Thermal Conductivity Analysis of Tungsten Crucibles

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:14

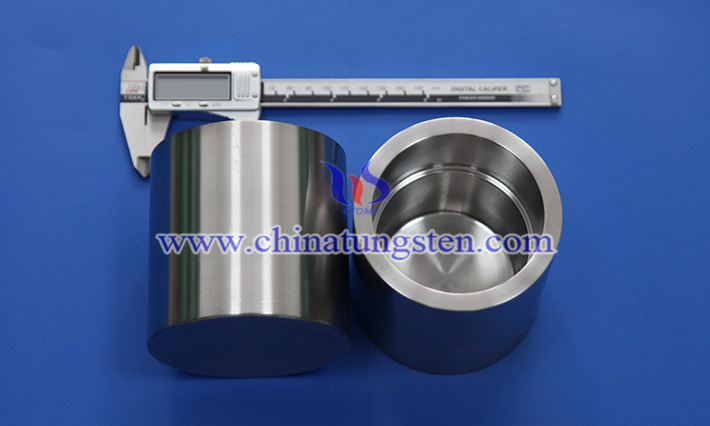

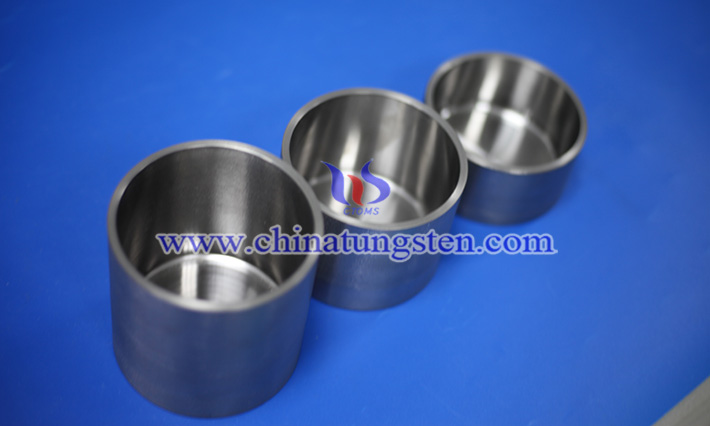

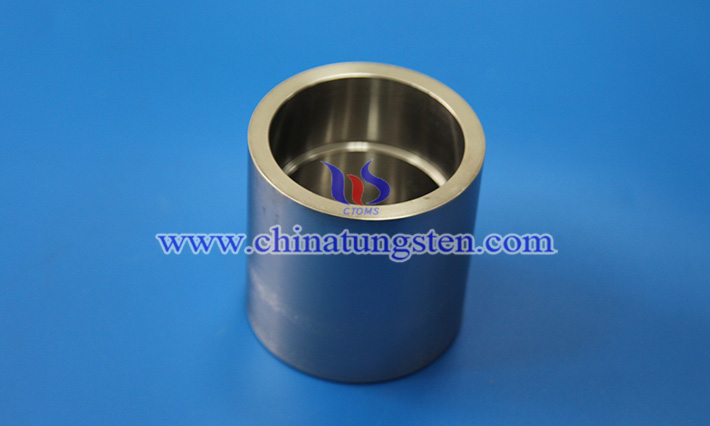

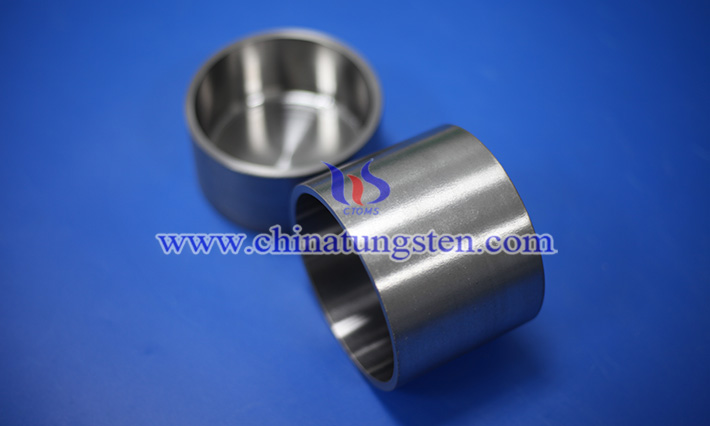

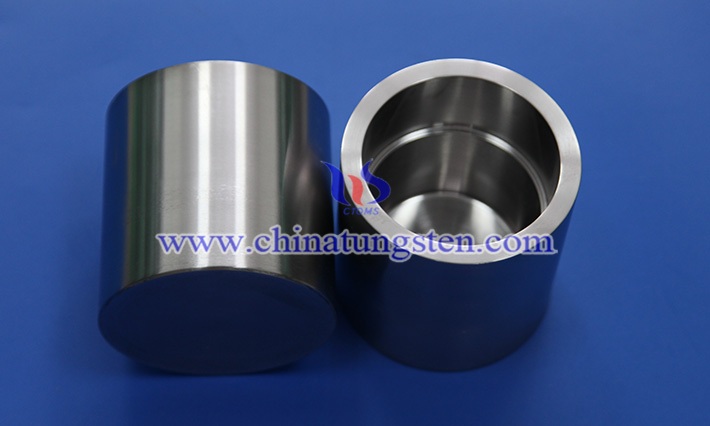

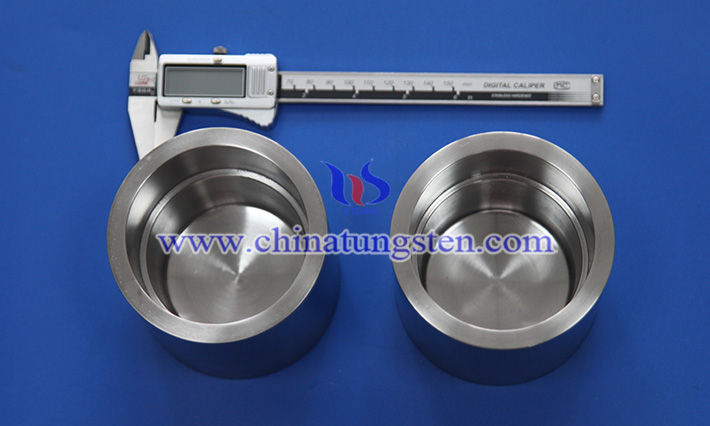

Tungsten crucibles are widely used in sapphire crystal growth, rare metal smelting, high-temperature material testing and other fields due to their excellent high-temperature stability and corrosion resistance.

Potential Applications of Tungsten Crucibles in the Nuclear Industry

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:11

Among many components, tungsten crucibles are attracting more and more attention from research institutions and industries due to their excellent heat resistance, corrosion resistance, radiation resistance and other characteristics, and its potential applications in nuclear fuel processing, high-level radioactive waste treatment and next-generation nuclear energy systems are worthy of in-depth discussion.

Chemical Stability Studies of Tungsten Crucibles

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:07

Tungsten material is widely used in high-temperature thermal field, vacuum smelting, crystal growth and other cutting-edge scientific and technological fields. In these applications, tungsten crucibles have become important vessels for carrying molten metals or chemical reactants due to their advantages of high temperature resistance, high thermal conductivity, and non-deformation.

The Powder Metallurgy Technology for Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:04

Tungsten is widely used in industrial scenarios such as high-temperature metallurgy, crystal growth, and vacuum smelting due to its ultra-high melting point, excellent high-temperature resistance and chemical stability. Especially in the preparation of molybdenum, titanium, rare earth and other active metal materials, tungsten crucible has become an ideal container material because it is not easy to react with the melt and can withstand extreme thermal stress.

Failure Analysis of Tungsten Crucible in High-Temperature Experiments

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:01

Due to its extremely high melting point, excellent high-temperature mechanical properties and good chemical stability, tungsten crucible is widely used in high-temperature experiments in aerospace, metallurgy, materials science and other fields, especially in crystal growth, metal smelting and rare element extraction, etc., which plays a key role. However, in the actual use process, tungsten crucibles are not "indestructible", and will still fail in different forms due to a variety of complex factors.

What Are the Surface Treatment Technologies of Tungsten Crucibles?

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 10:58

As a metal with a high melting point, tungsten is widely used in high-temperature smelting, single crystal growth, vacuum evaporation and other industrial fields due to its excellent thermal stability, corrosion resistance and high strength.

What Is the Wear Resistance of Tungsten Crucible?

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 10:51

Tungsten crucibles play an important role in high-temperature metallurgy, crystal growth, vacuum smelting and other fields, and have long been known for their excellent high temperature resistance and good chemical stability.

Tungsten-Nickel-Copper Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 18:53

In the vast field of materials science, tungsten-nickel-copper alloy (W-Ni-Cu) shines like a brilliant star, exuding unique charm. As a high-performance material with tungsten as the matrix and alloying elements such as nickel and copper, it is known as the "versatile player" in the industrial field, playing an indispensable role in many key industries. From the high-tech aerospace sector to the manufacturing of daily electronic devices, its presence is ubiquitous. Let us now delve into the wonderful world of tungsten-nickel-copper alloy, exploring its composition, unique properties, and extensive applications.

Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 18:47

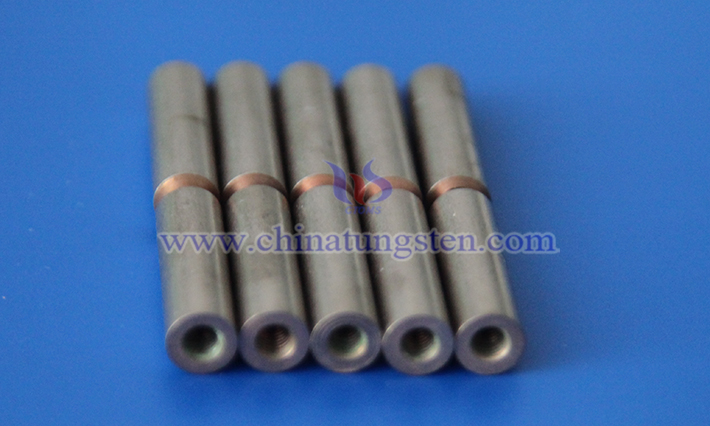

Tungsten-nickel-iron alloy is an important tungsten-based high-density alloy. By definition, it is an alloy composed of adding nickel and iron to metallic tungsten, with the nickel-iron ratio typically maintained at 7:3 or 1:1. With excellent comprehensive properties, this type of alloy is widely applied and has become the main category of tungsten-based alloys with large usage at present.

Thermal Stability of Tungsten Wire in Heating Glass Equipment

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 17:13

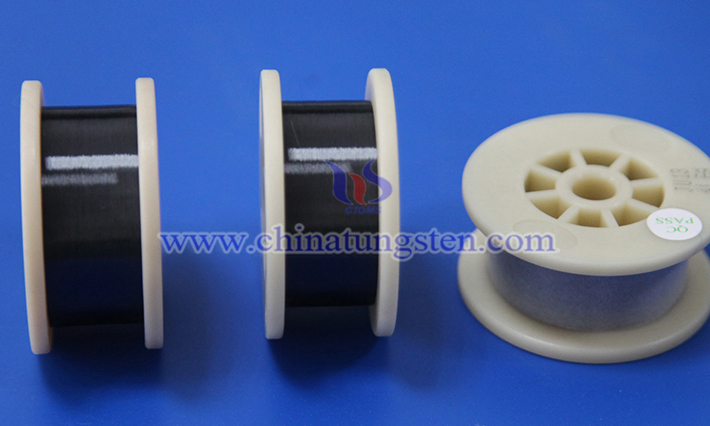

Tungsten wire exhibits excellent thermal stability in heating glass equipment due to its ultra-high melting point, low vapor pressure, excellent high temperature strength, good creep resistance (especially non-drooping tungsten wire) and low thermal expansion coefficient, making it an ideal choice for high temperature heating elements.

sales@chinatungsten.com

sales@chinatungsten.com