Tungsten from Sulfide Tailings Recycle

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 22:38

Tungsten deposits are the traditional superior mineral resources in China. There are many kinds of tungsten deposits in China. The causes of mineralization are complex and the forms of mineralization are diverse. With the large-scale development and utilization of tungsten resources and the continuous improvement of beneficiation and metallurgical technology, high-quality primary tungsten resources are consumed in large quantities, the boundary grade of tungsten mining is decreasing day by day, and many associated tungsten resources are reused by people.

New Preparation Technology of Tungsten Carbide Ceramic Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 22:27

With the application of cemented carbides becoming more and more extensive, and the performance requirements tend to be a combination of high strength, high hardness and high temperature resistance. Some enterprises have adopted a new preparation process to prepare tungsten carbide ceramic cemented carbide. The process is as follows:

Negative Expansion Material-Yttrium Tungstate

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 22:06

At present, zirconium tungstate is the most widely studied negative thermal expansion material. AM2O8 series represented by ZrW2O8 has better negative thermal expansion performance and wider temperature range. In the existing academic papers, some scholars have introduced a process of preparing zirconium tungstate by multiple sintering solid-state method. Although this method can obtain single-phase zirconium tungstate products, it requires multiple sintering in the preparation process, and each sintering process parameters are changeable, the process is cumbersome and the conditions are not easy to control, and the requirements are too high.

Ammonium Metatungstate Preparation by Spray Drying Method

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 21:58

Spray drying is a drying method that produces a powder drying product by processing a solution, emulsion, suspension and slurry material in a single process. The main advantages of this method are fast drying rate, short drying time and low material temperature. Its characteristics are that liquid raw materials can directly form powdered products, can be continuously produced in large quantities, without crushing process can directly get products with uniform particle size, excellent solubility and dispersion.

Dicyclopentadiene Dioxide Catalyzed by Quaternary Ammonium Salt of Phosphotungstic Heteropolyacid

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 21:49

Dicyclopentadiene dioxide is a kind of alicyclic epoxide with excellent properties. It has excellent weatherability, heat resistance, high hardness and good electrical insulation. It is used in high temperature casting materials, glass fibre reinforced plastics, adhesives, laminates and packaging of electronic devices. This material is usually prepared by epoxidation of dicyclopentadiene, and strong acid catalyst is needed in the reaction process.

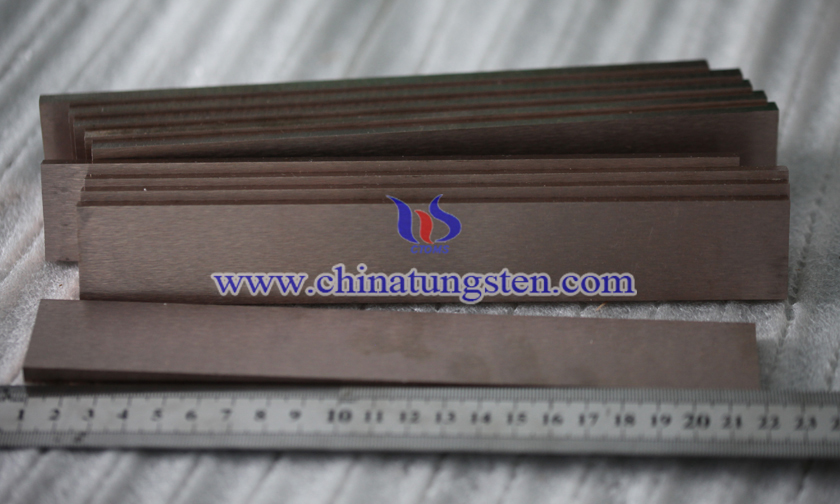

W60 Tungsten Copper Bar

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 14:36

W60 tungsten copper bar is composed of 60% W and 40% Cu, which not only has high density (12.75g/cm3), high hardness (≥HB140), high strength, but also has good conductivity (%47IACS), softening temperature is ≥900℃.

W55 Tungsten Copper Bar

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 14:35

W50 tungsten copper bar is composed of 55% W and 45% Cu, which not only has high density (11.85g/cm3), high hardness (≥HB115), high strength, but also has good conductivity (%54IACS), softening temperature is ≥900℃.

W50 Tungsten Copper Bar

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 14:33

W50 tungsten copper bar is composed of 50% W and 50% Cu, which not only has high density (11.85g/cm3), high hardness (≥HB115), high strength, but also has good conductivity (%54IACS), softening temperature is ≥900℃.

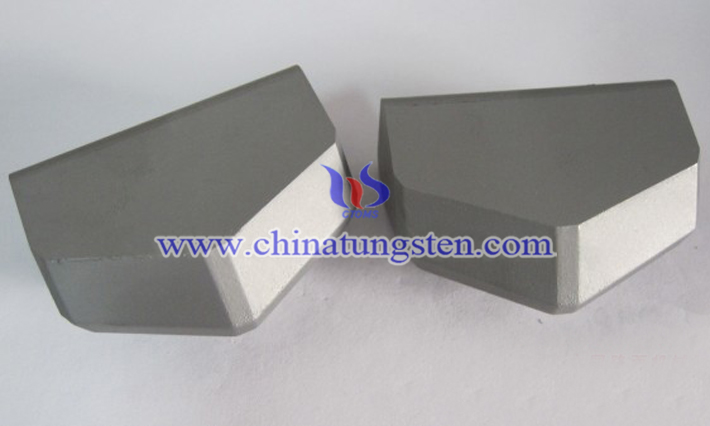

Central South University and Tiejian Heavy Industry Teamed Up to Develop "Iron Tooth Steel Teeth": Tungsten Carbide Shield Cutter

- Details

- Category: Tungsten Information

- Published on Monday, 04 March 2019 09:15

Recently, "the strongest brain" Central South University and the "shield giant" iron construction heavy industry marriage. What kind of spark will this shine? What kind of story will be created? It is bound to create an "iron-tooth steel tooth" that exerts the best performance of "Pangolin"!

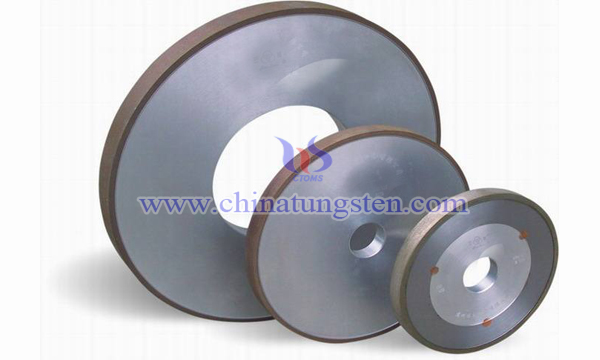

How to Make Tungsten-based Diamond Grinding Wheel

- Details

- Category: Tungsten Information

- Published on Thursday, 28 February 2019 22:37

Diamond grinding wheels are widely used in the efficient processing of low iron content metals and hard and brittle materials, such as cemented carbides, high alumina ceramics, optical glass, agate gems, semiconductor materials and stone materials.

sales@chinatungsten.com

sales@chinatungsten.com