Brief Introduction of Nanopore Preparation by Tungsten Tip

- Details

- Category: Tungsten Information

- Published on Monday, 07 January 2019 22:03

The life activities of organisms are mainly carried out by cells, which are isolated from the surrounding environment through cell membranes and maintain a relatively stable internal environment. Cell membranes are mainly composed of lipids arranged into bilayer layers (BLM) and embedded with various functional proteins, which play the roles of material exchange, energy exchange and signal transmission between cells and the external environment.

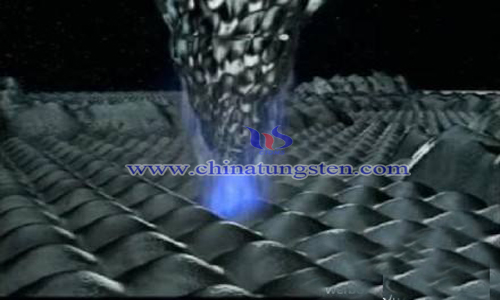

Artificial construction of phospholipid bilayer membranes on solid surfaces or micro-and nano-porous surfaces and the introduction of channel proteins are popular methods to construct biomimetic membranes and study the function of channel proteins. In the process of studying single ion channels, it is necessary to prepare glass nanoporous membranes by encapsulating and removing metal needle tips through glass tubes. Here we need to mention an important equipment - tungsten needle tip.

(1) Preparation of tungsten tip

The tungsten wire about 2.5 cm in length is cut off with forceps and punched with forceps; secondly, the tungsten wire is cleaned with acetone, ethanol and water for 5 minutes to remove the stains on the surface of the tungsten wire; then, the cleaned tungsten wire is inserted into the 0.75M KOH solution as the working electrode, and graphite as the electrode, electrochemical etching is carried out with 25V AC voltage; finally, the etched tungsten wire is obtained. The needle tips were cleaned with acetone, ethanol and water in turn to remove the residual impurities on the needle tips.

(2) Tungsten tip encapsulated in glass tube

The non-etched end of the prepared tungsten needle tip is inserted into the long needle barrel to expose the etched tungsten needle tip. Secondly, the tungsten needle tip is placed in the middle of the tube about 5mm away from the end of the glass tube. The end of the glass tube is heated by butane flame, and then the tungsten needle tip is as close as possible to the end of the tube. Thirdly, the suction pipe of the vacuum pump is connected to the open end of the glass tube. The vacuum degree is greater than 0.1 MPa, and the flame temperature is 1000-1200 ℃. The glass contraction contact can be seen and the tungsten tip can be encapsulated.

(3)Tungsten nanodisk electrode prepared by polishing

The glass disc end surface was polished step by step with water-borne sandpaper and metallographic sandpaper (2, 4, 665 Monitor. When the conductance value increases sharply, it indicates that the tip of the metal needle has been exposed, and the polishing is stopped immediately to obtain the tungsten nanodisk electrode. Finally, the tungsten nanodisk electrode is characterized by cyclic voltammetry scanning curve in KCl solution, and the radius of the tungsten nanodisk electrode is estimated.

(4) Fabrication of glass nanopore by etching encapsulated tungsten needle tip

The prepared glass-tungsten nanodisk electrode was placed in the etching solution and etched with 25V AC voltage until the glass-encapsulated tungsten tip was completely etched and the glass nanopore was obtained.

The glass nanoporous biomimetic membranes have the advantages of low leakage current and high signal-to-noise ratio. They are suitable for the study of biosensor, DNA sequencing, drug screening, channel protein function and so on.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com