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:45

Molybdenum is a trace element of life needed by organisms. Lack of molybdenum in the human body can lead to a series of diseases. Such as Keshan disease, kidney stones, Kashin-Beck disease, hypertension and diabetes. In particular, molybdenum deficiency can increase the incidence of cancer and cancer.

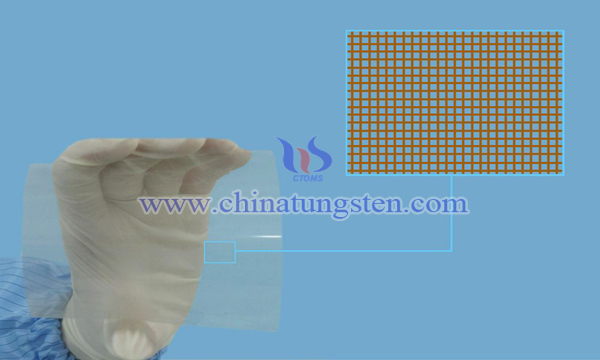

How to Prepare Porous Tungsten Trioxide Thin Film Electrode

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:37

In the worsening global situation of greenhouse effect and environmental pollution, photocatalytic hydrogen production using solar energy, which is rich in nature, is one of the new energy ways for sustainable development. Photoelectric catalytic water decomposition is used to produce hydrogen from solar energy and water. There are no by-products, and hydrogen and oxygen can be obtained at the two poles separately without pollution, showing strong advantages and development potential.

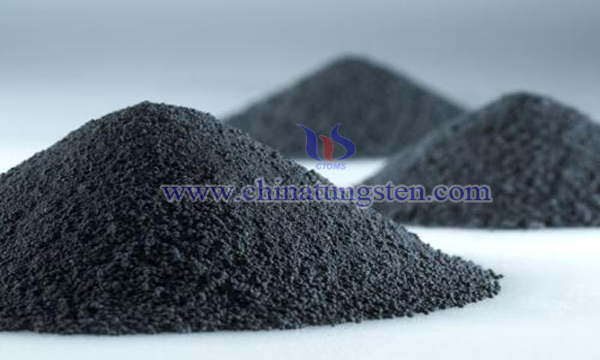

Ultrafine Tungsten Carbide by Direct Reduction Carbonization Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:32

Ultra-fine cemented carbide made from ultra-fine tungsten carbide powder has the characteristics of high strength and high hardness, which effectively solves the contradiction between hardness and strength of traditional cemented carbide. It is widely used in making micro-drills for integrated circuit board, printing needles for dot matrix printers, precision tooling, cutting tools for difficult-to-process materials, woodworking tools, medical dental drills and so on.

Tungsten Carbide-Cobalt Cermet Coating Powder Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:26

The traditional method of hard chromium plating on metal surface has many problems, such as complex process, low deposition rate, difficult to deposit thick coatings, softening of chromium plating layer when the temperature reaches above 260 ℃, leading to a significant decrease in wear resistance and environmental pollution caused by hard chromium plating.

Efficient Catalysis of 2-Acetylthiophene over Aluminum Phosphotungstate Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:19

2-acetylthiophene is an important intermediate in organic synthesis. It has been widely used in the synthesis of medicines and pesticides, such as antibiotics, plant growth regulators, androgen inhibitors, fungicides and herbicides.

Tetracycline Wastewater Purification by Nano Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:10

Tetracycline antibiotics are a kind of broad-spectrum antibiotics produced by Streptomyces, including aureomycin, oxytetracycline, tetracycline and so on. The use and abuse of these antibiotics make most of the antibiotics not fully absorbed by animals or human body and directly discharged into the water body, which has a serious impact on the environmental system and is regarded as a typical micro-polluted organic matter. The removal of antibiotics represented by tetracyclines has become an urgent scientific research problem.

Propylene Production with Supported Silicotungstic Acid Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 21:47

Propylene is one of the most important basic organic raw materials after ethylene. Its maximum use is to produce polypropylene, accounting for about 60%, followed by acrylonitrile, propylene oxide, isopropyl benzene, isopropanol, carbonyl alcohol and other downstream products.

How to Reduce Agglomeration of Ultrafine Tungsten Carbide Powder

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 21:40

Ultrafine tungsten carbide powder commonly produced on the market is produced by carbon tube furnace or molybdenum wire furnace after mixing nanometer, ultrafine or fine tungsten powder with carbon black, then crushed by ball mill, and finally screened to obtain fine tungsten carbide powder products.

Manganese Tungstate by Molten Salt Electrolysis Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 21:33

Manganese tungstate is an important functional material with tungsten-manganese-iron structure. It has broad application prospects in photoluminescence, optical fibers, Polyferrous materials, photocatalysts, scintillators, humidity sensors and magnetic materials.

sales@chinatungsten.com

sales@chinatungsten.com