APT Prepares AMT- Thermal Degradation Method I

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 17:55

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Necklace for Valentine’s Day

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 17:51

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Material Optimization (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 17:30

Gradient structure optimization, also known as multi-phase alloy, its main feature is the tissue composition gradient distribution. The principle is obtained by vacuum sintering carbide containing η phase and change the distribution of Co binder phase in the carburizing atmosphere, so that different parts of the distribution of the content of different Co. That was the lowest outermost Co, known as Co-depleted layer, an intermediate for the high content of Co-rich, inner layer of WC, Co, η phase three-phase microstructure. As a result, when the gradient structure in tooth carbide ball mining or drilling operations, WC content in the outer layer of high, high hardness, wear resistance, because the intermediate layer has a high content of Co good toughness, so rock breaking load correspondingly higher. In addition, domestic researchers also study the carburizing time, carburizing temperature and carburizing atmosphere affecting the gradient structure of cemented carbide buttons that an appropriate increase in carburizing temperature is conducive to the migration to the liquid phase Co sintered body inside, different size of the sintered body, should choose different carburizing times.

Improving tungsten carbide buttons properties by adding trace elements is common in the production. Trace elements commonly added tantalum (Ta), molybdenum (Mo), phosphorus (P), a nickel (Ni), titanium carbide (TiC), tantalum carbide (of TaC) and so on. Ta and Mo as the trace elements added to the WC-Co cemented carbide system, Ta, and Mo dispersion complex carbide layer is formed between the WC particles and part of the Mo Co binder phase, which play an enhanced when worn the role of grain boundaries, thereby increasing the fracture toughness carbide button. And added Ni, P elements can be formed with the bonding phase Co Ni-Co-P alloy, Ni-P alloy, and Co-P alloys, which their eutectic temperature are significantly lower than Co itself eutectic temperature, so that the desired temperature drop obtained sintering, sintering more fully, densification is improved. TiC and TaC can improve the binder phase composition and microstructure of the grain boundaries to some extent, thereby enhancing the thermoplastic resistance, wear resistance and thermal shock resistance of tungsten carbide buttons, but it will decrease the strength of tungsten carbide buttons and increase the cost of manufacturing and using.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Material Optimization (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 17:29

Tungsten carbide button is mainly composed of tungsten carbide (WC) and cobalt (Co), which has excellent wear resistance and impact toughness. Compared with similar products, it has a higher rate of drilling. Drill bits series has passivity long life cycle, which does not wear life is about the same diameter drill bit grinding edge leader once life 5-6 times, will help save the auxiliary work, reduce manual workers and improve the efficiency. Tungsten carbide button usually used in shearer drilling, tunneling, mining machinery tools and road sweeping snow removal and road maintaining tools so that it required perfect hardness and wear resistance. In order to improve tungsten carbide button properties, it can be improved in two ways. One is to optimize the material, includes grain refinement, structure optimization and trace elements adding, another is to optimize the preparation process.

Grain refinement refers to the crystallization of ultrafine particles even nano crystallization. The studies have shown that the content of binder phase in the cemented carbide under the same circumstances, WC grain size of less than 1μm, hardness and strength carbide buttons remarkably improved. So the researchers speculate that further refinement of the WC grain size, the effect will be more remarkable. Nano-crystalline carbide grain has small grain size, larger surface area and high surface reactivity. The experiments have prepared different sizes of WC powder 84% WC-15% Co-1% VC carbide ball gear tested and found that nano-crystalline carbide button required minimum sintering temperature, has the best hardness, strength, resistance wear resistance and impact toughness, which is beneficial for overall efficiency and extending the service life.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Application

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 16:01

Tungsten electrode including pure tungsten electrodes, rare earth tungsten electrode and composite tungsten electrode, the most widely used electrode is rare earth tungsten electrodes. Rare earth tungsten electrodes main include: thoriated tungsten electrode, ceriated tungsten electrode, lanthanated tungsten electrode, zirconiated tungsten electrode and so on. Tungsten electrode material having good arc performance, low electrode burning loss, long life and other good properties often used in welding, electric light and electric ionizer and other related fields. It has wildely application. Tungsten electrodes are a critical material in welding, plasma welding and cutting. Commonly, thoriated tungsten electrode usually used in welding. Thoriated tungsten electrode having low electron work function, can work well even under overload voltage. In addition, the electrode arc starting is stability when welding does not contaminate the welded parts. Besides, it has long service life. However, because thoriated tungsten electrode has radioactive contamination, therefore, at present, people often use ceriated tungsten electrodes in place of thoriated tungsten electrode used in welding field.

Tungsten electrode material having a low work function, high melting point and low growth pressure property, these features help to reduce load temperature, reducing electrode burning and sputter etching, thereby extending lamp life. Some researchers use the liquid-solid mixing method to produce rare earth tungsten electrodes, by processing making low-power metal halide lamp electrodes, and assembling into a 70W metal halide lamp whole. After analysis the property of different metal halide materials found that metal halide which made by dysprosium tungsten and dysprosium yttrium tungsten electrode has best splash performance and corrosion resistance.

Tungsten electrode is often used as a cathode in plasma generator. This electric ionizer commonly used in cutting, thermal spraying, welding, melting, new materials synthesis, ultrafine powder production and other high-energy ion bombardment environment, so that the cathode material should have good high temperature performance and wear resistance, in order to improve service life of the electric ionizer. Rare earth tungsten electrodes have the above excellent performance, it is considered to be the best material an in electric ionizer.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Bar for Thanksgiving Day

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 15:43

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

APT Preparing Gas Sensitive Material--Tungstate Bismuth

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 18:38

Currently the fuel cell type (electrochemical type) and a semiconductor type are widely used in gas detection equipment to detect the ethanol content. The semiconductor gas sensor is using the changing of physical properties when the semiconductor surface adsorbing the gas to detect the gas. It becomes a hot research of gas sensors field, because of its easy-to-implement integration, miniaturization, high sensitivity, and low power consumption and safe and reliable. At currently the normally materials used in semiconductor gas sensor are SnO2, WO3, ZnO, NiO, MgO, BaTiO3 ect.. The most important factor affecting the performance of gas sensing is the adsorption property, and the structure, morphology, size and specific surface area are directly related to its adsorption property. So, it’s very meaningful to development a new semiconductor material with special structure and morphology, surface area, strong adsorption performance and high response and high selectivity.

APT, bismuth nitrate to prepare sensitive material--tungstate bismuth with special structure by hydrothermal synthesis method, the steps are as following:

1. Adding bismuth nitrate into nitric acid solution, and stirring at 30-50°C till the solid bismuth nitrate dissolved completely;

2. Adding APT into the solution, and then adjusting the pH value to 0.5-2 by NaOH solution;

3. Continually stirring for 2 hours, and then transferring the solution to a pressure melting bombs for reacting at 140-190°C for 10min-12h;

4. Taking out the products after the reaction completed, and cooled down to room temperature, then separated by centrifugation, washed, dried, and then vacuum dried for 1~3 hours to obtain the sensitive material--tungstate bismuth with special structure.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

APT Producing Rare Earth Ion Doped Scintillated Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 18:35

Inorganic scintillated material is a new optical functional material, which absorbs energy in the X-rays, rays or other high-energy particles will emit ultraviolet or visible light. An important application of the scintillated material is coupled into scintillation counter with photomultiplier tube (PMT), silicon photodiode (Si-PD) or CCD detector, and becoming an important detection equipment of high-energy and nuclear physics, nuclear medicine. Ammonium paratungstate (APT) is an important raw material for preparing inorganic scintillated material, and doping with rare earth ions to improve its properties.

Inorganic scintillated material is a new optical functional material, which absorbs energy in the X-rays, rays or other high-energy particles will emit ultraviolet or visible light. An important application of the scintillated material is coupled into scintillation counter with photomultiplier tube (PMT), silicon photodiode (Si-PD) or CCD detector, and becoming an important detection equipment of high-energy and nuclear physics, nuclear medicine. Ammonium paratungstate (APT) is an important raw material for preparing inorganic scintillated material, and doping with rare earth ions to improve its properties.

The steps of APT producing rare earth ion doped scintillated film are as follows:

1. Dissolving APT into deionized water to form a solution;

2. Adding the complexing agent-- citric acid into APT solution and mixing well to obtain the first precursor containing with tungsten, the pH value supposed to be controlled among 7-10;

3. Adding the soluble salt containing with Eu and Ln into water or alcohol to form a second precursor containing with Eu and Ln, and the pH value is controlled among 2-4;

4. Mixing the first precursor and the second precursor uniformly to get a transparent sol precursor, in which the concentration of Eu plus Ln is 0.02-2.0mol/L;

5. A precursor film is formed from the precursor obtained in step 4 by spin coating or dip;

6. Calcining the precursor film at 400-700℃;

7. Carrying out the annealing treatment at 700-1000°C to obtain ion rare earth ion doped APT scintillated film.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Powder Injection Molding Research (2/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 17:37

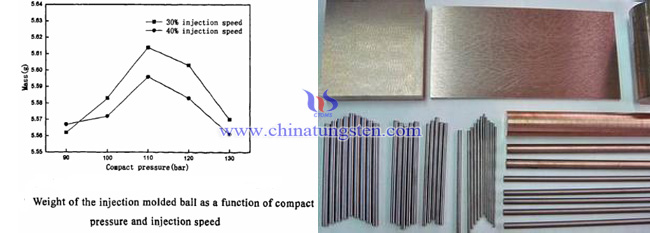

Many parameters of injection molding should be perfectly controlled, such as the temperature, the pressure, the speed and so on. Theoretically, in the process of injection molding, the temperature and pressure are the largest influencing factors of molding properties. In order to press tungsten copper powder mixture into the mold cavity, the temperature inside the injection machine must be high enough so that moderate viscosity mixing, the two-phase does not separate. For injection pressure (to overcome the flow mixing cavity flow resistance, provide filling speed and compaction of the melt) and speed in the experiment demonstrated that there is an optimal match range, pressure and speed should not be too large or too small. The following is the impact of temperature and injection table corresponding to the formation of body performance and injection molding pressure and injection speed of the blank:

From the figure above, we can also find the optimum temperature range for injection, injection pressure and speed. Since the injection process to fill the cavity is more complex, many parameters must be well controlled, once appear unreasonable control can cause a variety of defects. We introduce some common defects and the corresponding solutions: 1. Under-injection, it refers to the injection process feed can not fill the mold cavity, the corresponding solution is three-pronged approach from the injection temperature, feeding quantity and viscosity of the feed itself causes analyzed; 2. The pores, it is the most common type of defect, the corresponding method is to pay attention to whether the injection and mixing of air entrainment and make adjustments, check the injection speed, the injection pressure, etc; 3. Unstable quality, it should be considered that whether the powder is uniform and the segregation with the binder.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Powder Injection Molding Research (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 17:35

Based on conventional molding process and combines plastic molding industry technology, PIM (Powder Injection Molding) has excellent applicability in some tungsten copper products with small size and complex shape or structure. So we study from mixing, injection, degreasing, sintering and several key process of tungsten copper powder injection molding, and analyze and summarize the advantages of the process and the defects.

The first is the selection of the binder and the preparation of mixture. Binders can reduce caking of the powder, which has good flowability, and plays the role of maintaining the shape of the body until degreasing sintering. Thus the choice of the binder is injection molded in a key ring, it should meet the deformation and cracking does not occur before the product sintering defect, and easy to be removed. Now more use thermoplastic or some polymers as binders, such as paraffin, stearic acid, HDPE, EVA and so on. In the process of mixing, paraffin and stearic acid are liquid phase, which does not destroy the nature of the binder. In addition, wherein the order of addition of powder and a binder is the final state of the blank has a certain influence. The next is granulating, and select particles about 2-3mm for injection molding.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com