Phosphotungstic Acid - Titanium Dioxide Photocatalytic Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 22:57

In recent years, with the improvement of people's living standards, a large number of new decorative materials and luxurious and fashionable modern furniture and other household goods continue to enter the interior, resulting in the increasingly serious indoor environmental pollution. At present, the main indoor pollutants such as formaldehyde, benzene, toluene and other volatile organic compounds (voc) seriously exceed the standard, causing great harm to people's health.

How to Recovery Tungsten from Failed Flue Gas Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 22:52

SCR denitrification technology, namely selective catalytic reduction technology, is an environmental protection and pollution control measure adopted by many thermal power plants in China. In the presence of oxygen and the role of catalysts, it can preferentially react with NOx to produce N2 and H2O instead of oxidizing with oxygen in flue gas.

Application of Tungsten Alloy Weight Parts in Racing Cars

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 16:48

Tungsten alloy parts are usually used for the weights of racing cars. Tungsten alloy has high density and small volume, which can improve the sensitivity and controllability of the racing car. Moreover, it has strong wear resistance and long service life. It is easy to process and provides more feasibility for designing tungsten alloy counterweights with multiple specifications and complex sizes.

Advantages of Tungsten Alloy Darts

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 13:21

For darts, high density is very important, because high density darts can make the center of the darts more stable, therefore it is necessary to process high precision with the darts. Tungsten alloy has good machinability; it can satisfy the fast production of the darts. The tungsten alloy darts have the following advantages.

Phosphoric Acid Decomposition of Scheelite

- Details

- Category: Tungsten Information

- Published on Sunday, 24 March 2019 23:05

At present, the decomposition methods of scheelite mainly include acid method, soda method and NaOH method.

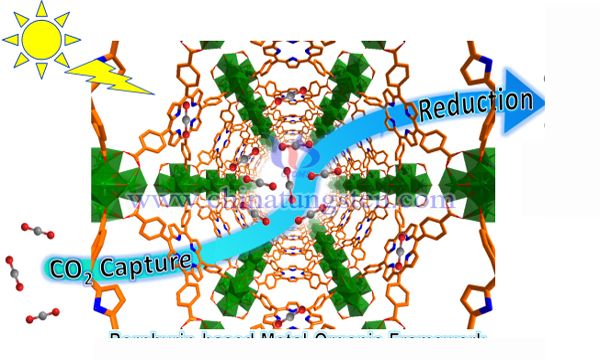

Bismuth Tungstate-Expanded Graphite Lamellar Nanocomposites and Their Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 24 March 2019 22:58

Bismuth tungstate (Bi2WO6) is a layered structure with dielectric, luminescent and ionized conductors. Bismuth tungstate has photocatalytic properties under visible light. Bismuth tungstate can photolysis water and photodegradation organic pollutants under visible light. Therefore, Bismuth tungstate has good application prospects in many related fields.

How to Strengthen Cermets with Tungsten Carbide Molybdenum Tantalum Solid Solution Composite Powder

- Details

- Category: Tungsten Information

- Published on Sunday, 24 March 2019 22:46

TiC cermets consisting of hard phase and bonding phase are the best choice of indexable tool materials for modern high-efficiency and high-speed cutting because of their higher hardness and wear resistance, sufficient strength and toughness, high heat resistance and good chemical stability. However, its fatal weakness is brittleness and toughness is insufficient, and the matching wetting problem between hard phase and bonding phase has not yet been solved.

Zero Radiation Multi-element Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Sunday, 24 March 2019 18:00

Tungsten has high melting point, strong electron emission ability, low electron escape work, high elastic modulus and low vapor pressure, so it is very suitable for non-molten argon arc welding electrode materials.

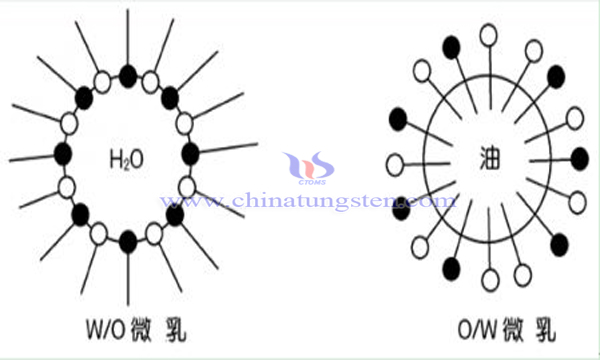

Nano Tungsten Trioxide Preparation by Microemulsion Method

- Details

- Category: Tungsten Information

- Published on Sunday, 24 March 2019 17:48

Because of its large specific surface area and remarkable surface effect, nano-tungsten trioxide has been widely used in various gas-sensing materials, and has become one of the indispensable materials for many high-quality gas-sensing materials. At present, the preparation methods of nano tungsten trioxide are mainly sol gel method, co precipitation method, microemulsion method, physical deposition method and so on. Microemulsion method has been widely applied in recent years because of its simple process.

Finishing of Tungsten-Copper Composite Block in Nuclear Fusion Unit

- Details

- Category: Tungsten Information

- Published on Sunday, 24 March 2019 17:21

In nuclear fusion devices, tungsten is considered as the most promising plasma-oriented material (PFM) because of its high melting point, low sputtering rate, high sputtering energy threshold and no reaction with hydrogen isotopes. The plasma-oriented component (PFC) composed of tungsten monolithic and chromium-zirconium-copper tube is the preferred method for preparing high heat load components of divertor target plate of fusion device.

sales@chinatungsten.com

sales@chinatungsten.com