Reconstruction of Tungsten-Nickel Target for Electrochromic Glass

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 15:32

Chromochromism refers to the phenomenon that the optical properties (reflectivity, transmittance, absorptivity, etc.) of materials change reversibly under the action of external electric field or voltage. Electrochromic materials have wide application prospects in smart windows, anti-glare mirrors, optical information storage and other fields.

As an important intelligent sensitive material, electrochromic materials have been in increasing demand in recent years, especially electrochromic glass. Among all the inorganic electrochromic materials, tungsten trioxide (WO3) is the most fully studied, and the related academic papers and patented technologies are the most. It has the advantages of pure color, stable chemical properties and strong adhesion with the substrate. Tungsten trioxide is used as the chromogenic layer in most electrochromic glasses.

Recently, some scholars have proposed a preparation method of electrochromic glass tungsten nickel alloy target, which includes the following steps:

A.Tungsten powder with 99.99% purity and nickel powder with 99.9% purity were prepared. Mixing according to the proportion of W:Ni=6:4, that is, the mass ratio of W powder to Ni powder is 60%, and the mass ratio of Ni powder to Ni powder is 40%. W and Ni powders were loaded into high-energy ball mill to charge pure Ar2 and mixed at 220r/min speed to obtain tungsten-nickel alloy powders.

B.Tungsten-nickel alloy blanks were successfully prepared by cold isostatic pressing of mixed tungsten-nickel alloy powder, pressing to 240 Mpa and holding pressure for 300 seconds.

C.Tungsten-nickel Billet Prepared by cold isostatic pressing is sintered in vacuum sintering furnace. Temperature rises to 1380 ℃ at a rate of 5 ℃/min for 120 minutes.

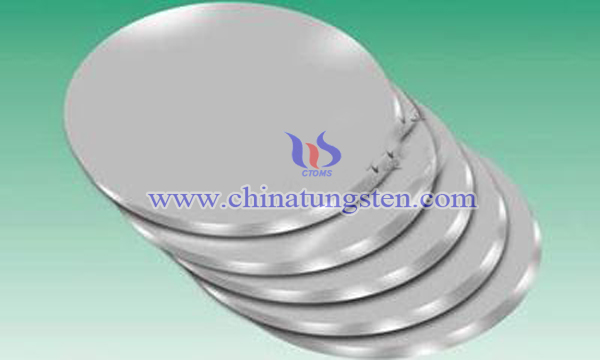

D.Close the vacuum furnace heating system, and the target can be discharged after the furnace is cooled to room temperature. The target with a nickel content ratio of 40% W-Ni alloy is obtained, and the total purity of the target is 99.93%. The obtained tungsten-nickel alloy target has uniform, compact and fine microstructure.

In the sintering process of the existing technology, nickel will form liquid phase, tungsten or solid, which is prone to the problem of non-compact sintering of tungsten and nickel. However, this problem has been solved by the new process, and tungsten-nickel alloy target with uniform structure and high density has been prepared.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com