New Tungsten Alloy Preparation Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 April 2019 22:33

Tungsten alloys are alloys based on tungsten and composed of other elements. Among the known metals, tungsten has the highest melting point, good high temperature strength, creep resistance, thermal conductivity, electrical conductivity and emission properties. Tungsten has a larger proportion than ordinary metals. In addition to a large number of cemented carbides and alloying additives, tungsten and its alloys are widely used in the electronics and light source industries, as well as in the aerospace, foundry, weapons and other departments to produce rocket nozzles, die-casting dies, armour-piercing core, contacts, heaters and heat shields.

Gadolinium Tungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 22:05

Gadolinium tungstate is an important inorganic nanocluster. Its English name is Gadolinium Tungsteate and its chemical formula is Gd2O12W3. It is composed of transition metal tungsten and rare earth element gadolinium connected with oxygen-containing groups. It has unique molecular structure, unique fluorescence properties, excellent water solubility and ultra-small molecular size. It is widely used in biomedicine, analysis, optics and catalysis. At present, the most potential applications are known to be radiotherapy or photothermal therapy for cancer.

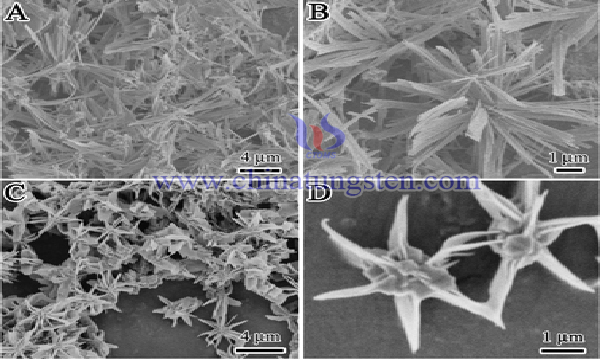

Ultrafine Scaly Crystal Tungsten Disulfide Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:53

Tungsten disulfide is a fine gray crystalline or powder with metallic luster. It belongs to hexagonal crystal system. It has semiconductor and diamagnetic properties, layered structure, easy dissociation, and lubricating properties similar to graphite. It is mainly used as lubricant. Its performance is better than molybdenum disulfide, its friction coefficient is lower and its compressive strength is higher. Equipment used alone in high temperature, high pressure, high speed, high load and in chemical active medium.

Nano Binary Molybdenum Tungsten Composite Oxide by Hydrothermal Method Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:48

Transition metal oxides can be used in various fields. Molybdenum oxide and tungsten oxide, as two important transition metal oxides, have attracted the attention of scholars and experts in the fields of photocatalysis and gas sensors for a long time. In the past few years, it has been found that the properties of binary molybdenum tungsten oxide (MoxW1-xO3) materials can be greatly improved due to the "synergistic effect" of the two elements. Therefore, by changing the composition and structure of materials, we can make this "synergistic effect" play a stronger role.

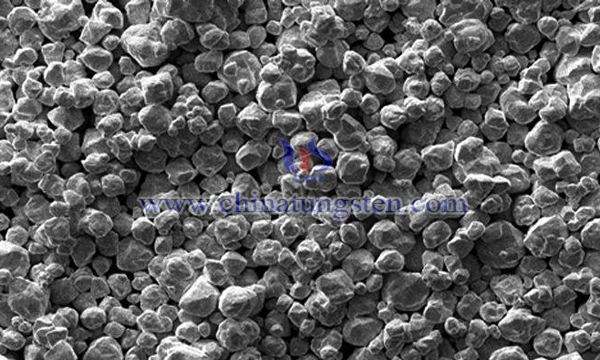

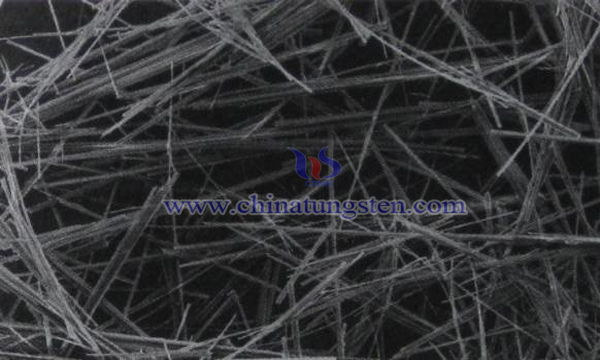

Fibrous Tungsten Carbide Nanoparticles Synthesis

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:40

Tungsten carbide is the main raw material for the manufacture of cemented carbide products, and its particle size has a decisive influence on the properties of cemented carbide products. The preparation of nano-tungsten carbide has become the main way to improve the strength and toughness of cemented carbide products. Cemented carbide is brittle material. There is a contradiction between its hardness and strength. High hardness leads to low strength, while high strength leads to low hardness.

Solid State Reaction Sintering of Zirconium Tungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:34

At present, the main methods for preparing zirconium tungstate are solid phase reaction sintering, sol-gel method, hydrothermal method, co precipitation method, microwave synthesis method, combustion method, laser sintering method, spray drying method, etc. Among them, the preparation cycle of sol gel method is too long to be used. The reaction principle of hydrothermal method is complex and the time is long. The coprecipitation process is cumbersome and difficult to control. The solid phase reaction sintering method has the advantages of simple principle, simple operation and limited conditions. Therefore, at present, solid-state reaction sintering method can rapidly and effectively prepare zirconium tungstate.

Tungsten Trioxide Film Material Preparation by Immersion Pulling Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:26

At present, the commonly used preparation methods of tungsten trioxide thin films are atomic layer deposition, chemical vapor deposition, electrodeposition and so on. However, the tungsten trioxide thin film method developed based on the above methods requires high equipment, complex preparation process, high cost, and can not prepare large-area films.

Domestic Production of SCR Denitrification Catalyst for Vehicles and Ships

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:18

PM2.5 is an important factor affecting air quality. Coal-fired power plants, oil-fired automobile ships, especially diesel engine automobile ships, are the sources of PM2.5. With the development of China's automotive industry and the increase of car ownership, the treatment technology of automotive exhaust has attracted more and more attention.

New Tungsten Alloy Preparation Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:06

The traditional preparation of tungsten alloys is mostly based on sintering technology, which leads to a series of problems such as low densification, uneven microstructure and limited composition of tungsten-based alloys. It is mainly reflected in the slow preparation speed, low efficiency and high preparation cost.

Rare Earth Lanthanum Adjustment Tungsten Zirconium Alloy Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:01

Tungsten plays an important role in high temperature materials and functional materials. Widely used in the electronics and light source industry, in the aerospace, foundry, weapons and other departments for the production of rocket nozzles, die-casting molds, armour-piercing core, contacts, heaters and heat shields.

sales@chinatungsten.com

sales@chinatungsten.com