Tungsten Gold-Plated Coin for Adult Ceremony

- Details

- Category: Tungsten Information

- Published on Monday, 21 March 2016 11:53

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Bar for Christmas

- Details

- Category: Tungsten Information

- Published on Monday, 21 March 2016 11:48

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coin for Halloween

- Details

- Category: Tungsten Information

- Published on Monday, 21 March 2016 11:44

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

SCR Denitration Catalyst Raw Material – Tungsten Trioxide 2/2

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 18:56

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

SCR Denitration Catalyst Raw Material – Tungsten Trioxide 1/2

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 18:51

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What Are Tungsten Bronzes II

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 17:27

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What Are Tungsten Bronzes I

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 17:24

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Processing Optimization (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 16:38

However, high cost of equipment needed for hot isostatic pressing, productivity is relatively low, so another low pressure - hot isostatic pressing (LP-HIP) emerges. It will degrease and be densified in the furnace once completed, combined with vacuum sintering at relatively low temperatures and pressures, argon Ar as a medium hot isostatic pressing. This approach simplifies the process, saving energy consumption, to avoid the occurrence of the workpiece is difficult to control the carbon content in the production finally direct contact with air, which greatly eliminates the tooth carbide ball inside the residual porosity, grain refinement, effective by eliminating the hot isostatic pressing coarse-grained, cobalt pool and other defects, significantly improves the mechanical properties of tungsten carbide buttons.

The quenching - aging main principle is Co binder phase can occur under certain conditions allotropic transformation, which was at room temperature HCP ε-Co, plasticity is poor, and when the temperature raises it can be converted face-centered cubic structure α-Co with good plasticity. In the quenching process, Co binder phase transition occurs rapidly cooled to room temperature and dissolved, so that α-Co is preserved. After aging, tungsten carbide buttons can be made in the supersaturated vacancies move grain boundaries or dislocations, etc. disappear, thereby reducing the lattice distortion, high stress relaxation area, making the overall flexural strength has been significantly improved. Currently, some quenching – aging treatments have been applied in production, such as vacuum oil quenching - natural aging, vacuums gas quenching – tempering and so on. They can be based maintaining tungsten carbide buttons on the other properties, and improve the hardness and toughness of buttons.

Conventional tungsten carbide buttons are round-shaped and bullet-shaped. In the process of drilling, round-shaped buttons will be easily passivated, and the bullet-shaped has shrill crown, which will be easily broken caused by insufficient strength of the matrix in some high impact loads or hard rock crushing conditions. Therefore, to improve tungsten carbide button shape has also become one of the research directions of researchers and scholars. Resistant carbide button is composed of a ball cap and approximate cone shape. In the process of breaking rocks in spherical cap shape be spherical die broken, approximate cone crusher is dovetail die, the two complement each other to get a good rock-breaking effect. It has higher drilling rate, excellent impact resistance, especially in some deep and long distance drilling, it has a good self-sharpening and does not need to be dragged, which remarkably improves the drilling efficiency.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Processing Optimization (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 16:36

Tungsten carbide button is mainly composed of tungsten carbide (WC) + cobalt (Co), WC is hard phase, and Co is soft phase (binder). They complement each other so that tungsten carbide buttons have better hardness, wear resistance and toughness than other materials, which accelerates the drilling, improves the efficiency and extends the service life of tools. In order to improve overall properties of tungsten carbide buttons, we can optimize from two sides, one is to optimize the raw materials of tungsten carbide itself (grain refinement, structure optimization and trace elements adding), another is to optimize the processing, which includes LP-HIP (Low Pressure – Hot Isostatic Pressing), quenching-aging treatment and shape of button optimization, etc.

After sintering, tungsten carbide button will leave some porosity and internal defects, which decreases the toughness and strength of tungsten carbide buttons. Through many experiments, HIP successfully applied in tungsten carbide buttons production. HIP (Hot Isostatic Pressing) refers to place the products in a closed container, the pressure is applied equally to each of the products, while applying heat, under the action of high temperature and pressure, and make the products densified. In addition, HIP can also be directly involved in the powder molding, powder put into the sheath (mold), wrap can be used metal or ceramic production (low-carbon steel, Ni, Mo, glass, etc.), and then use the nitrogen N2, or Ar gas atmosphere, the powder is directly heated and pressurized sintering the powder metallurgy process.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

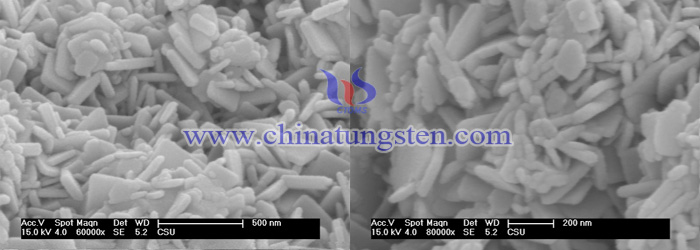

Tungsten Oxide Crystalline Form Affects Tungsten Carbide Property

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 16:30

Under certain conditions the six-phase tungsten oxide(h-WO3)can exist in stable form. When annealing temperature exceeds 400℃, it can turns into monoclinic system(γ-WO3). Nano tungsten oxide applied in electric and optical field is different from tungsten oxide bulk. The main differences are phase transition temperature drops evidently, so sometimes orthorhombic tungsten oxide(β-WO3)appears and is stable under room temperature.

Chemical stoichiometric number of tungsten oxide seems simple, its phase transition and structure change is complex. The ideal tungsten oxide is octahedron, W6+ exists in the center part of it. O2 as anion distribute in the other eight edges. Actually, W6+ often deviates from the center part, the whole structure turns into tetragonal crystal(α-WO3), temperature range is T>740℃. For orthorhombic system, 740℃>T>330℃; monoclinic system: 330℃>T>17℃ and triclinic system: 17℃>T>-43℃.

Below are SEM graphs of tungsten oxide, testing equipments are: ICP-AES Spectrograph, X-ray Powder Diffractometer, TSM-6360 LV scanning electron microscope, MICROPLUS laser diffraction particle size analyzer.

In a word, tungsten oxide has various crystalline forms, its transition can affect its property, tungsten oxide crystalline form can largely affects tungsten carbide property. Due to this factor, tungsten oxide can be applied in many fields because of its multi-properties.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com