Tungsten Carbide/Titanium Dioxide Composite Catalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 16:04

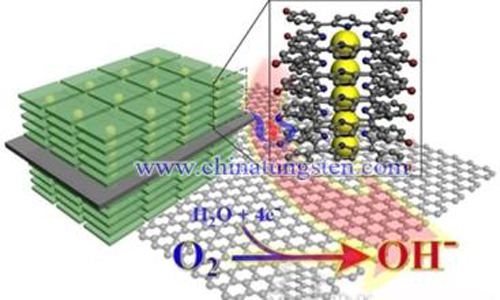

Tungsten carbide can catalyze hydrogenation, hydrogenolysis and reforming of alkanes. At the same time, nano-tungsten carbide has high electrochemical activity and good catalytic effect in low temperature acidic medium. It is acid-resistant, high temperature-resistant and CO-poisoning-resistant. It also shows catalytic oxidation performance for hydrogen, water and methanol oxidation.

A domestic listed company has successfully developed a method to prepare tungsten carbide and titanium dioxide composite catalysts using waste materials, which can achieve uniform liquid-liquid mixing of titanium liquid and ammonium tungstate solution, and ultimately improve the platinum-like catalytic activity of tungsten carbide by utilizing the photocatalytic properties of titanium dioxide.

(1)Take the waste catalyst containing tungsten (the second stage catalyst for acrylic acid production by oxidation of waste propylene and the catalyst RN-1,3581 for petroleum hydrogenation), remove the water, organic matter and carbon in the catalyst, control the temperature at 600 ℃, roast for 8 h, then roast it at 700 ℃ for 8 h until all tungsten sulfide is oxidized to tungsten trioxide; take the roasting material and grind it after cooling, and leach it with 18.5% ammonia water. The leaching temperature is 78 ℃ and the leaching time is 8 h until all tungsten trioxide is dissolved. The leaching solution is kept at 56 ℃ for 10 h to precipitate impurities such as silicon, phosphorus and iron, and then filtered. The leaching solution is ammonium tungstate solution with a concentration of 30%.

(2)Titanium-containing waste ash box material was mixed with solid ammonium sulfate and concentrated sulfuric acid with mass fraction of 98%. The solid ammonium sulfate and concentrated sulfuric acid were mixed at the ratio of 1:1 and 30%. The solid ammonium sulfate and concentrated sulfuric acid were mixed at the ratio of 1:2 by weight. The liquid titanium is prepared by heating to 200 ℃, stirring until the ash box material is completely dissolved and cooling to room temperature.

(3)Titanium solution was taken, mixed with inorganic dispersant solution and organic surfactant solution, stirred and heated until boiling, then cooled to 70 ℃. Then ammonium tungstate solution was added, stirred for 2 hours, and the mixed solution was obtained.

(4)The mixed solution was heated for 3 hours, filtered and washed several times, then the composite powder was obtained by vacuum drying. At this time, titanium in the composite powder exists in the form of hydrated titanium dioxide powder.

(5)Composite powders were carbonized in a reduction furnace with reducing gases. The carbonization temperature was raised to 500 ℃ at a heating rate of 3 ℃/min and kept for 3 hours, so that the non-carbon elements in ammonium tungstate solution and titanium dioxide composite powders were discharged in the form of hydrogen peroxide or NH3, and the composite catalyst of tungsten carbide and titanium dioxide was prepared.

By preparing the composite catalysts of tungsten carbide and titanium dioxide, the electrocatalytic performance of tungsten carbide was improved, and its platinum-like catalytic activity was enhanced. Therefore, it is hopeful to be used in heterogeneous catalysis and electrocatalysis instead of noble metal catalysts.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com