Activated Carbon Supported Silver Phosphomolybdate-Tungsten Heteropoly Acid Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 16:58

With the introduction of the concept of green chemistry, the enhancement of people's awareness of environmental protection and the emphasis on environmental protection, these inorganic acid catalysts are gradually being eliminated. Heteropoly acid and its salts catalysts are a new type of solid acid catalysts developed in recent years. Heteropoly acid is a kind of oxygen-containing polyacid formed by the bridging coordination of heteroatoms (such as P, Si, Fe, Co, etc.) and polyatoms (such as Mo, W, V) through oxygen atoms, such as phosphomolybdenum tungsten, phosphomolybdenum vanadium, silicotungstic acid and silicomolybdic acid.

Silver Nickel Tungsten Carbide Contact

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 16:45

With the development of social economy, there are many applications requiring smart frame circuit breakers to have higher electrical life. Therefore, it is necessary to develop a kind of material with strong resistance to arc erosion as static contacts, which can be used in pairs with AgW50 dynamic contacts, so as to greatly improve the electrical life of intelligent frame circuit breakers and meet the requirements of various applications.

Technological Evolution of Rare Earth Tungsten Electrode Technological Evolution

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 16:25

Tungsten is a kind of high melting point metal with melting point of 3410 ℃, so it becomes a special process to make it into regular shape. The addition of rare earth elements to tungsten can effectively improve the performance of materials, but the difficulty of forming and processing is obviously increased. Moreover, the preparation of rare earth tungsten electrodes from rare earth tungsten slabs still needs a long process.

Nano Flake Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 16:15

In recent years, with the rapid development of social economy, the impact of human activities on the earth has become more and more serious, making the pollution of the earth more and more serious, especially the water pollution. In order to solve this problem, people began to study photocatalyst, hoping that it can alleviate the environmental pollution.

Copper Phosphotungstate--Attapulgite Composite Oxidative Desulfurization Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 16:07

Oxygenated desulfurization (ODS) technology has mild operating conditions, high selectivity, and no need of hydrogen, which reduces operating costs. It has high desulfurization efficiency for benzothiophene compounds which are difficult to remove in catalytic hydrogenation, and can meet the requirements of ultra-deep desulfurization. It has good application prospects. Catalyst is a key factor in catalytic oxidation desulfurization. Catalysts for the oxidation of hydrogen peroxide are usually organic acids such as formic acid and acetic acid, heteropoly acids such as phosphotungstic acid, metal oxides, etc.

Improved Process for Preparing Nano Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 16:01

Tungsten carbide is the main raw material for the manufacture of cemented carbide products, and its particle size has a decisive influence on the properties of cemented carbide products. The preparation of nano tungsten carbide has become the main way to improve the strength and toughness of cemented carbide products.

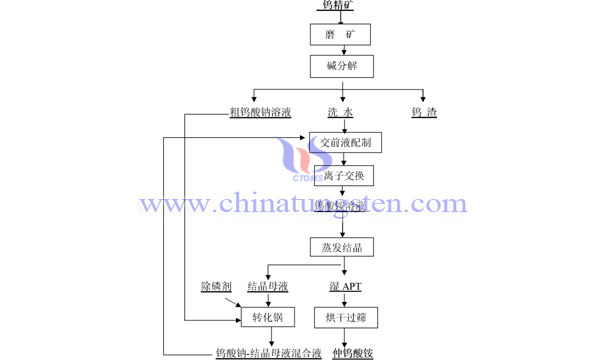

Phosphorus Removal Process Before Ion Exchange

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 15:54

With the shortage of mineral resources, the national environmental protection policy has become increasingly stringent, and attention has been paid to the upgrading of scheelite smelting methods. The development and application of tungsten smelting processes with high metal yield and low energy consumption, which can achieve closed circuit recycling and zero emission, can not only create profits for enterprises, but also preserve wealth for future generations.

Phosphorus Removal Slag Processing in Tungsten Smelting

- Details

- Category: Tungsten Information

- Published on Saturday, 20 April 2019 15:43

At present, with the shortage of tungsten mineral resources, especially the rising price of tungsten products in recent years, the rational comprehensive utilization of tungsten-containing phosphorus removal slag produced in the production process of ammonium paratungstate (APT) can not only create profits for the reuse of enterprise resources, but also create wealth for the country.

Tungsten Titanium Alloy by Plasma Sintering Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 April 2019 22:46

Tungsten titanium alloy prepared by plasma sintering as a sputtering target for copper wiring diffusion barrier layer has many requirements in structure and properties. A large number of experimental results show that the grain size and Ti-rich phase content of WTi alloy structure are the main factors affecting the performance of the barrier layer.

Rare Earth Yttrium Regulates Tungsten Zirconium Alloy Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 April 2019 22:40

Tungsten plays an important role in high temperature materials and functional materials. Widely used in the electronics and light source industry, in the aerospace, foundry, weapons and other departments for the production of rocket nozzles, die-casting molds, armour-piercing core, contacts, heaters and heat shields.

sales@chinatungsten.com

sales@chinatungsten.com