Mesoporous Supported Phosphotungstic Acid Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 05 April 2019 20:00

With the rapid development of chemical industry, the variety and demand of ketals are increasing. Ketal is a kind of intermediate which can be used for carbonyl protection of organic compounds or pharmaceutical industry, even as a special reaction solvent. The synthesis of ketals is usually catalyzed by strong acid, which is synthesized by ketones and alcohols. The catalysts used are sulfuric acid, phosphoric acid, hydrogen chloride gas and p-toluene sulfonic acid. The advantage of the catalysts is that they are cheap and easy to obtain. However, the reaction easily produces wastewater which pollutes the environment and has strong corrosion effect on the equipment.

Ferric Oxide-Tungsten Disulfide Nano Composite Lubricant

- Details

- Category: Tungsten Information

- Published on Friday, 05 April 2019 19:49

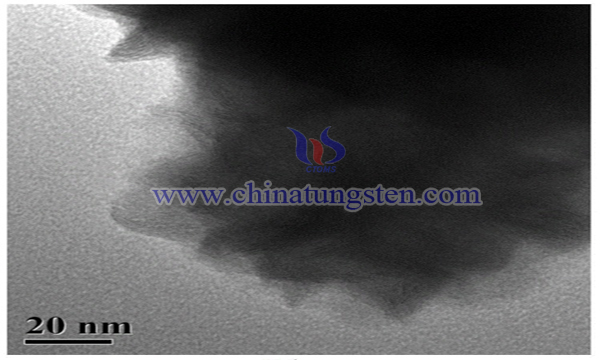

With the deepening of human exploration into space, more and more space vehicles are sent into space. NASA pointed out that the abnormal or failure of spacecraft due to lubrication failure has become an important factor affecting the effective service time of spacecraft. Therefore, how to maintain good lubrication of key components of spacecraft is a very important issue.

Nano Monolayer Tungsten Disulfide Hydrothermal Synthesis

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 April 2019 23:02

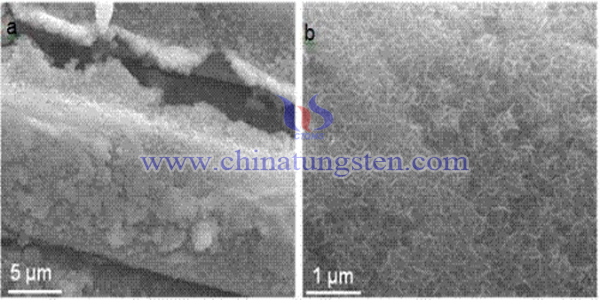

Supercapacitor is a new, efficient and practical energy storage device between battery and traditional capacitor. It has the advantages of fast charge-discharge speed, high power density, long service life, wide temperature window and friendly environment. In recent years, flexible supercapacitor has attracted more and more attention due to its unique advantages.

Tungsten Trioxide Nanofibers Preparation with Core-shell Structure by Electrospinning

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 April 2019 22:55

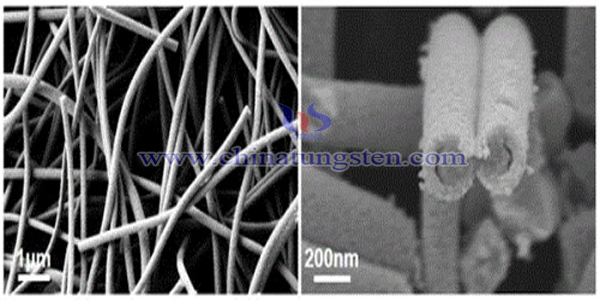

Semiconductor photocatalysts are highly praised for their stable physical and chemical properties, wide distribution on the earth, easy access, low cost and no secondary pollution. As a member of transition metal oxides, tungsten trioxide (WO3) is an indirect bandgap n-type semiconductor material with a band gap of 2.2-2.8eV. It has good absorption of visible light, so it is a very promising semiconductor photocatalyst.

Bismuth Trioxide - Bismuth Tungstate Heterojunction Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 April 2019 22:48

Bi2WO6, as a kind of p-type semiconductor material, has perovskite lamellar structure. Its band gap is about 2.7eV. Bi2WO6 has strong absorption in the visible region with wavelength greater than 420nm. It can use both ultraviolet and visible light in sunlight. It is more and more popular among researchers. However, due to poor adsorption, the separation efficiency of photogenerated carriers is low.

Silver Carbonate-Silver-Tungsten Trioxide Ternary Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 23:08

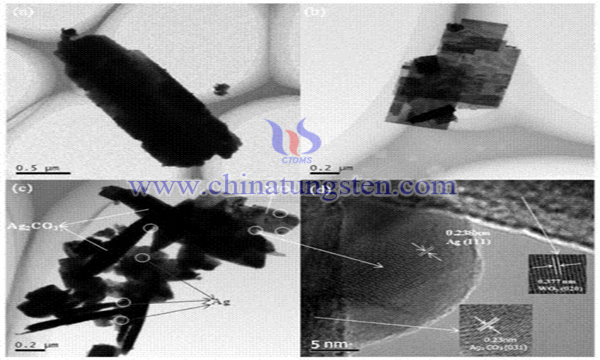

The application of semiconductor photocatalyst in the degradation of toxic and harmful organic pollutants is of great significance for solving environmental pollution. However, broadband gap and low quantum efficiency are still the "bottlenecks" of photocatalysts.

Tungsten Disulfide Nanosheet-Graphene Heterostructure Composites

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 23:03

Graphene is the thinnest and strongest material known in nature. Graphene has high light transmittance, only about 2.3% light absorption, extremely high electron mobility (15,000 cm2/v * s) and very low resistivity. It is a new generation of transparent conductive materials.

Coarse-grained Tungsten Carbide Powder Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 22:55

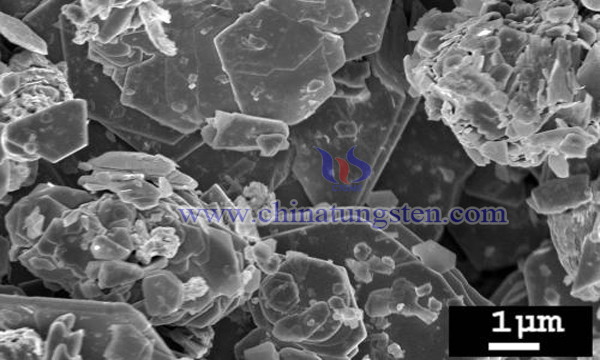

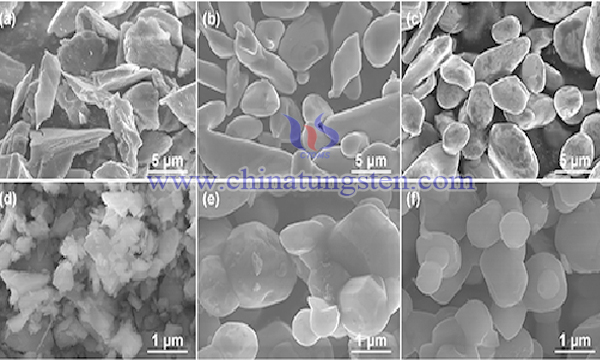

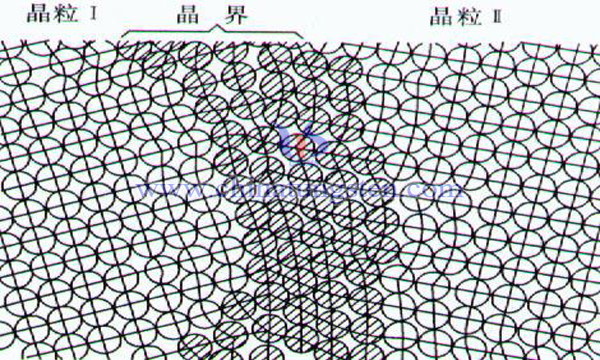

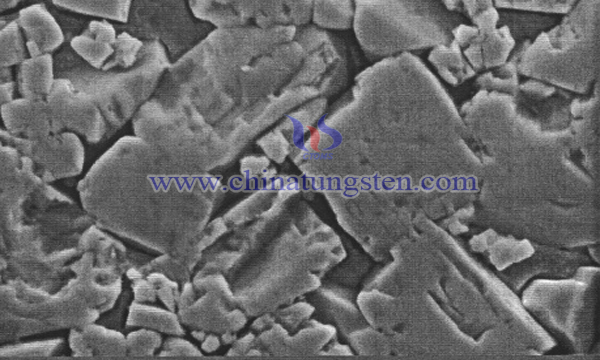

At present, the main production mode of tungsten carbide powder is to mix tungsten powder with carbon powder for a long time in a high temperature environment with a protective atmosphere to obtain tungsten carbide powder with grain size of 2-5 micron. However, it is difficult to form a complete single grain of tungsten carbide with grain size of more than 10 micron, which has become a bottleneck restricting the production of coarse single crystal tungsten carbide mining cemented carbide tools.

New Nano Sized Tungsten Molybdenum Sulfide Hydrogenation Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 22:48

Suspension bed hydrotreating technology is an advanced technology for preparing liquid fuel oil from heavy unconventional oil (residue, heavy oil/superheavy oil, shale oil, coal tar, sandstone oil, oil sand asphalt, etc.). Suspension bed hydrogenation process requires catalyst with high activity, high dispersibility, high stability and good economy. It is a challenging task to prepare catalyst for suspension bed hydrogenation process.

New Tungsten Tin Alloy Shotgun Bullet Core

- Details

- Category: Tungsten Information

- Published on Saturday, 30 March 2019 23:34

Traditional shotgun bullets usually use steel balls or shot putts with diameter of 2 mm-8 mm, and tungsten alloy balls with high specific gravity are used individually.

sales@chinatungsten.com

sales@chinatungsten.com