Laser Electroplating of Nickel Phosphorus Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 23:22

Tungsten carbide particles have a series of advantages, such as chemical stability, high hardness, almost comparable to the hardness of diamond, and extremely high wear resistance. The bonding strength between deposited tungsten carbide particles and Ni-P coatings will affect the performance of the composite coatings. Therefore, improving the bonding strength between coating and matrix and the bonding between deposited tungsten carbide particles and nickel phosphorus cells and avoiding the falling off of deposited particles become the key to ensure the effectiveness of composite coating.

How to Improve the Particle Size of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 23:12

Tungsten powder is widely used in cemented carbide, tungsten products, chemical industry and steel industry. Tungsten powder is used as raw material for cemented carbide products and other tungsten products. Its particle size and size distribution have an important impact on product performance.

Reverse Thinking to Obtain Gypsum from Scheelite Slag

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 23:01

Because tungsten can form soluble heteropoly acid (such as [PW12O40]3-) with impurities such as phosphorus, arsenic and silicon at the ratio of 1:6 to 1:12, a small amount of phosphorus can cause a large amount of tungsten dispersion and loss in the process of hydrochloric acid decomposition, so hydrochloric acid decomposition process mainly deals with high-grade Scheelite Concentrate (requiring low impurities such as phosphorus and arsenic).

Tungsten Copper Board File

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:54

Tungsten copper board file is a file fitter filing of tool steel, steel file sub-flat, round, square, angular, five and a half, flat to flat file also challenge the filing, circle is round file, square is square file, triangular file angle, half semicircle filing, the board filing can also be called flat file.

Tungsten Copper Support Plate

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:52

Tungsten copper support plate means it is used as a key foundation dedicated integrated circuit card module encapsulation material, primarily protects the chip and the role of integrated circuit chips and external interface as in the form of the strip, the surface will be gold-plated gold yellow.

Tungsten Copper Labtech

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:50

Tungsten copper labtech combines the advantages of tungsten and copper, because of its high thermal conductivity so that electric panels can heat rapidly. Compared to other metal materials, tungsten copper with superior thermal performance, long life, can greatly reduce costs.

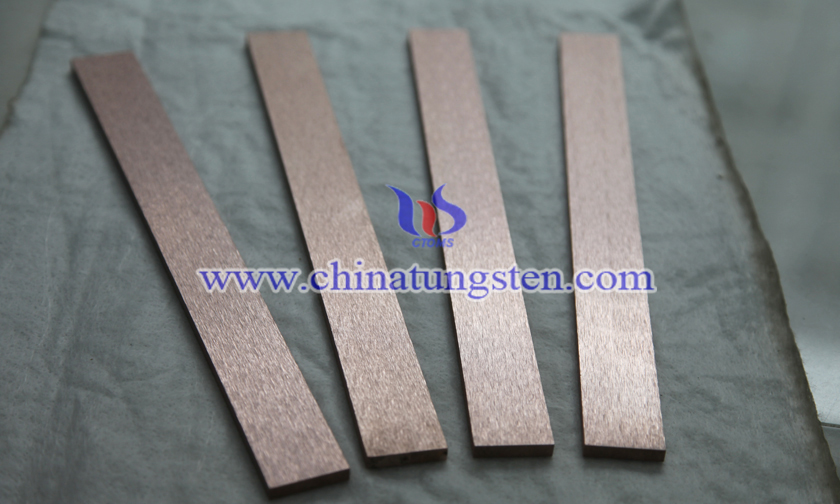

15×100×200mm Tungsten Copper Plate

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:45

15×100×200mm tungsten copper plate with 8mm thickness, width is 100mm, and length is 200mm, general tolerance of thickness is ±0.2mm, length and width tolerance is 0 to +2mm. It can be applied to heavy-duty sliding friction, high-speed and moving solid seals. Various instruments require non-magnetic, low expansion, high elastic modulus, shielding and other special requirements.

10×100×200mm Tungsten Copper Plate

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:43

10×100×200mm tungsten copper plate with 8mm thickness, width is 100mm, and length is 200mm, general tolerance of thickness is ±0.2mm, length and width tolerance is 0 to +2mm. An important use of high-density tungsten copper plate is as high-temperature components such as gas rudders, nozzles, throat linings, and nose cones that are ablated and washed by high-temperature, high-speed airflow such as rockets and missiles.

8×100×200mm Tungsten Copper Plate

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:42

8×100×200mm tungsten copper plate with 8mm thickness, width is 100mm, and length is 200mm, general tolerance of thickness is ±0.2mm, length and width tolerance is 0 to +2mm. Which with excellent electrical and thermal conductivity, uniform microstructure, high temperature resistance, high strength, arc erosion resistance and high density.

5×100×200mm Tungsten Copper Plate

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 February 2019 14:40

5×100×200mm tungsten copper plate with 5mm thickness, width is 100mm, and length is 200mm, general tolerance of thickness is ±0.2mm, length and width tolerance is 0 to +2mm. With excellent electrical and thermal conductivity, uniform microstructure, high temperature resistance, high strength, arc erosion resistance and high density.

sales@chinatungsten.com

sales@chinatungsten.com