Near Spherical Tungsten Powder Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 March 2019 23:02

Tungsten metal has a series of excellent properties such as high hardness, high strength, low vapor pressure, good corrosion resistance and high temperature corrosion resistance. The tungsten porous body made from it has excellent dimensional stability and durable life, and has been widely used in the fields of electronics, aviation, weapons and other applications.

With the development of electronics and aeronautics, the requirement of spherical dense and fine morphology and structure for tungsten materials has been put forward in many scientific and technological fields. Therefore, the research and development of high-performance spherical tungsten powder is of great significance to give full play to China's superior resources and promote the development of China's material industry. However, due to raw materials (such as regenerated tungsten) or process reasons, the control of the production of spherical tungsten powder is not satisfactory, and the production efficiency needs to be improved.

Some scholars believe that near-spherical tungsten powder also has excellent properties of spherical tungsten powder, and its preparation process and process operation are simpler, which can greatly reduce the cost. For example, the following methods can be used:

A.Industrial polygonal tungsten powder with an average particle size of 7.5 um was dried to 0.1% water content at 100 C.

B.The dried tungsten powder was oxidized at 450 for 120 min, and then cooled to room temperature when the oxidation weight gain was 8g/100g.

C.The powder treated by step B was added to NaOH solution with a concentration of 3 mol/L. The ratio of powder to solution was 1 g:5 ml and the reaction temperature was 70 C. Then the powder was stationary until the solution was transparent and the color of precipitation was the same as that of the original tungsten powder, and the supernatant was removed.

D.Wash the Alkali-Washed powder of step C twice with deionized water. The ratio of powder to deionized water is 1g/25ml. Then wash with alcohol. The ratio of powder to alcohol is 1g/25ml.

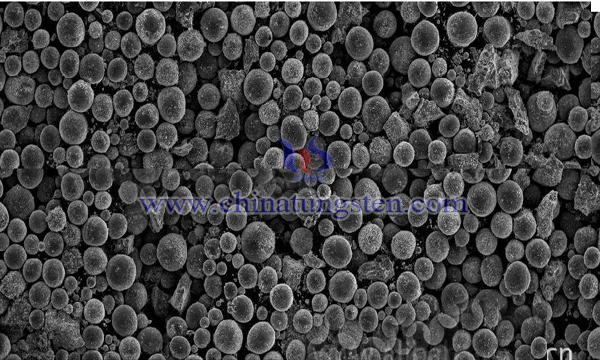

E.The powder cleaned by D step was dried under argon protection at 50 C until the moisture content was reduced to 0.5%. Finally, the nearly spherical tungsten powder with an average particle size of 3 um was prepared.

Tungsten powder is dried and then oxidized. The oxidation rate of tungsten powder in the oxidation process is obviously higher than that of the flat surface due to the large specific surface area at the sharp corners and edges of tungsten powder. After washing the sharp corners and edges of the protruding parts (sharp corners) with alkali solution, the near spherical particles with smoother surface than the original tungsten powder particles are formed. The near-spherical tungsten powder has the advantages of good uniformity in shape distribution, simple process and low production cost, and is suitable for industrial production.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com