AMT Neutralization–Nanofiltration–Crystallization Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 17:07

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

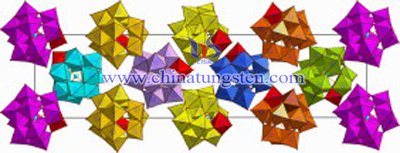

AMT Structure Study

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 17:04

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coins for Birthday Party

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 11:36

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coins for Diamond Wedding Anniversary

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 11:33

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Bars for Silver Wedding Anniversary

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2016 11:29

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing NaLaMgWO6 Powder

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 18:36

NaLaMgWO6 powder is the matrix of LED phosphor powder. LED is becoming the future development direction of the illumination source with the series advantages, such as low voltage and power consumption, high reliability, long life, environmentally friendly and energy-efficient. Phosphor plays an important role in the field of LED lighting. Tungstate is typically self-activated luminescent material, the stable emission spectrum, very wide intrinsic luminescence band, occupying most of the visible light region, thus strongly influence the emission band position. Therefore, ammonium paratungstate (APT) as the typical tungstate, is a matrix material with excellent light-emitting property, and can be used for preparing NaLaMgWO6 phosphor powder which is applied in LED. The steps as following:

1. Weighing NaNO3, La(NO3)3, magnesium acetate and APT at a certain proportion, and dissolving them in deionized water, then adding citric acid to prepare a solution named A; the molar ratio of citric acid : NaNO3 is (0.05~0.2):1;

2. Adjusting the pH value of solution A to neutral value;

3. The solution A is carried out a hydrothermal treatment, and then removed for centrifugation, washing and drying to obtain a sample powder;

4. Sintering the powder sample to solid phase, to obtain the NaLaMgWO6 powder. The solid-phase sintering conditions supposed to be: raising the temperature at the rate of 1~2℃/min from room temperature to 200~300℃, and then continually raising to 500-800℃ at 3~5℃/min, holding for 3~8 hours then cooling down.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

APT Preparing Fluorinated Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 18:31

Fluorination catalyst plays a central role in the reaction of gas phase catalytic fluorinated halogenated olefins, a method that using ammonium paratungstate (APT) and chromium hydroxide to prepare fluorination catalyst is proposed in this paper.

Steps like bellows:

1. Mixing the chromium hydroxide and APT a certain mass percentage, and pressing to obtain the precursor of product;

2. Calcining the catalyst precursor obtained in step 1 in the nitrogen atmosphere at 300℃~500℃ for 6~15 hours. In the calcination, a large amount of volatile compounds will be produced, and mainly is ammonia, making catalyst of high surface area, pore volume, thus enhancing the activity of catalyst;

3. Carrying out activation in the atmosphere of hydrogen fluoride and hydrogen (mixed gas mixed at a molar ratio of 10:1) at the temperature of 200℃~ 400℃ for 6 ~15 hours; in this process, all or part of the tungsten 6 will be reduced to tungsten;

4. Carrying out activation at 200℃~400℃ again, the atmosphere should be the mixed gas of hydrogen fluoride and chlorine at molar ratio of 10:1, for 6~15 hours, thus to get fluorination catalyst.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Anti-corrosion Research (2/2)

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 17:13

There is an experiment chooses WC-10(CoNi) tungsten carbide as an object of study. In order to test the anti-corrosion, it adds different content of Co in the binder and finds that Cr element effectively increases the anti-corrosion of tungsten carbide and the hardness increases with the increasing content of Cr. Another study is about corrosion behavior with WC-9Ni-0.57Cr carbide simulation in seawater, the study found that in deep-sea high pressure, corrosive environments on corrosion resistance is concerned, compared to conventional WC-Co carbide system to Ni-Cr alloy as the binder phase has better corrosion resistance.

Recently, some foreign scholars have also studied the correlation titanium carbide (TiC), tantalum carbide (TaC) and chromium carbide (Cr3C2) added impact on the corrosion resistance of the alloy. They believe that an appropriate amount of such reinforcement TiC ceramic composite materials can improve toughness of the alloy, and TiC and TaC has excellent chemical stability, only some of the acid is dissolved in, super acid and alkaline oxide solution: While Cr dissolved in the bonding phase accordingly in its surface layer of passive film is formed, it will not change the strength of the premise, significantly reduce the current density, and the higher the ratio of Cr alloy and Co, the passivity of alloy becomes higher. Furthermore, adding aluminum (Al) in the binder is also a new attempt of researchers. Theoretically, Al can be formed of metal bond compound (Co3Al), will make a fundamental change in the binder phase from the structure and performance, the amount can be increased to improve the content of Al alloy high temperature oxidation resistance and corrosion resistance.

The latest research has progressed to the development of adhesive-free alloy, which is free or very little binder metal content, high hardness (up 95HRA above), corrosion and oxidation resistance is also very good, but its flexural strength and fracture toughness is lower, which is difficult for machining. Overall, for the study of the corrosion of cemented carbide mainly includes three aspects, one is to replace the binder phase, and the second is to strengthen the binder phase by adding elements, hard phase grain refinement, the third is the development of adhesive-free tungsten carbide.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Anti-corrosion Research (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 17:11

Conventional tungsten carbide is composed of hard phase WC and the binder Co. Due to Co has good wettability on WC, tungsten carbide has high hardness, high density, high strength and excellent chemical stability, which can be widely used in some wear parts and cutting tools machining. But as binder, Co has poor anti-corrosion, especially for scour corrosion so that to add some other elements with good anti-corrosion or to find new binder becomes the new directions of related researchers. The principle of Co oxidation corrosion of WC and Co is formed of two electrodes in the electrochemical etching solution, to form a closed loop enclosing an electrolyte. WC as a catalyst to promote the electrolytic solution boundaries O2, producing O2-, forming a cathode; Co as the anode is oxidized and causes the corrosion.

The Common nickel (Ni) can effectively take place of the cohesive effect of cobalt (Co) and improve the anti-corrosion of tungsten carbide. But tungsten carbide hardness (HRA) affected its formation, as compared to the original cobalt tungsten carbide decreased 0.5-1 times, only 70-80% strength cobalt tungsten carbide, which is only suitable for less demand in strength, wear resistance situations. In addition, add chromium (Cr) in the binder is also a kind of common method to improve anti-corrosion of tungsten carbide. It can remarkably decrease the corrosion rate of tungsten carbide in corrosive conditions, refine tungsten carbide grains and strengthen the binder phase, which not only improve the anti-corrosion of tungsten carbide, but also promote other properties.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

AMT Production Technical State

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 16:54

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com