Applications of Tungsten-Nickel-Iron Alloy in Welding Electrodes

- Details

- Category: Tungsten Information

- Published on Thursday, 17 July 2025 15:19

Tungsten-nickel-iron alloy, with its unique physical and mechanical properties, demonstrates significant applications value in the field of welding electrodes. When used to manufacture welding electrodes, the high tungsten content (typically over 90%) is the core source of its advantages. Tungsten’s melting point, as high as 3422°C, far exceeds that of most metal materials, enabling the electrode to maintain a stable form in the high-temperature arc environment and preventing excessive wear due to melting. This is crucial for ensuring the continuity of the welding process. The addition of nickel and iron effectively mitigates the brittleness of pure tungsten, providing the electrode with a certain degree of plasticity and toughness, making it less prone to cracking during processing, installation, and use, while also enhancing its electrical conductivity to ensure stable arc generation and energy transfer.

Applications of Tungsten-Nickel-Iron Alloy in the Medical Field

- Details

- Category: Tungsten Information

- Published on Thursday, 17 July 2025 15:16

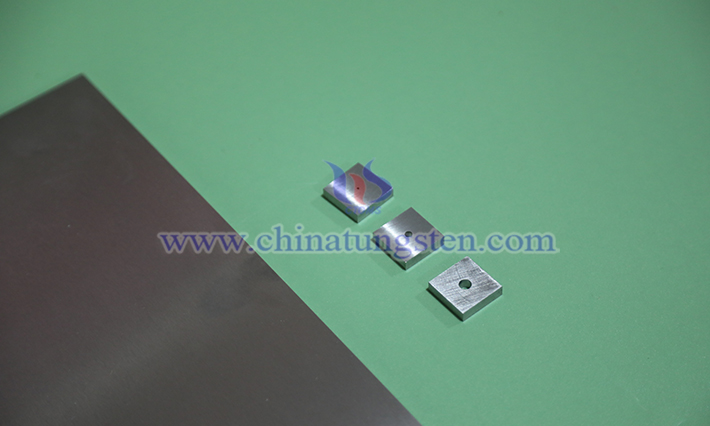

The applications of tungsten-nickel-iron alloy as a shielding material in the medical field stems from its unique physical properties, such as high density, good chemical stability, and excellent radiation shielding capabilities. With a density typically ranging from 16.5 to 18.75 g/cm³, its ability to attenuate X-rays, γ-rays, and other radiation is comparable to traditional lead shielding materials. Moreover, it is less prone to fracturing or deforming due to impacts or vibrations, giving it a clear advantage in medical radiation protection scenarios.

Impact of Carbon on the Hardness of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Thursday, 17 July 2025 15:13

Carbon plays a critical role in regulating the microstructure and mechanical properties of tungsten-nickel-iron alloys, with its influence on alloy hardness primarily achieved through altering the microstructure, forming carbides, and modulating interface bonding states.

Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 July 2025 19:00

As an important product of the inorganic metal tungsten, tungsten alloy has an extremely wide range of applications, including electronics, automotive, defense, military, aerospace, aviation, maritime, optoelectronics, and medical fields.

Impurity Elements in Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 July 2025 17:36

Tungsten-nickel-iron alloy, a crucial tungsten-based alloy, uses tungsten as its matrix, with tungsten content typically ranging from 90% to 98%, forming the alloy’s foundational structure. Nickel and iron, as primary additive elements, play critical roles, with common nickel-to-iron ratios of 7:3 or 1:1.

Unlocking the Performance Secrets of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 July 2025 17:32

In the vast starry sky of modern industry, tungsten-nickel-iron alloy shines like a brilliant star, occupying a pivotal position in numerous critical fields due to its excellent mechanical, chemical, and thermal properties. From precision components in aerospace to core equipment in defense and military applications, from high-end medical instruments to tools in industrial manufacturing, its presence is ubiquitous. This alloy is not a mere amalgamation of inpidual elements but a sophisticated material born from the synergistic interplay of tungsten, nickel, and iron. It is the critical roles played by these three elements and their remarkable interactions that endow tungsten-nickel-iron alloy with its exceptional comprehensive performance. Today, let us delve into the vital roles of tungsten, nickel, and iron in this alloy, unlocking the secrets behind its material marvel.

Applications of Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 14 July 2025 15:36

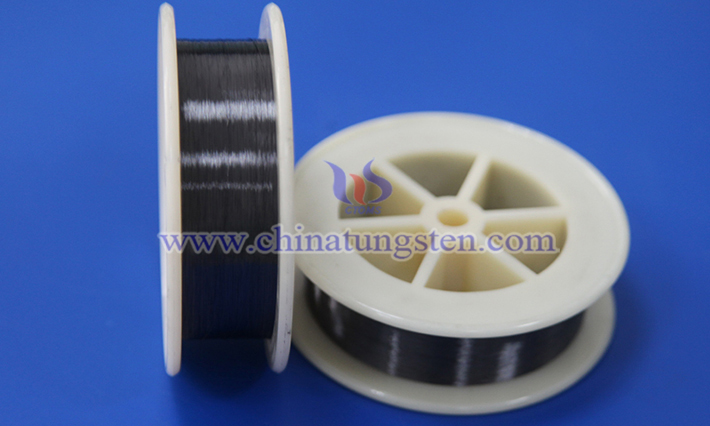

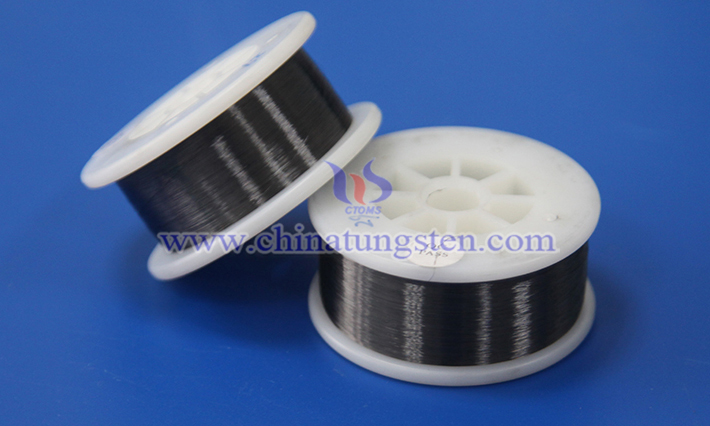

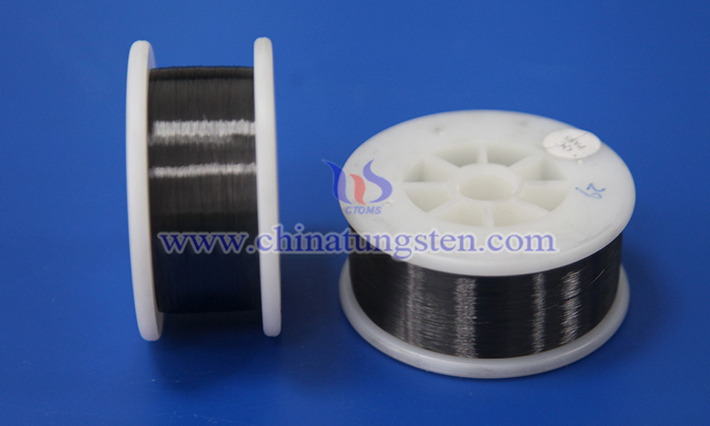

The high strength, high temperature resistance, corrosion resistance and electrical and thermal conductivity of tungsten wire make it irreplaceable in scenarios that require high reliability and durability. The following is an introduction to its main applications:

Advantages and Disadvantages of Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 14 July 2025 15:33

As a common material, tungsten wire is widely used to make filaments and other high-temperature components, especially in light bulbs and electronic devices. The following are the advantages and disadvantages of tungsten wire:

Characteristics of Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 14 July 2025 15:31

The main characteristics of tungsten wire are as follows:

High Melting Point: Tungsten has an extremely high melting point of about 3422°C, the highest of all metals, and is suitable for use in high temperature environments, such as incandescent bulbs and electron tubes.

What is Cleaned Tungsten Wire?

- Details

- Category: Tungsten Information

- Published on Monday, 14 July 2025 15:28

Cleaned Tungsten Wire refers to a filament made of tungsten metal. It is widely used in various industrial and scientific fields because of its high melting point (about 3422°C), high strength and good conductivity. The surface of cleaned tungsten wire is generally treated with alkali washing, showing a silver-gray metallic luster, so it is called "white tungsten wire".

sales@chinatungsten.com

sales@chinatungsten.com