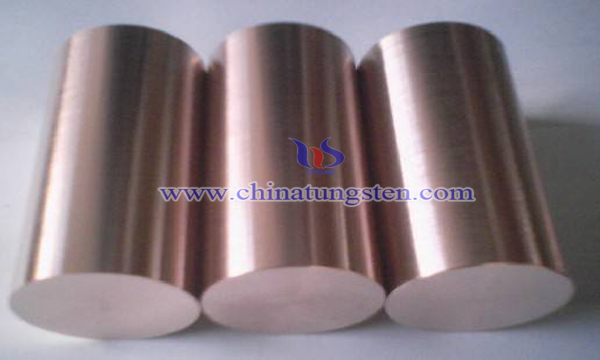

Tungsten Copper Zinc Alloy Material Preparation Scheme

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 16:21

Tungsten-copper composites have high density, low thermal expansion coefficient of tungsten and high conductivity of copper. Their thermal conductivity, conductivity and thermal expansion coefficient can be designed by adjusting the content of tungsten-copper components. Therefore, they are widely used in microwave devices, integrated circuit packaging materials, electrical contact materials and military industry.

Because tungsten and copper are neither solid solution nor compound, it is difficult to produce high density tungsten-copper alloy by conventional sintering method at one time. As a result, tungsten-copper materials are usually manufactured by infiltration method. Although tungsten-copper materials have the advantages of tungsten and copper, they also have their corresponding disadvantages. As the strength of pure copper is lower than 200 MPa, the strength and toughness of W-Cu composites prepared by either infiltration or powder metallurgy sintering are difficult to meet the requirements.

In order to solve the problems of low strength and hardness of W-Cu composites and overcome the shortcomings of low strength and hardness of W-Cu composites, some researchers have designed a W-Cu-Zn alloy composites with both advantages of W and Cu and high strength and hardness as well as its preparation scheme. The process is as follows:

Step 1: Select tungsten powder, copper powder and zinc powder with an average particle size of 2-4 microns, mix them with V-type mixer for 24 hours and then reduce them with hydrogen to obtain a mixture of three metal powders with a purity of more than 95%.

Step 2: Mixed powder is put into graphite mould and sintered in vacuum in spark plasma sintering equipment. The solid phase sintering process is carried out at 800 ℃, 50 ℃/min and 5 min holding time.

step 3, the sintered W-Cu-Zn alloy material is continuously heat treated in the spark plasma sintering equipment. The heat treatment temperature is 600 ℃ and the holding time is 3h. Then, the tungsten copper zinc alloy material composed of tungsten-copper-zinc binder phase is obtained by cooling to room temperature with the furnace.

The main point of the scheme is to use brass instead of pure copper as the bonding phase in W-Cu composites. Brass and tungsten are coated and penetrated with each other. The content of tungsten is 60%-80%, and the rest is brass. The material is treated by electric pulse heat treatment with spark plasma sintering equipment, and the phase structure of brass bonding phase in W-Cu-Zn alloy material is controlled to adjust the strength and toughness of the material, so as to achieve the goal of improving the strength and toughness of the material. To achieve a better effect.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com