Tungsten Trioxide Nanofibers Preparation by Electrospinning

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 18:27

Tungsten oxide (WO3) is an indirect bandgap n-type semiconductor material with a band gap of 2.2-2.8eV. It has good absorption of visible light, so it is a very promising semiconductor photocatalyst. In common practice, metal ions are doped into semiconductor photocatalysts, and the recombination of electron-hole pairs can be significantly inhibited by IFCT effect, which can greatly improve the photocatalytic activity of photocatalysts.

Electrospinning technology is a fast and simple method for preparing nanofibers. It has many advantages, such as simple manufacturing device, low spinning cost and various kinds of spinnable materials. It has great progress not only in laboratory research, but also great potential for industrialization. Therefore, it is of great industrial value and social significance to prepare tungsten trioxide nanofibers in batches by electrospinning and use them as photocatalysts.

According to the deficiency of the catalytic activity of tungsten trioxide nanofibers as catalysts in the existing technology, researchers designed a preparation method of micro iron doped tungsten trioxide nanofibers photocatalyst. The design of the method is as follows:

3.5G ammonium metatungstate was dissolved in 10 ml deionized water, and polyvinyl pyrrolidone (PVP) with molecular weight 13000 000 was added. The precursor solution was obtained by stirring the solution to be uniform and transparent. Then white cloth-like primary spun fibers were obtained by uniaxial electrospinning with voltage of 20KV, receiving distance of 15cm and propulsion speed of 0.02ml/min. The primary spun fibers were placed in a tubular furnace. Tungsten trioxide nanofibers were synthesized by calcining at 600 ℃ under medium vacuum, heating rate of 3 / min, holding for 0.5 hours and cooling naturally to room temperature. FeCl3 solution of 0.03g/L was prepared, 50 ml was added to 0.5g tungsten oxide nanofibers, soaked at 85 for 3 hours on the heating table, then filtered, and finally dried in an air drying chamber at 110 for 5 hours, tungsten trioxide nanofibers doped with trace iron were obtained.

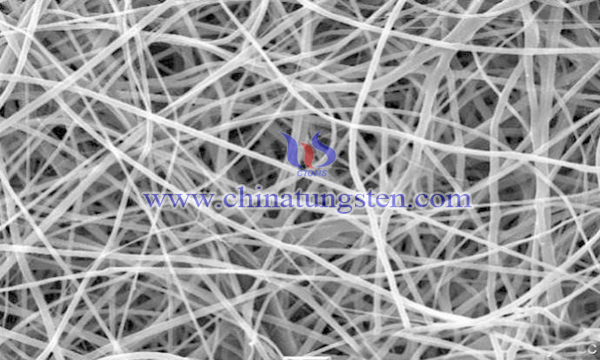

Combined with electrospinning technology and impregnation method, the cost is low, water is used as solvent, green and environmental protection, and the operation is simple. The prepared trace iron-doped tungsten trioxide has not changed the network distribution of tungsten trioxide, the morphology is stable, the diameter distribution is uniform, and the photocatalytic degradation performance of tungsten trioxide is greatly improved.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com