Ammonium Paratungstate Preparing ZrWMoO8 Composite Ceramic Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 19:22

The problem of thermal expansion is an unfavorable factor in many areas, which is widely existing in function and structure materials such as precision components, optical fiber, circuit boards, sensors and fuel cells. ZrWMoO8 composite ceramic material is an ideal expand controllable material.

Studies have pointed out a method that ammonium paratungstate preparing ZrWMoO8 composite ceramic material, the steps are as follows:

1. Weighing zirconium oxychloride, aluminum nitrate and dissolving them into 100~150mL of distilled water to prepare a solution A;

2. Dissolving ammonium paratungstate, tetra-hydrate ammonium molybdate, ammonium metavanadate into 100~150mL of distilled water, and heated with stirring to completely dissolve, then to obtain solution B;

3. Both solution A and B are slowly dropped with the same speed into a round-bottomed flask which is containing 50mL of ethanol, then white precipitate comes into being, stirring is supposed to be continually during the addition for ensuring mixing homogenous;

4. Transferring the solution to an evaporator for evaporation after the addition was completed, and then drying, milling to get a mixed powder;

5. Placing the powder in a muffle furnace at 550~650°C calcined for 2~3 hours, and then taking out to cool down to obtain a precursor;

6. The precursor powder is placed in a mold to form cylindrical specimens;

7. The precursor sample was placed in a molybdenum crucible with stamped, and placed into another ceramic crucible with a lid, the ceramic crucible is place into the resistance furnace when its temperature heated to 940~970°C. The ceramic crucible is calcined for 2 hours, and transferred into a dryer to cool down to room temperature after taken out and cooled down for 2 minutes, then we obtain the ZrWMoO8 composite ceramic material.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing Tungsten Bismuth Light Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 19:05

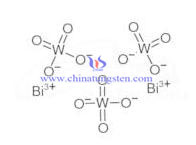

Handling the environmental pollution is the focus and urgent problems for human today, especially governance of organic pollutants. Photocatalytic technology has the advantages that low energy consumption, clean mild conditions, no secondary pollution, etc. in purify organic pollutants, being a green environmental control technology which has a broad application prospect. Tungsten bismuth (Bi2WO6), as a new type of bismuth series light catalyst, is a multi-compound with layered structure. And because of its high catalytic activity under visible light irradiation, it can decompose water to produce oxygen and degradation of organic matter, making it particularly suitable for environmental pollution control and solar energy conversion.

Handling the environmental pollution is the focus and urgent problems for human today, especially governance of organic pollutants. Photocatalytic technology has the advantages that low energy consumption, clean mild conditions, no secondary pollution, etc. in purify organic pollutants, being a green environmental control technology which has a broad application prospect. Tungsten bismuth (Bi2WO6), as a new type of bismuth series light catalyst, is a multi-compound with layered structure. And because of its high catalytic activity under visible light irradiation, it can decompose water to produce oxygen and degradation of organic matter, making it particularly suitable for environmental pollution control and solar energy conversion.

Studies have pointed out a method that uses ammonium paratungstate as a raw material for preparing bismuth tungstate with three-dimensional wheel-like hierarchical structure. The steps are as follows:

1. Dissolving the bismuth salt in dilute aqueous acid to form a clear solution;

2. Dissolving ammonium paratungstate by a certain percentage in deionized water to obtain APT aqueous solution;

3. Add APT solution slowly into the clear solution obtained in Step 1, and continue stirring for 0.5~l hour to obtain solution named A;

4. Dissolving an amount of sulfate in deionized water, and slowly adding it into solution A, and continue stirring for 0.5~l hour, to obtain solution named B;

5. Transferring B solution into a stainless steel autoclave containing Teflon-lined, and heated to 150~200°C for 10~30h, to generate products;

6. The products is washed and carried out centrifugation, and dried under vacuum at 50~100°C, to obtain the bismuth tungstate with three-dimensional wheel-like hierarchical structure.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Ceramic Nano Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 17:03

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Ceramic Semiconductor

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 16:57

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Buttons Wear Resistance Analysis (2/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 16:54

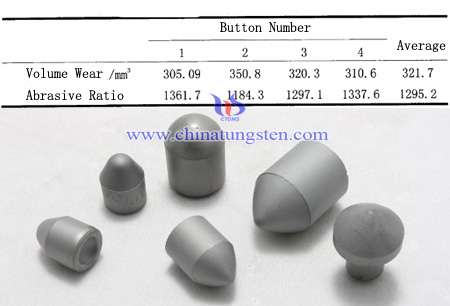

We can learn from the picture of part I that the abrasive ratio of tungsten carbide buttons grinding granite is about a thousand, and the lower the wear ratio and DTH drill button site work more consistent. Because in the DTH drilling process, most of tungsten carbide buttons failure caused by abrasion, only a small part is due to the impact of button fracture failure, particularly those with the gage side effects of buttons due to the maximum linear velocity so that the wear is also the most serious. In some high pressure DTH drill operations on its production process more stringent requirements, if the button wear failure require frequent replacement, so will greatly increase the cost of human and material resources. Therefore, the related researchers do some research on the impact of trace elements on the wear resistance of tungsten carbide buttons.

Generally, in order to refine tungsten carbide button (WC) grains, we can add grain growth inhibitors; improve the corrosion resistance of tungsten carbide button by adding corrosion-resistant components; for changing the properties of the alloy can be achieved by adding a refractory metal or rare earth elements and other methods. After a number of experiments and statistical data show that the most effective for WC-20Co carbide grain growth inhibitor and vanadium, niobium, tantalum, titanium, zirconium and other elements, addition of these elements contribute to grain refinement and increase wear resistance. Complex compounds of rare earth elements can occur with spherical added oxygen (O), calcium (Ca), sulfur (S) and other impurities, which change the distribution of impurities in the original interface. In addition, the wettability, the connecting strength of the interface and the wear resistance of cobalt (Co) on tungsten carbide (WC) has been remarkably improved.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Buttons Wear Resistance Analysis (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 16:49

With the developing technology and exploration, more and more machines or tools required working in strict conditions, such as high-pressure sealing, acid or alkali corrosion and so on. Tungsten carbide buttons have high hardness, high density, high strength, high melting point and excellent chemical stability, which can be widely used in mine, oil fields drilling, tunnel and rock stratum drilling.

Domestic scholars have done a lot of research, who use tungsten carbide buttons for granite grinding experiments. In the experiments, they use vertical lathe as the equipment, fix the invasion depth of tungsten carbide buttons that is the effective stress acting on the buttons, the grinding line speed to detect tungsten carbide buttons wear resistance. Although tungsten carbide button has higher hardness, it belongs to brittle materials, which working wear by friction is proportional to the amount of wear and tear theory calculation formula brittle relationship can be drawn carbide button wear volume of its units. The smaller the amount of wear of friction units of work, the greater tungsten carbide button abrasion and wear and abrasion resistance is inversely proportional to the volume. The statistics of tungsten carbide button volume wear and abrasive ratio given as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Ceramic Electrical Property

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 18:22

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Zn and Ti Doped WO3 Ceramic Thermoelectric Performance

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 18:21

With method of double doping, WO3-based ceramics ZnO and TiO2 doped can be made into samples with different molar proportions. According to the X-ray diffraction pattern, analyze each dopant and the generation of second phase by Jade5, and with doping concentration changing substances of second phase will shift. The molar ratio of 0.5% and 1.0% doping concentrations produced as Zn0.3 WO3 the second phase, with the increasing doping amount, materials of the second phase shift, becoming coexistence of Zn0.3 WO3 and Zn0.06 WO3, the second phase is completely transformed into Zn0.06 WO3 at 5.0% (mole fraction). According to the SEM scanning electron microscope image, it can be found that the grain size decreases and then increases. Measure thermoelectric properties of doped ceramic material in the temperature range of 300 ~ 1 000 K. The experimental analysis shows, the conductivity decreases and then increases, conductivity of 2.0% (mole fraction) doped sample is the worst. Seebeck coefficient of the sample is negative, indicating WO3 doped n-type base ceramic thermoelectric material properties have not changed. The absolute value of the Seebeck coefficient is monotonically increasing, and as for the Seebeck coefficient of 2.0% and 5.0% (mole fraction) of the sample, there are difference between regions of low temperature and high temperature. When the doping concentration is 0.5% (mole fraction), the power factor is maximum, which is 0.052 μW / (m • K2).

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Excellent Properties of TIG Welding

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:43

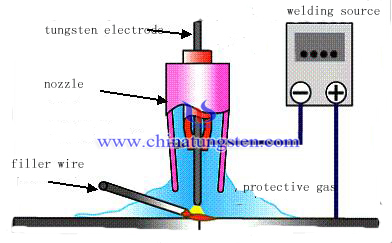

TIG welding has a lot of excellent properties.

1. TIG welding often uses argon as a protective gas. Argon arcs easy and stable. In addition, the density of argon is large, in the welding process can form a good protective cover, playing a good protection. And argon has large atomic mass, having a good cleaning cathode effect.

2. High weld quality, during welding process, argon gas does not react with the metal and not dissolved in the metal as well, so the whole welding process is simple main metal melting and crystallization processes, which is possible to obtain a high purity and quality welds.

3. Little welding deformation and stress, effecting by argon stream compression and cooling the arc heat is concentration, heat-affected zone very narrow, so the welding deformation and stress are small, which is suitable for sheet metal welding.

4. Easy to observation and operation, TIG welding is kind of open arc welding, so it is easy to observe, easy to operate, and suitable for all position welding.

5. Wide welding range, almost all metal materials can be welding, especially for welding lively chemical properties metals and alloys, such as aluminum, magnesium, titanium and other metals.

6. Stable arcing, TIG welding has stability current, and even in a small welding current can still stable combustion, which is suitable for thin plate materials producing.

TIG welding not only has large welding range, but also has high quality welding and can obtain high quality welds, so it is widely used in the industrial. With the development of science and technology, it is also often used as bottom welding for carbon steel and low alloy steel pressure pipe to improve the quality of welded joints.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TIG Welding and Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:40

Argon tungsten-arc welding (TIG welding) is kind of welding method, which is under the protection of inert gas, the electrode and metal will produce the arc heat to melt metal and filler wire. And TIG usually uses tungsten electrode as electrode. Inert gases include carbon dioxide, argon and others. Argon as the inert gas does not react chemically with the metal, and they are able to fully protect the metal bath not to be oxidized. In addition, at high temperature argon gas does not dissolve in the liquid metal, won’t easy to produce pores. Therefore, in TIG welding argon is usually as an inert protective gas, and which can obtain high-quality welds. According to the different type of power supply, TIG can be divided into DC TIG welding, AC and pulse TIG welding three types.

In TIG thorium tungsten electrode, tungsten electrodes, cerium tungsten electrodes are generally used. To choose different electrode tpye is generally based on the welding object and different powder supply types. For example, cerium tungsten electrode is mainly used in low-current DC welding, commonly used in small parts welding; Lanthanum tungsten electrode is suitable for AC welding, having excellent welding performance, is the most popular electrode; Thorium tungsten electrode’s performance than tungsten electrode is superior and it is widely used in DC welding area, but because it has a certain degree pollution, so the waste welding head should be well handled; Zirconium tungsten electrodes in AC environment has good welding performance, especially at high load currents, the zirconium tungsten electrode exhibited excellent performance is not a substitute for the other electrodes.

Major equipments of TIG tungsten electrodes include power supply, control box, torch, hydrogen systems and air-conditioning system. TIG welding can be divided to three types according to the operation approach: manual welding, semi-automatic welding, and automatic welding which GTAW (manual welding) is most widely used.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com