SCR Vanadium Titanium Tungsten Catalyst Recovery

- Details

- Category: Tungsten Information

- Published on Saturday, 15 December 2018 20:39

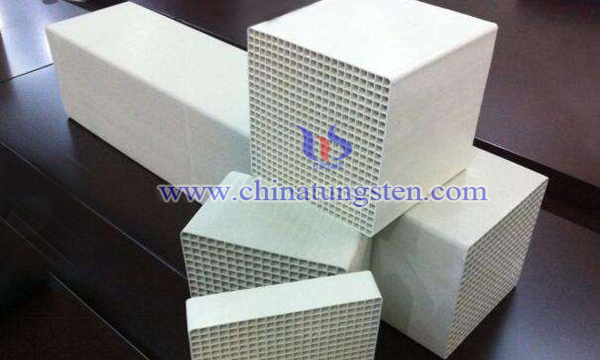

Nitrogen oxides (NOx) are recognized as one of the major sources of atmospheric pollution, including combustion fumes and automobile exhaust. Monolithic vanadium-titanium based catalysts have been widely used in the removal of NOx from flue gas or tail gas. The NOx can be removed by selective catalysis of NH3 to N2. The catalyst is supported by titanium dioxide (usually 80-90% of the total mass), V2O5 (1-2%) and WO3 (5-10%). Initial investment of catalysts in denitrification projects usually accounts for 30-50% of total investment.

The service life of vanadium titanium tungsten catalysts is usually about 3 years. In addition to ammonia consumption, the main cost of SCR operation is the replacement of catalysts. Catalyst deactivation can be divided into reversible poisoning deactivation and irreversible poisoning deactivation. The former can be regenerated by means of back blowing, ash removal, water washing and vanadium supplementation after acid washing, so that the denitrification rate of the catalyst can be restored to over 90% of the original and reused at a cost of 20-30% of the total replacement cost. However, a large number of SCR denitrification catalysts are not renewable or destroyed in the process of regeneration and need to be abandoned. It is estimated that after 2018, the annual abandonment of SCR catalysts in China will reach 78,000 tons. Direct waste of SCR denitrification catalyst not only causes environmental pollution, but also causes waste of rare metal vanadium and tungsten.

To solve this problem, some scholars have provided a method for recovering vanadium and tungsten from waste Vanadium-Titanium-based denitrification catalysts containing tungsten, including the following steps:

The waste Vanadium-Titanium-based denitrification catalyst containing tungsten was crushed, ground and screened. The powder with a particle size of 100-120 mesh was selected. 5wt% hydrogen peroxide was added to the catalyst powder. The molar ratio of hydrogen peroxide to vanadium in the catalyst was 10:1. After 3 hours of full stirring, some vanadium in the catalyst reacted with hydrogen peroxide to form pervanadic acid and filter cake was obtained (1). (1) and pervanadate filtrate containing hydrogen peroxide. H2SO4 was added to the filtrate (1) to adjust its pH value to 4.0, then heated to 70 ℃. The pervanadic acid was decomposed into V2O5 at constant temperature for a certain time. The precipitation of V2O5 and the filtrate (2) were filtered, and the filtrate (2) was mixed with hydrogen peroxide for recycling.

The pH value of mixed solution is adjusted to 8 by sulfuric acid solution, and then NH4Cl solution is added to control the molar ratio of V:NH4+ to 1:4. After stirring for a certain time, the precipitation is static. NH4VO3 and filtrate (3) are filtered, concentrated sulfuric acid is added to filtrate (3), the molar ratio of W:H+ is controlled to 1:4, and tungsten is precipitated after stirring for a certain time. Solid tungstic acid was obtained by filtration and WO3 was obtained by calcination of tungstic acid at 210 ℃. The recovery rate of vanadium and tungsten is 93% and 84% by ICP-OES. The process is simple and has the characteristics of high recovery rate, energy saving, environmental protection and low cost. It has wide application prospects.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com