Homogeneous CsxWO3 Nanorod on Cancer Therapy

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 18:43

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CsxWO3 Nanorods Water Controlled-Release Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 18:32

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CsxWO3: N2 Annealing Effects on Heat Shielding Properties

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 18:25

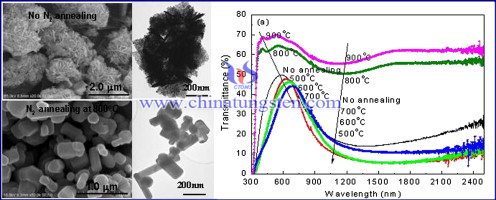

Moreover, the NIR shielding and heat insulation properties of CsxWO3 could be further improved after N2 annealing at appropriate temperature for a period of time. Particularly, the 500 °C-annealed CsxWO3 products in the N2 atmosphere showed the best NIR shielding and heat insulation properties. When the N2 annealing temperature was higher than 700 °C, the NIR shielding properties decreased again. The 800 °C-annealed samples in the N2 atmosphere showed higher visible light transmittance, however, the NIR shielding properties were lower than that of the non-annealed samples.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

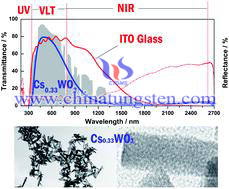

CsxWO3: N2 Annealing Effects on Near-Infrared Shielding Characteristics

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 18:13

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Properties Comparison of Different Process (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 16:37

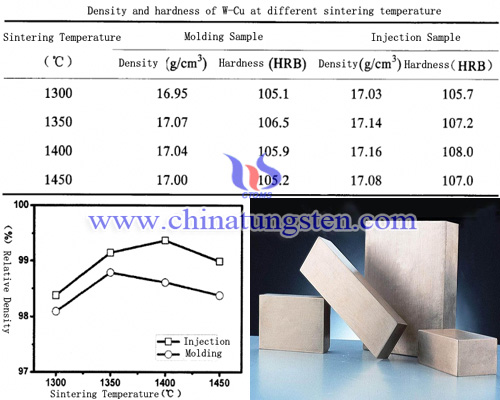

Take W-Cu tungsten copper product as a example to compare molding process with injection molding of tungsten copper material properties. W-Cu theoretical density is 17.28g / cm3, the trend of relative density and relative density with the sintering peak temperature given as follow:

As we can see from this graph above, With increasing sintering temperature, density of the obtained two processes copper tungsten composites are showing trend of increased first and then decreased. The difference is the temperature of the maximum density, the highest density of molded samples at 1350 ℃, reaches 17.16g / cm3, while the sample injected at 1400 ℃ highest density is 17.17 g / cm3. After the further increase in temperature, both the density began to decrease. This is due to the sample over-burnt, Cu phase inside of tungsten copper exudates to surface and the pores and defects left in side. Under the optimum sintering temperature, the density of injected sample reaches 99.31%, molded samples reaches 99.78%. In addition, the hardness of tungsten-copper composite material (HRB) was positively correlated to its density, the greater the density, the hardness of the respective materials is also greater.

Besides, we also compare the micro-structure of tungsten copper with different processes. The specific procedure is that milled, polished tungsten copper composite sample after etching with FeCl3 salt solution for 2 minutes, with water to clean the surface of the etching solution, then wipe the surface with alcohol cotton, and then drying, Finally placed under microscope observation of the metallurgical microstructure. By comparing the SEM photomicrographs and photographs can be found that tungsten copper molded sample of W, Cu two-phase distribution is more uniform, uniform grain size, but segregation occurs at a constant temperature inside, causing a regional copper-rich, there are some porosity. While tungsten copper sample by injection molding, W and Cu distribute uniform and does not exist W-rich phase and Cu-rich phase of the phenomenon and Cu phase forms net structure around tungsten grains.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Properties Comparison of Different Process (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 16:34

The commonly used molding technologies are molding process, extrusion molding and injection molding, wherein the molding process and injection molding process widely used in tungsten copper materials. Molding process is also known as compression molding or press molding, it is a kind of processes that put first powdered, granular or fibrous plastic into the mold cavity at a molding temperature, and then close the mold to shape and solidify. Molding process has many advantages, such as less raw material wastage, low cost of equipments, one-step forming, suitable for plate with large size. But it has long lead time, low efficiency, not suitable for products with complex structure or shape, the size is limited by the compressor.

The injection molding process here refers specifically to metal powder injection molding (MIM), it is a kind of new near net shape powder metallurgy technology that introduce from modern plastic injection molding technology into the field of powder metallurgy. The basic process is that Firstly, the solid powder with an organic binder uniformly kneaded, granulated after heating under plasticized state (~ 150 ℃) with an injection molding machine into the mold cavity solidifying-forming, and then by chemical or thermal decomposition method of forming the blank the binder removal, the final densification to give the final product. While the advantages of MIM are high density, high product consistency, a wide range of applications and can be formed smaller in size and shape of the structure of complex products. However, it has high requirements for the injection, high cost of mold design and only suitable for small batch production.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

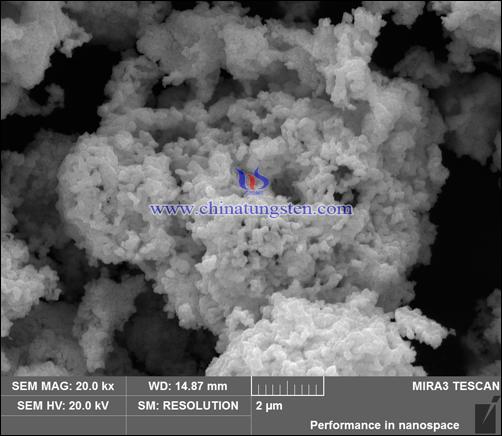

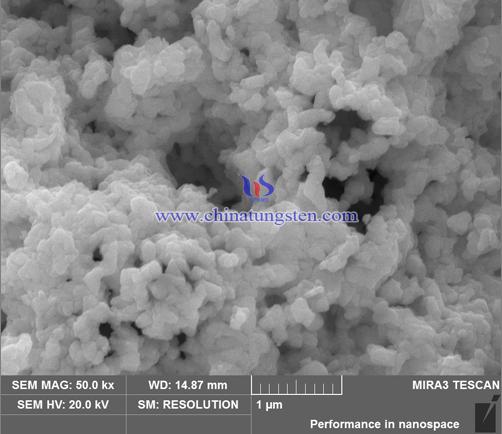

Cesium Tungsten Bronze Structure and Morphological Characterization

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 March 2016 18:03

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Wear Plate (2/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 March 2016 16:58

Tungsten carbide wear plate has high hardness, strength and excellent wear resistance, which is a kind of ideal material for glass plate. Now gate valve and S-shaped valve used more, and S-shaped valve has many advantages, such as high efficiency of reversal, no segregation of concrete, concrete pressure low loss, not easily plugged and son on. S tube floating cutting ring so fast swing plate produced both wear glasses, but also to withstand the impact force generated by S tube cutting stone, which makes the advantages of carbide are fully reflected.

Generally, the medium of S-shaped valve is concrete, which is composed of cement, water, fine coarse aggregate and other additives and the hardness index converted to a Rockwell hardness of between about HRC40-50. Therefore, the main wear patterns can be divided into two types, one is in the process of cutting ring reversal, wear plate and floating cutting ring contacts and has grain wear and erosion; the other is in the process of inhaling or pumping, the internal hole of wear plate has low stress wear and erosion.

Finally, we compare with different wear materials of wear plate, which can be specifically divided into surfacing, inlaying and integrated. Because the surface of the plate glasses usually the first began to wear also wear the most serious, except tungsten carbide, in the actual production manufacture excellent toughness, hardness and wear resistance of metal material is a certain difficulty.

So Researchers consider friction wear resistance, based on a working section surfacing wear-resistant materials, such as steel, tungsten, chromium and molybdenum, graphite electrodes, etc; inlaying materials using tungsten carbide sheet, the hardness of HRC70 or more carbide welded sheet or embedded in the ordinary steel plate, significantly increases the friction wear resistance, flexural strength was also big margin improvement, and chipping off the block does not occur, the service life reaches 30,000m2, production has become the main development direction of wear plate; integrated material includes high manganese steel, alloy tool steel, cast iron. But austenitic high manganese steel can not fully meet the requirements of wear resistance, alloy tool steel with high hardness after quenching, low cost, a shorter service life, and cast iron has lower thermal conductivity, plasticity and easily to crack.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Wear Plate (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 March 2016 16:55

With the rapid development of technology and living standard, a number of skyscrapers and infrastructure requirements are also rising. While it is essential that concrete industry with high strength and high performance involvement, which put forwards the equipments of the concrete. Concrete pump is one of the most critical parts, which consists of the pump and the delivery pipe, is a use of pressure, mechanical concrete continuously conveyed along the pipeline, mainly used in housing construction, bridge and tunnel construction. According to the types of valve, it can be divided into gate valve concrete pump and S-shaped valve concrete pump. Pumping concrete construction has many advantages, such as saving manpower and resources, improving the overall efficiency of construction, ensuring the quality of the construction and clean, which has a broad market prospect.

On the on hand, the height of building is increasing, pumping height is increasing, the pump pressure is increasing so that the requirement of tightness is increasing. On the other hand, the high strength, viscosity and low pumping property is also testing the key parts of the consumable wear resistance. Wear plate is one of the most critical wear parts, which is also known as glass plate because of the glass-like shape. Production of materials currently used are high-chromium alloy cast iron, high manganese steel, alloy tool steel, carbide, alloys and ceramics. Some wear-resistant alloy easily cracked loss and other failure modes, which will affect the pumping efficiency to a large extent.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode as TIG Cathode Requirements

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 March 2016 15:18

Tungsten electrode has high melting point, corrosion resistance, good thermal conductivity and electrical conductivity, so it is widely used in the field of welding. With the development of welding technology, tungsten electrode welding performance has gradually improved. Tungsten electrodes doped with the rare earth element to produce rare earth doped tungsten electrodes, so that the welding performance to be further developed. And common rare earth tungsten electrodes are including: cerium tungsten electrode, lanthanum tungsten electrode, zirconium tungsten electrode, and thorium tungsten electrode and so on.

Tungsten electrodes used in TIG should have following basic requirements:

1. High temperature resistance, electrodes should have good high temperature anti burning performance;

2. Electrode should have high electron emission capability;

3. Electrode should easy to arcing and can maintain stable arcing.

Pure tungsten electrode: its electron emission performance and anti-burning performance is poor, and service life is short, therefore less use in TIG welding. Pure tungsten electrode is good for broken in oxide film, so it is mainly used for AC welding of aluminum, magnesium and their alloys.

Thorium tungsten electrode: it has good electron emission properties, and the desired arc voltage is low, easy arcing and stable, with a good overall performance. However, it is radioactive, so people gradually turning to other type rare earth tungsten electrodes.

Cerium tungsten electrodes: Cerium tungsten electrodes have good thermal electron emission capability, stable arcing, heat concentration, long service life, and no radiation. At low current welding environment is the best alternative to thoriated tungsten electrode. Cerium tungsten electrodes commonly used in low current environment, mainly used for fine widget welding.

Lanthanum tungsten electrode: Lanthanum tungsten electrode has good mechanical cut property, creep resistance and high temperature performance, is the most popular electrode material. It is suitable for alternating current, and has excellent performance.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com