Carbon Nanotubes and Tungsten Carbide Composites

- Details

- Category: Tungsten Information

- Published on Thursday, 28 March 2019 22:41

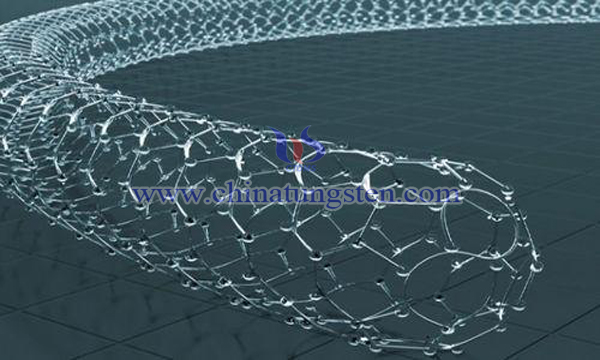

In recent years, the research on mechanical properties of high performance composite cemented carbides has become one of the frontier topics in the field of cemented carbides. Carbon nanotubes are one-dimensional nanomaterials composed of stable C_C covalent bonds, which have super comprehensive mechanical properties.

The theoretical study shows that the average Young's modulus of multi-walled carbon nanotubes is 1.8 TPa and the average bending strength is 14.2 GPa. The tensile strength of carbon nanotubes is 100 times that of steel, and the specific gravity of carbon nanotubes is only one sixth of that of steel. The thermal conductivity of carbon nanotubes is similar to that of diamond and its conductivity is higher than that of copper, so it is considered to be an ideal ultimate reinforcing material with super-strength composites. To this end, the researchers used Hot-pressing Sintering Technology to prepare carbon nanotubes and tungsten carbide composites. The specific steps are as follows:

(1)Tungsten carbide and alumina powder were obtained by mechanical metallurgy. Carbide powder and alumina powder were mixed with a weight ratio of 9:1, and then mixed powder and grinding balls with diameter of 10 mm were put into the ball mill tank according to the ratio of 10:1. High purity argon gas was added to protect the ball during the ball milling process, and the milling time was 50 hours.

(2)Tungsten carbide and alumina powder were mixed with single-walled carbon nanotubes by ball milling. When tungsten carbide, alumina and carbon nanotubes were put into the ball mill, carbon nanotubes accounted for 0.1 wt% of the total mixed powder. High purity argon was introduced to protect the ball milling process, and the milling time was 5 hours.

(3)The mixed powder obtained in the second step is put into the vacuum furnace, and the vacuum degree is kept at 1.3 *10.

The obtained tungsten carbide-alumina and tungsten carbide-alumina composite cemented carbides containing carbon nanotubes were tested as follows: Vickers hardness tester was used to test the hardness of the samples. Vickers hardness values of tungsten carbide, alumina and tungsten carbide, alumina and carbon nanotubes were measured by Vickers hardness tester. The Vickers hardness values of tungsten carbide-alumina composite cemented carbide and tungsten carbide-alumina-carbon nanotube composite cemented carbide are 16.55 GPa and 20.76 GPa respectively. It is confirmed that the addition of carbon nanotubes can improve the mechanical and Tribological Properties of the composite, improve its friction reduction and greatly improve the hardness of the cemented carbide.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com