Optimal Design of Tungsten Crucible in Crystal Growth Furnace

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:33

Tungsten crucible plays an important role in the process of crystal growth, such as bearing molten raw materials, high-temperature heat transfer and environmental isolation, and its reasonable design directly affects the quality, yield and stability of the whole process. Therefore, it is of great significance to carry out the optimal design of the crucible according to the special working conditions of the crystal growth furnace.

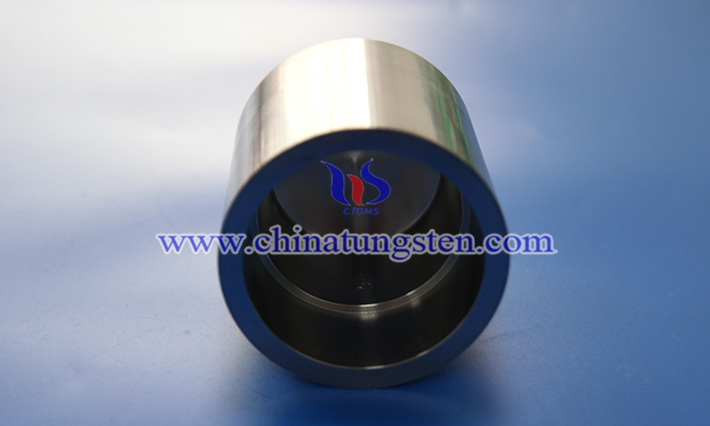

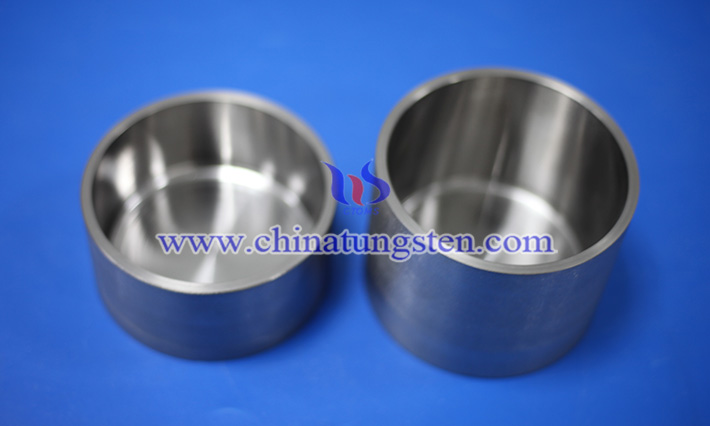

First of all, the geometry of the crucible needs to be designed with the melt flow and temperature distribution in mind. Reasonable crucible shape can not only ensure that the melt is heated evenly, reduce the temperature gradient, and prevent crystal defects caused by local overheating, but also effectively control the flow state of the melt and avoid impurity entrainment and crystallization interface disturbance. Common designs include a cylindrical or tapered structure with a slightly sloping inner wall, which helps to create a stable thermal convection pattern and promote uniform crystal growth. In addition, precise control of the wall thickness and size of the crucible is also key to the design, as a thin wall thickness may lead to rapid heat loss, and a wall thickness that is too thick will affect the heat conduction efficiency and thermal field control.

Secondly, the material selection and process optimization of crucibles are crucial to the performance performance. High-purity tungsten powder and advanced powder metallurgy process ensure that the crucible is dense and non-porous, with a uniform structure, thereby improving thermal conductivity and thermal shock resistance. CNC precision turning and polishing technology is used in the processing process, which can achieve smooth inner wall, reduce the uneven contact between the melt and the crucible interface, and reduce the risk of impurity adsorption. In terms of surface treatment, some processes also apply a protective layer of molybdenum or ceramic to the inner wall of the crucible to enhance corrosion resistance and extend service life.

Third, the thermal management design of the crucible is central to optimizing the crystal growth process. During crystal growth, the precise control of temperature directly determines the quality and defect rate of the crystal. The high thermal conductivity of the crucible should be considered in the design, combined with the heater layout and cooling system, to optimize the heat flow path and achieve a stable and uniform temperature field. Thermal field simulation with finite element analysis software can help engineers predict the temperature distribution and thermal stress under different design schemes, and guide the optimization and adjustment of crucible structure and process parameters.

In addition, the mechanical strength and durability design of tungsten crucible cannot be ignored. During the operation of the crystal growth furnace, the crucible needs to withstand the stress caused by high-temperature thermal expansion and thermal cycling. The thermal expansion coefficient and fatigue resistance of tungsten need to be fully considered in the design to avoid cracks caused by excessive temperature gradient. By selecting the appropriate crucible size ratio and optimizing the support structure, the stress concentration can be effectively dispersed and the service life and stability of the crucible can be improved.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com