Tungsten Electrode Materials Analysis

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 16:48

Tungsten electrode material having strong electron emission ability, high elastic modulus, low vapor pressure and other good properties, so often as thermal electron emitting material used in various different areas. It also as an important part used in TIG welding, plasma welding and cutting. The minimum amount of pure tungsten electrode is 99.5%. It has a higher electron work function, so it is difficult to arcing and arc beam is instability. Besides the service life is short. The shortages of pure tungsten electrodes greatly limited its application.

Tungsten electrode in order to meet the development of modern industry, from the production process and raw materials employs a lot of analysis and breakthroughs. For example, base on the shortage of pure tungsten electrode some researchers have produced a new type tungsten electrode-rare earth tungsten electrode. Rare earth tungsten electrode uses tungsten as substrate, doped with some rare earth oxides which have low electron work function, common rare earth tungsten electrodes including: thoriated tungsten electrodes, ceriated tungsten electrodes, lanthanated tungsten electrodes, zirconiated tungsten electrodes and so on. Different types rare earth tungsten electrodes having different properties can select them according to the welding material and current conditions.

With welding industry continuous development, the reliability and stability of the electrode made more stringent requirements, on this basis, invented a new tungsten electrode type-composite rare earth electrodes. The study found arcing performance and properties of the composite electrode materials are better than rare earth tungsten electrodes, and ternary composite tungsten electrode property is better than binary composite tungsten electrode.

At present, China has less research on rare earth tungsten electrode and composite rare earth tungsten electrode. Besides, the production process of them is not mature, lacking large-scale development and promotion. China has rich resources of tungsten ore and rare earth resources, we have the advantage for large-scale electrodes production, if tungsten electrode materials research and development, China's tungsten electrode industry will be able to grab opportunities in the global market, has broad market prospects.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode–Balled, Pointed or Truncated Shape

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 16:42

As we know, different type and shape of tungsten electrode you used will influence the arc quality and welding performance that you will achieve. This article will brief introduce the performance and usage tip of different tungsten electrode shape.

A balled tip is generally used on a pure tungsten electrode. Besides, it is suggested for use with the AC process on sine wave and conventional squarewave TIG welders. What’s more the diameter of the balled end should not exceed 1.5 times the diameter of the tungsten electrode. Because a larger sphere at the tip of the electrode can reduce arc stability and/or fall off and contaminate the weld.

A pointed or truncated tip is generally used on pure tungsten electrode, ceriated tungsten electrode, lanthanated tungsten electrode and thoriated electrode. And a pointed or truncated tip of electrode should be used for inverter AC and DC welding processes. To process electrode tip to a pointed or truncated shape should use a grinding wheel specially designated for tungsten grinding which can avoid contamination and one that is made of borazon or diamond which can resist tungsten’s hardness. Note: if you are grinding thoriated tungsten, make sure you control and collect the dust, have an adequate ventilation system at the grinding station and that you follow manufacture’s warnings, instructions and MSDS sheets. What’s more, during grinding should put the tungsten electrode straight on the wheel versus at a 90-degree angle to ensure that the grind marks run the length of the electrode. So it will reduce the presence of ridges on the electrode that could create arc wandering or melt into the weld puddle, causing contamination.

Generally, when welding with lower currents on thinner materials, it is best to use the pointed tungsten electrode. Because A pointed tungsten allows the welding current to transfer in a focused arc and helps prevent thinner metals, such as aluminum, from becoming distorted. However, using pointed tungsten for higher current applications is not recommended. Because, at the higher current it can blow off the tip of the electrode and cause weld puddle contamination. So at the higher current, truncated tip will more suitable than pointed shape.

In any application, different type and shape of tungsten electrode has distinct advantages and disadvantages. That’s why, regardless of type of material you are TIG welding or whether you are using an AC or DC process, it is always important to choose tungsten electrode shape and type. Doing so can maximize your TIG welding success and is one of the best defenses against contamination and rework.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Warm Compacting Process Impact on Tungsten Copper Density (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 18:10

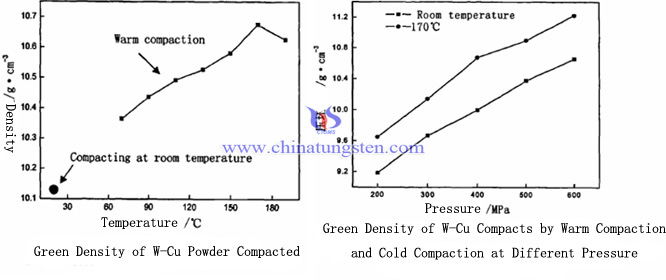

In addition, it is necessary that consider the glass transition temperature of the temperature and pressure of the main component of the binder, temperature and pressure temperature closer to the glass transition temperature, the better the viscous flow of the binder can form a good lubricating film on the particle surface, effectively reducing inter particle internal friction and external particles and mold wall friction, effectively increasing the density of tungsten and copper compacts. When temperature and pressure temperature exceeds the glass transition temperature of the binder, the binder near the melting point, viscosity decreases, lubrication is no longer obvious, friction coefficient rises, effectively suppress power drops down so that the compact density decreases.

Theoretically, for pressing pressure, the density of material by PM is increasing with the increasing pressing pressure. However, increasing the pressure is having some limitations, first of all it is necessary to subject to the applicable conditions of tolerance and mold equipment. Besides, the pressure should be chose according to the impact on tungsten copper compacts. By contrast green density at room temperature and pressure different pressing force, both of which are rising as the pressing pressure, green density increases. But at the same compaction pressure units, the density of tungsten copper green by warm compacting process is higher than the density of tungsten-copper compacts by cold compacting process. This is due to the molding temperature and pressure present in the adhesive film surface of the particles can effectively reduce the particle relative displacement resistance when pressing the powder particles are better able to transmit pressure, increasing the effective pressing pressure, which will help increase the density of compacts.

Furthermore, in the process of warm compacting process, the yield strength and hardening rate of metal powder grains decrease, which increases the plastic deformation of powder particles and is beneficial for improving the density of green. Concerning powder compacting law, many experts and scholars propose some famous equation of repression, combined with the requirements of production equipment as well as the relative performance of tungsten copper required, thereby rational use of temperature and pressure molding process to improve its green density.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Warm Compacting Process Impact on Tungsten Copper Density (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 18:08

Warm compacting process is a kind of new technology based on conventional molding process. Compared with conventional powder metallurgy (PM), warm compacting process require add special binder in the powder before compression and heating of moderate temperature lower than the conventional powder metallurgy desired temperature, then use conventional methods to obtain high-density powder compact was pressed. At present, warm compacting process can be widely used in some iron-based powder metallurgy parts fabricating, which can remarkably improve the density and properties of tungsten copper sintered body. We will discuss the process temperature and pressure applied on tungsten-copper material to analyze the impact of temperature and pressure from the temperature and pressure of pressing both temperature and pressure process of tungsten copper compacted density.

Temperature controlling plays an importance role in warm compacting process, in order to achieve the optimum temperature, related scholars at the same pressure do the compacting experiments at different temperatures. Experiment uses tungsten copper mixed powder (add 0.8% binder) at a pressure of 400MPa, at different temperatures for tungsten copper compacts pressed. Combined figure below we can see that the green density warm compaction under high pressure in cold forming the blank (at room temperature) as compared to the density. This is due to the cold pressing the powder in a binder lubricating can not work effectively, so the green density produced little effect; The temperature and pressure conditions in the binder may well play a role in improving the friction between the powder and the powder and die wall, thereby increasing the density of tungsten and copper compacts.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing Nanometer Tungsten Disulfide Powder

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 17:31

Metal sulfides can be generated by sulfur and metal, also can be generated from hydrogen sulfide (or hydrogen sulfate) reacting with metal oxide or hydroxide; it is a very important semiconductor material. With sulfide semiconductor playing an increasingly important role in people's lives and production, metal sulfides nanometer materials are cause strong research interests of scientists because of their broad play application in photocatalytic material, luminescent materials, nonlinear optical materials and light-sensitive sensor material. Tungsten disulfide, as a sulfide with unique properties, causes particular concern because when the temperature exceeds the critical value, the magnetic and conductive properties would be changed. It is widely used in solar cells, catalytic hydrodesulfurization reaction, as well as a photoconductive material and lithium - sulfur battery cathode materials and other aspects.

Ammonium paratungstate can be used as raw materials to prepare tungsten disulfide nano-powder with aluminum sulfide shell.

1. Using the traditional process to reduce ammonium paratungstate to high purity tungsten powder;

2. Tungsten and aluminum blocks pressed under the pressure of IMpa~IGpa from powder as the anode material of the plasma arc furnace, wherein the tungsten atomic share the percentage of 95~99%;

3. Using graphite electrodes as the cathode, tungsten and aluminum blocks as the anode;

4. Preparing nanometer tungsten disulfide powder by Arc Discharge Plasma Technology

Holding the distance of cathode (graphite) and anode (tungsten and aluminum blocks) between 2~30mm, carrying out the reaction under the protection of argon and hydrogen sulfide gas, and the arc discharge voltage 10~40V, then tungsten disulfide nano-powder with aluminum sulfide shell generated.

Remarks: the partial pressure of argon and hydrogen sulfide gas is respected to 0.01~0.5Mpa and 0.01~0.3MPa.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ion Exchange Method Removing Molybdenum from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 17:29

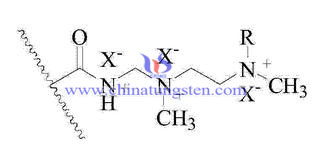

Tungsten and molybdenum are similar elements, with very similar properties in physical and chemical. Generally, molybdenum will exist with tungsten in the ore, but different precision ore with different molybdenum content. For getting production process, completely and effectively separating tungsten and molybdenum is a necessary link in the production process ammonium paratungstate. In traditional tungsten smelting process, there are many problems in the removing molybdenum step, for example: impurities removed not completely, huge cost, complex process and resin difficult to desorption. Therefore, studies on deeply removing molybdenum with the process ensured simple, and control costs are becoming especially meaningful. According to the problems enumerated above, using a multi-amine weakly basic anion exchange resin in the production process of ammonium paratungstate by ion-exchange method for deeply removing molybdenum is proposed in this paper.

In this method, multiple amine weakly basic anion exchange resin is used as the stationary phase, and ammonium tungstate solution containing with thiomolybdate anion as the mobile phase, carrying out anion exchange adsorption to make the thiomolybdate anion selectively adopted by multi-amine weakly basic anion exchange resin, thus to achieve the goal of separating tungsten and molybdenum effectively, and to obtain the high purity ammonium tungstate solution; then, further evaporation, concentration and crystallization to generate high purity APT crystals.

Noted: Multi-amine weakly basic anion resin can be desorption with low concentrations of sodium hydroxide solution (0.5mol / L), thus going to be reused.

The method that selectively removing molybdenum from tungstate solution by multi-amine weakly basic anion exchange resin has the advantages such as: effectively removal ; the resin can be reused to extend its service life; a short process, simple to operation, low cost, easy to applied in industrial.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Tungstate Produces AMT by Digestion in Silica

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 16:46

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Tungstate Produces AMT by Ion Exchange

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 16:41

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Selection Guide for Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 16:24

There are many tungsten electrode types, so how to identify select and prepare tungsten electrodes is very important for your application.Tungsten electrode is an important part in TIG (or GTAW) welding. Because tungsten electrode has many good properties such as high hardness and high temperature resistance to carry the welding current to the arc, and it has the highest melting point of any metal so it can be used in high temperature environment and without quickly loss.

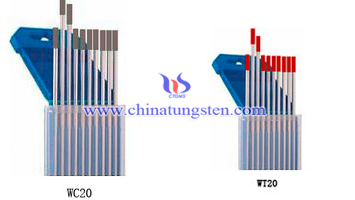

These non-consumable tungsten electrodes come in a variety of sizes and lengths and are composed of either pure tungsten or a hybrid of tungsten and other rare earth elements and oxides. According to the raw material it can be divided into these types: pure tungsten electrode, 2%thoriated tungsten electrode, 2% ceriated tungsten electrode, 1.5% lanthanated tungsten electrode, zirconiated electrode and other rare earth tungsten electrode. Choosing an electrode for the TIG process not only depends on the base material type and thickness, but also depends on welding alternating or direct current. There is a selection guide for selecting different type tungsten electrode.

Pure tungsten electrodes during welding can provide great arc stability for AC welding with balanced wave especially on aluminum and magnesium, but is not typically used for DC welding.

2% thoriated tungsten electrodes can increases electrode’s electron emission qualities, having lower consumption and eliminates arc wandering for greater stability. And it can use for welding some small thin steel and parts. But it has radioactivity and are only for specialty type AC welding.

2% ceriated tungsten not only can perform best in DC welding at low current settings but can be used proficiently in AC or DC processes. But using ceriated electrodes at higher amperages is not recommended.

1.5% lanthanated tungsten electrodes have excellent arc starting, low-burn-off rate, good arc stability and excellent re-ignition characteristics. It can work well on AC or DC electrode negative with a pointed end or they can be balled for use with AC sine wave power sources.

Zirconiated tungsten electrodes can produce an extremely stable arc and resists tungsten spitting. It is ideal for AC welding as it retains a balled tip and has a high resistance to contamination.

Rare earth tungsten electrodes has stable arc in both AC and DC processes, greater longevity than thoriated tungsten, the ability to use a smaller size diameter tungsten for the same job, use of a higher current for similar sized tungsten and less tungsten spitting.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Thoriated Tungsten Electrode and Ceriated Tungsten Electrode Comparing

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 16:18

2% thoriated tungsten electrode is the most commonly used electrodes among other tungsten electrodes. But with the environmental awareness increasing, thoriated tungsten electrodes now are gradually replaying by ceriated tungsten electrodes. Comparing these two different tungsten electrodes we will found they are a lot of similarities and differentia.

2% thoriated tungsten electrodes contain 97.30% tungsten and 1.70 to 2.20% thorium. It is the most commonly used electrode today. The reason why thoriated tungsten having widely application is it can increases electrode’s electron emission qualities, improving arc starts and allowing higher current carrying capacity. On the other hand, this electrode operation is far below than its melting temperature, so it has considerably lower consumption and eliminates arc wandering for greater stability. Besides, it has lower weld contamination level than other electrodes. What’s more, during manufacturing, thorium can evenly disperse throughout the electrode which allows the electrode to maintain a sharpened edge for welding thin steel. But, thoriated tungsten electrodes are only for specialty type AC welding, and they are exceptional for DC electrode negative or straight polarity on carbon and stainless steel, nickel and titanium applications. Further, thorium is radioactive. Therefore, during operation must always follow manufacture’s warnings, instructions and the MSDS for using.

2% ceriated tungsten electrodes contain a minimum of 97.30% tungsten and 1.80 to 2.20% cerium. It not only can perform best in DC welding at low current settings but can be used proficiently in AC or DC processes. But using ceriated electrode at higher amperages is not recommended. At higher amperages situation the oxides will migrate quickly to the heat at the tip, removing the oxide content and nullifying its process benefits. Ceriated tungsten electrodes have many excellent properties. For example, it can start the arc at low amperages and it is non radioactivity material, having longer service life than thoriaed tungsten electrode. On the other hand, ceriated tungsten electrode is widely used in orbital tube and pipe manufacturing, thin sheet metal work or small and delicate parts welding.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com