Tungsten Carbide-Carbon Nanofibers Composite Film as a New Electrode Material

- Details

- Category: Tungsten Information

- Published on Thursday, 28 March 2019 22:47

Tungsten carbide is a typical transition metal carbide, which belongs to hexagonal system. Tungsten carbide has good conductivity, and nano-sized tungsten carbide has good potential to replace noble metals as catalysts for hydrogen evolution. Therefore, it has attracted wide attention in the field of catalytic hydrogen evolution.

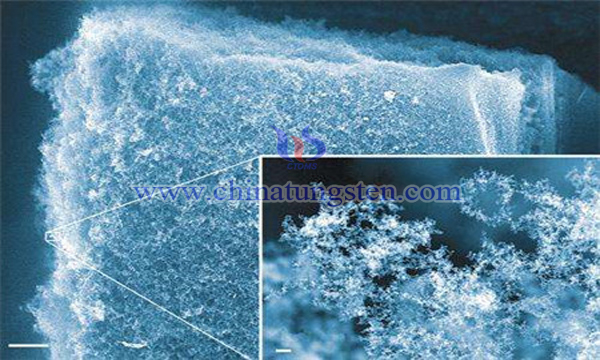

Electrospinning is a simple and effective technology for the preparation of carbon nanofibers. Polymer solution is spinned by high voltage electrostatic spinning, followed by Pre-oxidation and high temperature carbonization to prepare carbon nanofibers with three-dimensional porous structure, high specific surface area and high conductivity. Some scholars have proposed a preparation method of tungsten carbide-carbon nanofibers composite membranes. The experimental process is as follows:

(1)0.75g ammonium tetrathiotungstate and 0.5g polyacrylonitrile powder were added into 5mL N, N-dimethylformamide solvent and stirred continuously to obtain homogeneous viscous dispersion.

(2)The electrospinning process parameters of the obtained dispersion solution are as follows: the electrostatic field voltage is 20 kV, the spinning speed is 0.1 mm min-1, the receiving distance is 20 cm, and the ammonium tetrathiotungstate/polyacrylonitrile spinning film is obtained.

(3)Ammonium tetrathiotungstate/polyacrylonitrile composite membranes were prepared by pre-oxidation of the obtained spinning membranes in air atmosphere, with pre-oxidation temperature of 250 C, heating rate of 2 min-1 and pre-oxidation constant temperature time of 2 h.

(4)The obtained pre-oxidized ammonium tetrathiotungstate/polyacrylonitrile composite film was carbonized at high temperature in argon-hydrogen atmosphere in one step. The heat treatment temperature was 700 C, the heating rate was 5 C min-1, and the constant temperature time was 5 h. The tungsten carbide-embedded carbon nanofibers composite film was prepared by in-situ calcination method, which was recorded as W2C/CNF-1.

In the electrochemical test, the carbon nanofiber composite was used as the positive electrode and lithium sheet as the negative electrode to assemble the buckled semi-battery. The capacitance of the carbon nanofiber composite was studied by the charge-discharge curve of the battery. It can be seen from the charge-discharge curves that the specific capacity of the WC-embedded carbon nanofibers composite membrane assembly battery is significantly increased when the current density is 0.1Ag compared with that of pure carbon nanofibers. It can be used as an ideal flexible self-supporting electrode material for new energy devices such as lithium ion batteries and supercapacitors.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com