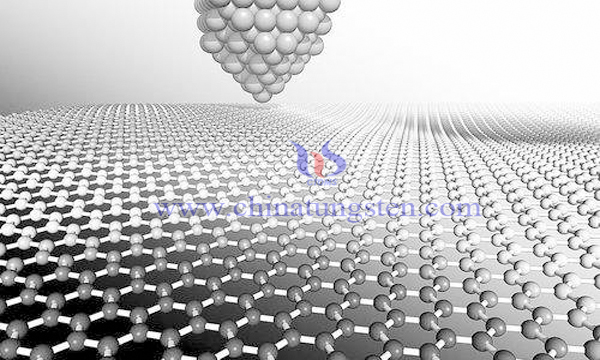

Tungsten Selenide-Graphene-Carbon Nanofibre Composites

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 16:47

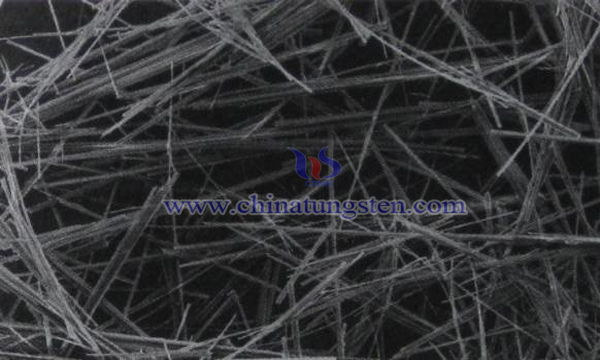

Carbon fiber is a new type of fiber material with more than 95% carbon content. Its quality is lighter than that of metal aluminium, but its strength is higher than that of steel, and it has the characteristics of corrosion resistance and high modulus. It is an important material in national defense, military and civil fields. At the same time, the good conductivity and thermal conductivity of carbon fibers make them have a broad application prospect in the field of energy storage and conversion in the new generation.

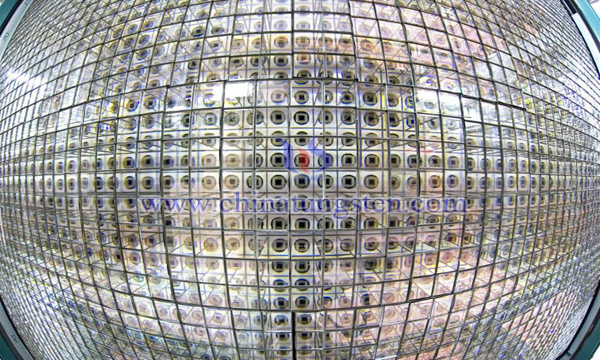

Lead Tungstate Spindle Crystal Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:56

Lead tungstate is an important inorganic scintillator material. Due to its excellent scintillation performance, short attenuation time, high irradiation hardness, high density and low cost, it has been widely used in many fields such as photocatalysis, microwave, scintillator, luminescence, optical fiber, detector and so on.

Trichrome Synthesis of Rare Earth Doped Calcium Tungstate Fluorescent Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:51

Fluorescent powder has important application value in many sectors of national economy. The most widely used fluorescent lamp, followed by LED display screen. In addition, fluorescent powder can also be used on oscilloscopes and radar fluorescent screens, as well as electronic-photon converters, nuclear radiation displays and X-ray sensitization screens. In short, the use of fluorescent powder is extensive, and its scope of use is expanding year by year.

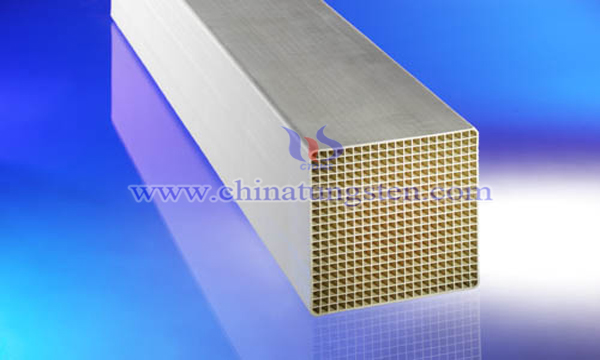

Domestic Titanium Tungsten Powder Preparation Scheme

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:46

Vehicle exhaust contains a lot of nitrogen oxides. It not only causes acid rain, photochemical smog and other environmental problems, but also seriously threatens human health. Therefore, how to remove nitrogen oxides efficiently has become an important topic.

Low Temperature Synthesis of Tungsten Disulfide Nanorods

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:23

Nanostructured materials have unique physical, chemical, electrical, magnetic and mechanical properties and have potential applications in filling materials, drug delivery, catalysis and other fields. Previous studies have shown that transition metal disulfides have unique properties and can be used as photosensitive materials, catalysts, lubricants, cathode materials for high-energy batteries, etc.

New Ideas of "Tungsten" in Foreign Nuclear Fusion Reactor

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:13

Scientists at a British university are experimenting with tungsten in a world-class new facility to help develop a new fusion reactor, ITER. ITER refers to the International Thermonuclear Fusion Experimental Reactor, which is known as the "artificial solar" project. Many countries involved in the research believe that if the "artificial sun" can be realized, it will produce almost unlimited clean energy, which is inexpensive and incalculable.

Tungsten Doped Tin Dioxide Sol Nanocrystals Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 22:55

Tin dioxide is an n-type semiconductor material with good chemical stability and optical anisotropy. It is widely used in gas-sensitive materials, photoelectric materials, lithium-ion battery materials and other fields. By doping, tin dioxide can become semiconductor or conductor, improve its conductivity and spectral selectivity, and expand its application range.

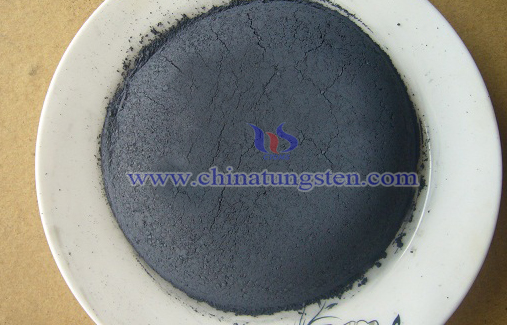

Ultrafine Scaly Crystal Tungsten Disulfide and Its Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 22:48

Tungsten disulfide is a fine gray crystalline or powder with metallic luster. It belongs to hexagonal crystal system. It has semiconductor and diamagnetic properties, layered structure, easy dissociation, and lubricating properties similar to graphite. It is mainly used as lubricant. Its performance is better than molybdenum disulfide. Its friction coefficient is lower and its compressive strength is higher.

Nano Binary Molybdenum Tungsten Composite Oxides Preparation by Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 22:37

Transition metal oxides can be used in various fields. Molybdenum oxide and tungsten oxide, as two important transition metal oxides, have attracted the attention of scholars and experts in the fields of photocatalysis and gas sensors for a long time. In the past few years, it has been found that the properties of binary molybdenum tungsten oxide (MoxW1-xO3) materials can be greatly improved due to the "synergistic effect" of the two elements. Therefore, by changing the composition and structure of materials, we can make this "synergistic effect" play a stronger role.

Fibrous Tungsten Carbide Nanoparticles Synthesis

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 22:21

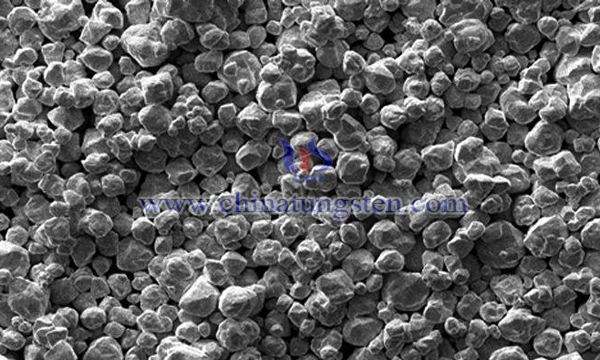

Tungsten carbide is the main raw material for the manufacture of cemented carbide products, and its particle size has a decisive influence on the properties of cemented carbide products. The preparation of nano tungsten carbide has become the main way to improve the strength and toughness of cemented carbide products. Cemented carbide is brittle material. There is a contradiction between its hardness and strength. High hardness leads to low strength, while high strength leads to low hardness.

sales@chinatungsten.com

sales@chinatungsten.com