Ultrafine Spherical Tungsten Powder Preparation by RF Plasma Spheroidization

- Details

- Category: Tungsten Information

- Published on Friday, 29 March 2019 23:06

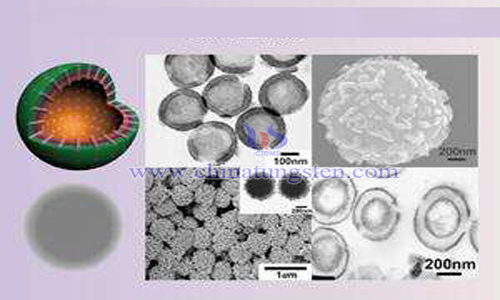

At present, the preparation of spherical tungsten powder at home and abroad mainly adopts radio frequency plasma spheroidization method. The spherical tungsten powder prepared by this method has high sphericity. However, due to the agglomeration of tungsten powder, the spherical tungsten powder grows up after spheroidization, and it is difficult to produce spherical tungsten powder with particle size less than 10 micrometers. Therefore, how to obtain spherical tungsten powder with uniform particle size distribution has been paid more and more attention by scientists and technicians.

In order to prepare spherical tungsten powder with high sphericity, smooth surface, good dispersion and uniform particle size, some technicians upgraded and improved the RF plasma spheroidization method. The process includes:

1.Air dispersion and classification

The powder with good dispersion and uniform particle size distribution can be obtained by feeding the raw material powder into air grinding. The separating wheel speed of airflow mill is 2500-7000 rpm, the pressure of grinding chamber is 0.1 MPa-1 MPa, and the feeding rate is 0.1-20 kg/h. The parameters depend on the original powder.

2.Radio frequency plasma spheroidization

The powder received in step 1 is spheroidized by radio frequency plasma spheroidizing device. The main technological parameters are: power 50~100KW, argon working gas flow 20~60slpm, argon protective gas flow 50~100slpm, system negative pressure 800~1500mm water column, powder feeding gas flow 2~10slpm, powder feeding rate 10~50g/min.

The improved process combines gas impingement dispersion with radio frequency plasma spheroidization to solve the problem that ultrafine tungsten powder is easy to agglomerate and make the spheroidized powder grow up. Ultrafine spherical tungsten powder with particle size less than 10 micron, spheroidization rate of 100%, smooth surface, uniform particle size distribution and good dispersion is prepared.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com