Solid State Reaction Sintering of Zirconium Tungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 22:08

Zirconium tungstate is a special kind of negative thermal expansion material with isotropic negative thermal expansion property. It reaches thermodynamic stability in the temperature range of 1378K-1530K, and exists in metastable state at room temperature. At present, three kinds of phases have been found: low temperature cubic phase a-ZrW2O8, high temperature phase beta-ZrW2O8 and high pressure phase gamma-ZrW2O8. Their thermal expansion coefficients are aalpha=-8.7x10-6/K, abet=-4.9x10-6/K and agamma=-1x10-6/K.

Tungsten Trioxide Thin Films Preparation by Impregnation and Drawing Method

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 21:58

At present, the commonly used preparation methods of tungsten trioxide thin films are atomic layer deposition, chemical vapor deposition and electrodeposition. However, the tungsten trioxide thin films based on the above methods require high equipment, complex preparation process, high cost, and can not prepare large-area films. Therefore, it is imperative to develop a tungsten oxide PEC semiconductor electrode material with simple production process, low cost, high purity and high photoelectric conversion efficiency.

Domestication of SCR Desalination Catalyst for Vehicles and Ships

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 21:48

PM2.5 is an important factor affecting air quality. Coal-fired power plants, oil-fired automobile ships, especially diesel engine automobile ships, are the sources of PM2.5. With the development of China's automobile industry and the increase of automobile ownership, the treatment technology of automobile exhaust has attracted more and more attention.

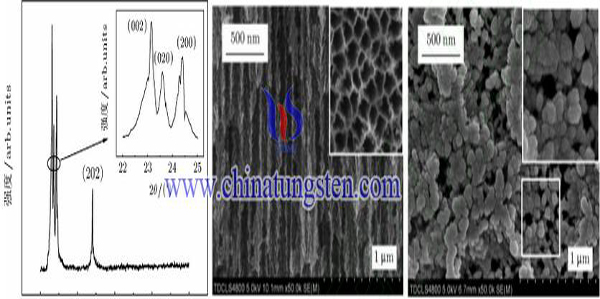

Nano Tungsten Trioxide Preparation by Electrochemical Anodic Oxidation

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 21:23

Because of its high chromogenic efficiency and low price, nano tungsten trioxide has always been the preferred electrochromic compound. In addition, as a photocatalytic hydrogen production electrode material, nano-tungsten trioxide has also been widely concerned.

Bismuth Tungstate Nanowafers Preparation by Hydrothermal Synthesis

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 21:16

Environmental protection and sustainable development have become important issues that human beings must consider. Photocatalytic technology, as a branch of green chemistry, is an important environmental protection treatment industry in the future.

Tungsten Carbide--Carbon Nanotube Composites

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 22:05

Although tungsten carbide has platinum-like catalytic performance and strong anti-CO poisoning ability, its dispersibility is poor, its specific surface area is small, it is easy to agglomerate, and its conductivity is poor, and its catalytic activity is not ideal. Compared with platinum and other noble metal catalysts, there is still a big gap.

Porous Silicon-based Tungsten Oxide Nanorod Composite Gas Sensing Material

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 21:55

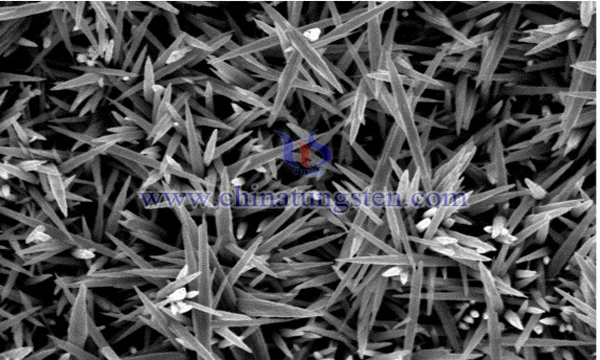

The results show that the one-dimensional tungsten oxide nanostructures have large specific surface area, surface activity and strong gas adsorption capacity, which can accelerate the reaction between gases, further improve the sensitivity and effectively lower the working temperature. In order to obtain such a high performance gas sensor, the first step is to prepare nanomaterials that can meet these requirements.

Tailings Slurry Treatment by Flocculation Flotation

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 21:47

In the process of scheelite flotation, a large amount of sodium silicate was added as gangue inhibitor or dispersant. The presence of sodium silicate makes it difficult to clarify tailings water, especially for a large number of fine suspended solids to settle under gravity.

Waste Tungsten Powder Recycling Strategy

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 21:41

In the traditional recovery and treatment of waste tungsten powder, the powder waste tungsten powder is first oxidized into tungsten oxide, and then tungsten oxide is dissolved by alkali to form tungstate. In this way, not only the process is complex, but also the efficiency is very low. The oxidation rate of waste tungsten powder is usually less than 50%. Unoxidized tungsten powder needs to be recycled by other methods again.

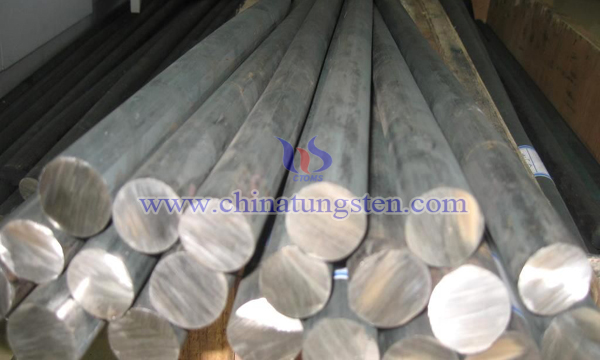

Tungsten Alloy Blank

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 21:36

Tungsten alloy blank refers to tungsten alloy semi-finished products of various shapes. The tungsten alloy blank is further processed to prepare various tungsten alloy products. The main categories include: tungsten alloy billet, tungsten alloy bar, bar, cube, brick, block and tungsten alloy plate, etc. The common tungsten alloy blanks are mainly castings, forgings, profiles, welding parts and so on.

sales@chinatungsten.com

sales@chinatungsten.com