Tungsten Trioxide Nanotubes Preparation by Template Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 21:54

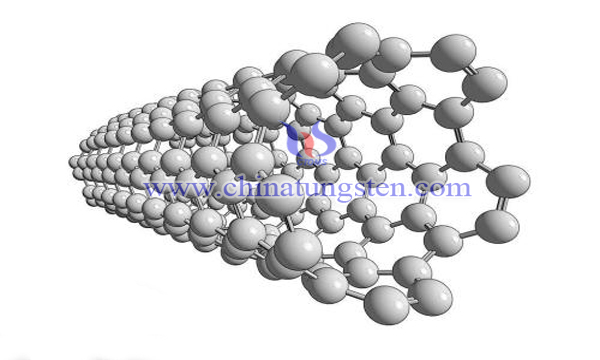

Tungsten trioxide nanomaterials are often used to fabricate high-performance nanodevices because of their unique properties. One-dimensional nanomaterials have become a research hotspot of nanomaterials. At present, the preparation methods of WO3 mainly include V-L-S method, L-L-S method, template method and so on. Template method has the advantages of low cost, suitable for large area ordered array units, and has become the mainstream.

However, the template method has the disadvantage of poor controllability, which increases the complexity of the preparation process and reduces the yield of the product. Some researchers provided a preparation method of tungsten trioxide nanotubes, which solved the problem of low yield of tungsten trioxide nanotubes prepared by existing template method. Its main process needs to go through the following steps:

First, ammonium tungstate is dissolved in distilled water at a mass ratio of 1 to 2:100 to prepare ammonium tungstate aqueous solution; second, the anodic alumina template is immersed in the aqueous solution of ammonium tungstate prepared by step 1, in which the immersion temperature is 30-40 ℃ and the immersion time is 15-20 days; third, the anodic alumina template treated by step 2 is extracted from the aqueous solution of ammonium tungstate and gradually heated to 500-54 in a muffle furnace. 4. Tungsten trioxide nanotubes can be obtained by gradually cooling the anodic alumina template treated in step 3 to room temperature in the furnace and collecting the oxide on the surface of the anodic alumina template with a scraper. More specific laboratory operations are as follows:

Ammonium tungstate solution was prepared by dissolving ammonium tungstate in distilled water at a mass ratio of 1.5:100. Anodic alumina template was immersed in ammonium tungstate aqueous solution at 35 ℃ for 18 days. Anodic alumina template was extracted from ammonium tungstate aqueous solution and gradually heated to 520 ℃ in muffle furnace. The heating rate of muffle furnace was 42 ℃/min and the treated anode was kept for 4.5 H. Tungsten trioxide nanotubes were prepared by collecting oxide on the surface of anodic alumina template with scraper.

By controlling the immersion temperature, the adhesion of ammonium tungstate on the anodic alumina template was increased, and tungsten trioxide nanotubes with regular shape were prepared. The yield of tungsten trioxide nanotubes was increased, and the cost of finished products was reduced.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com