Stability of Tungsten Crucible in a High-Temperature Vacuum Environment

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:30

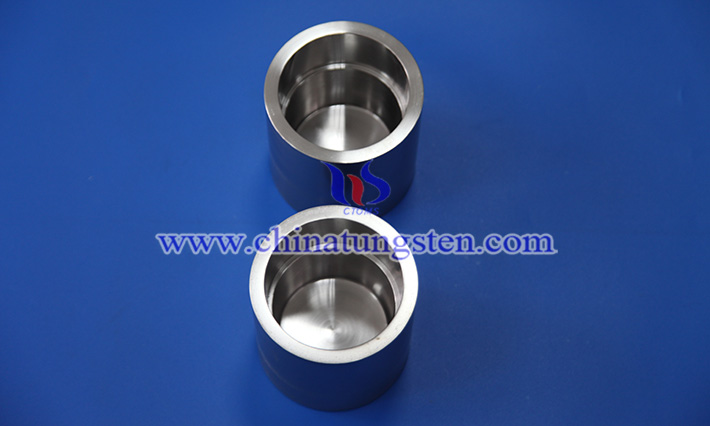

Tungsten crucible is widely used in high-temperature vacuum processes such as crystal growth, rare metal smelting and vacuum evaporation due to its high temperature resistance, thermal shock resistance and strong chemical inertness.

This paper focuses on the stability performance and influencing factors of crucibles in high-temperature vacuum environment, aiming to provide theoretical support and practical reference for the design and operation of related high-temperature equipment.

First of all, the chemical stability of W crucible in vacuum is significantly better than that of atmospheric air. Under vacuum conditions, the oxygen content is very low, and the tungsten surface will not undergo oxidation reaction, which avoids the structural damage caused by the tungsten trioxide (WO₃) layer and its volatilization that are easy to form at high temperatures in the air. This allows crucibles to withstand high temperatures of more than 2000°C for a long time without significant chemical corrosion, ensuring the structural integrity and service life of the crucible.

Secondly, the W crucible exhibits good thermal stability and thermal shock stability in a high-temperature vacuum. Tungsten has a low coefficient of thermal expansion and excellent thermal conductivity, which can transfer heat quickly and uniformly, reducing local overheating and thermal stress accumulation. Under the condition of vacuum and high temperature, this uniform thermal conductivity greatly reduces the generation and propagation of cracks caused by thermal stress, thereby effectively improving the thermal shock resistance of the crucible and adapting to complex thermal cycling conditions.

However, despite the excellent stability of tungsten crucibles in high-temperature vacuums, there are still some potential influencing factors. The first is the issue of evaporation losses at high temperatures. Although the melting point of tungsten is extremely high at extremely high temperatures, the surface tungsten atoms have a certain evaporation rate under high vacuum conditions, especially when the evaporation rate of tungsten is accelerated at more than 2500°C, which may lead to the gradual thinning of the crucible wall thickness, affecting the structural strength and sealing performance. Therefore, it is necessary to reasonably control the operating temperature and time during design and use to avoid long-term ultra-high temperature exposure.

Secondly, the material purity and manufacturing process of the W crucible have an important impact on its stability. The high-purity tungsten material can effectively reduce the damage of impurity elements to the lattice structure and improve the mechanical strength and thermal stability of the crucible. Inhomogeneous sintering and machining processes can lead to microcracks and holes, which can easily propagate in a high-temperature vacuum environment, shortening the crucible life. Therefore, the selection of high-quality tungsten powder, high-precision molding and precision sintering technology is the key to improving the stability of the crucible.

In addition, tungsten crucibles are often accompanied by complex atmospheres, such as trace amounts of hydrogen or other reactive gases, which may react with tungsten to form brittle compounds or hydrogen embrittlement, which can affect material properties. Therefore, the fine control of process parameters and the guarantee of atmosphere purity are also necessary conditions to ensure the stability of the crucible.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com