Tungsten Copper Power Properties Test (2/2)

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:23

Next, we introduce transmission electron microscope (TEM), which is a kind of high-powered high-resolution microscope. Compared with common optical microscope, it uses electromagnetic field as lens and was widely used in super-fine grain, aggregates and some nano-scale material testing. Furthermore, since the electron beam penetration is weak, so the specimens for electron microscopy of ultrathin sections shall be made about a thickness of about 50nm, which require ultra-microtome machining. For tungsten-copper powder, the thickness is more than 100nm, if the sample is required and the powder milled sample was dissolved in ethanol, in an ultrasonic cleaning after the suspension of the dispersed drops in the electron microscope with a copper medium carbon film, powder morphology was observed after drying.

Finally, thermal analysis, which refers to a change in endothermic or exothermic reactions that take place through the heating and cooling process and the quality of the material, the components was analyzed and identified substance. It includes that differential scanning calorimetry (DSC), which measuring thermal transitions within the material and relevant to the relationship between temperature and heat flow. The shape of the melting peak on DSC curve reflects the particle size distribution; the information can be drawn melting enthalpy crystallinity. Themogravimentric analysis (TGA) records that temperature changes and the time the sample quality, measurable by TGA analysis of injection molding material at different temperatures of weight loss situation, and in order to determine the heating rate of heat degreasing.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Power Properties Test (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:20

Tungsten copper powder properties itself will directly affect the final performance of tungsten copper products so that the test of tungsten copper powder raw material becomes vital. At present, laser particle size analysis, transmission electron microscope, differential scanning calorimetry are the main test methods, next we will introduce and analyze them by theory and working principle.

Laser particle size analyzer judges the size of particles by distribution (ie, scattering spectra) by the diffraction space or scattered light particles. The method combines Fraunhofer with Mie scattering theory, when a bunch of laser irradiation wavelength λ in the small spherical particles of a certain size, the beam encounters a barrier, diffraction and scattering phenomenon will occur. Generally, when the particle size is less than 10λ, the main phenomenon is scattering, while the particle size is greater than or equal to 10λ, the main phenomenon is diffraction.

The most widely used laser particle size analyzer currently usually uses 500-700nm wavelength laser as a light source, which test particles size above 5μm is relatively accurate. For particle size of less than 5μm by Mie theory is mathematically corrected, which means that for the sub-micron or nano-scale particles have a certain measure of error. In addition, theoretical model of laser particle size analysis is based on spherical particles and mono-disperse condition, and thus for the particle shape and particle size distribution will have a greater impact on the final results of particle size analysis. The more irregular shape of particle, the wider particle size distribution, the final error will be greater. For tungsten copper composite powders, the water as a dispersant and add ethanol for grinding, after 30 minutes of ultrasonic cleaning in distilled water dispersion of particle size analysis.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Recycling Ammonium Paratungstate, Cobalt, Nickel from Waste Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 16:23

With the economic developing rapidly, tungsten carbide used in each industry is being more and more widely, thus leading a huge demand and consumption of tungsten. The metal composition of carbide is almost rare metal elements, and tungsten takes a large proportion. The more consumption of carbide means the more consumption of rare metals, in this case, recover tungsten and other rare metals is extremely important.

With the economic developing rapidly, tungsten carbide used in each industry is being more and more widely, thus leading a huge demand and consumption of tungsten. The metal composition of carbide is almost rare metal elements, and tungsten takes a large proportion. The more consumption of carbide means the more consumption of rare metals, in this case, recover tungsten and other rare metals is extremely important.

The steps of recovery waste tungsten carbide are like bellows:

1. Melting tungsten carbide

Pour the waste tungsten carbide scrap into a furnace, and adding sodium bicarbonate or sodium carbonate, then heating to 800~1200℃ to get carbide mixture;

2. Preparation of sodium tungstate

Pour the carbide mixture into water to generate a solution containing with sodium tungstate and precipitate, and then filter to separate sodium tungstate solution and solid matter;

3. Preparation of ammonium paratungstate

Sodium tungstate solution goes through extraction and adding ammonia to generate ammonium tungstate solution, heating to evaporate APT crystal;

Further more, the APT is dried, and calcination to obtain tungsten oxide, and then reduced to tungsten powder in a hydrogen atmosphere;

4. Extract cobalt, nickel and other metals from the solids

1) Mix the solid with hydrochloric acid solution (concentration of 10-30%), and then filter to separate the precipitate and liquid;

2) Taking liquids, removing the impurities of iron, and then carrying out extraction to separate liquids containing with cobalt and nickel;

3) Add ammonium oxalate solution respectively into the liquids containing with cobalt and nickel, and precipitation, filtration, evaporation and drying after the reaction is completed, to obtain solids that cobalt and nickel oxalate, then reduced to obtain cobalt and nickel powder;

4) Take the precipitate to calcine and melt for second time, and then get tantalum and niobium by dissolving it in water.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing Tungsten Carbide with Gradient Cobalt Content Change at Surface

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 16:19

Cobalt is the metal with shiny steel gray. The tool made by steel containing a certain amount of cobalt can significantly improve the wear resistance and cutting performance, so cobalt often used for making carbide. The content of cobalt at tungsten carbide surface affects its performance, specific performance as bellows:

1. The cobalt content of outermost layer is lower than the nominal cobalt content, and then the carbide will have high hardness and wear resistance;

2. The cobalt content of middle layer is higher than the nominal cobalt content, and then the carbide will have good hardness and abrasion resistance.

In this paper, a method that preparing tungsten carbide with gradient cobalt content change at surface from ammonium paratungstate, the carbide produced has normal core tissue, the mechanical properties and service life are improved. Steps are as follows:

1. Prepare a paste of ammonium paratungstate

APT is dissolved at a concentration of 2%~4% polyvinyl alcohol solution to obtain a paste of ammonium paratungstate, the amount of APT added is 6~8 times the amount of polyvinyl alcohol solution;

2. Carbide surface infiltration tungsten

Wrapping carbide in the paste ammonium paratungstate, and heated to 800~900°C in a hydrogen atmosphere, continually heated to 1400~1460°C after incubation for 20~40 minutes heating, then incubation for 1~2 hours, taken out and cooling down under a hydrogen atmosphere;

3. The solid carburizing

Add carbon black at a temperature of 1420~1450°C for 0.5~2 hours

4. Decarburization phase generated

Ammonium paratungstate is heated to about 900°C at a hydrogen atmosphere, activity W and tungsten oxide can be obtained, and then reacted at a constant temperature 1400~1460°C for some time, thus to get tungsten carbide with gradient cobalt content change at surface.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Functional Ceramics And Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 04 March 2016 17:03

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Ceramic Nonlinear I-V Characteristics

- Details

- Category: Tungsten Information

- Published on Friday, 04 March 2016 16:58

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide – Polycrystalline Diamond Buttons Impact Resistance (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 04 March 2016 16:39

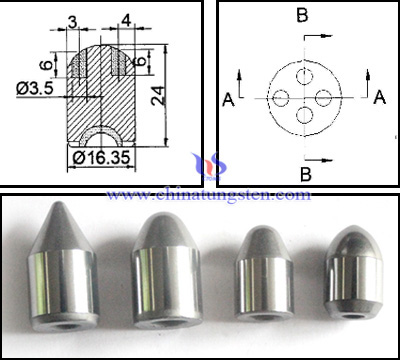

Another purpose of this experiment is to show that the experimental data on the number of polycrystalline diamond composite button impact on the resistance of polycrystalline diamond buttons, tungsten carbide substrate by more marked hole inserts welded certain number of polycrystalline diamond can effectively improve the wear resistance of tungsten carbide buttons. The schematic diagram of 1-4 PCD inserts welded tungsten carbide - polycrystalline diamond composite buttons as follow:

From the figure we can be more clearly seen in the PCD carbide ball symmetrically distributed around the button tip, the tip of the general impact of the maximum stress endured so cemented carbide substrate is usually not tip inserts welded polycrystalline diamond PCD damaged by great impact energy. Experimental results show that a polycrystalline diamond insert welded carbide - polycrystalline diamond composite ball gear not rupture under impact action 30J-70J, that within the impact resistance of safety values. For φ16mm diameter high pressure DTH drill site operations in the approximate range withstand the impact energy also falls within this range, it is considered that a polycrystalline diamond insert welded carbide - polycrystalline diamond compact button able to meet the requirements of DTH drill. However, when the hole of tungsten carbide basis is more than 3, its impacting resistance will remarkably decrease (starting to destroy when the impact energy is higher than 50J). Therefore, for tungsten carbide – polycrystalline diamond button, the more polycrystalline diamond does not mean the better properties, which has a optimum range and the effect subjects to normal distribution.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide – Polycrystalline Diamond Buttons Impact Resistance (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 04 March 2016 16:37

Tungsten carbide – polycrystalline diamond button is based on tungsten carbide and punching for polycrystalline diamond welding, which makes this composite buttons not only have excellent hardness and impact resistance, but also the defect of wear resistance can be made up by polycrystalline diamond. Theoretically, tungsten carbide – polycrystalline diamond buttons can be perfectly suitable for the requirements of impacting resistance of DTH drills. In order to prove this inference, related researchers design the interior impact test, which was calculated using the results of DTH drill buttons at the construction site of the state power to withstand the impact of granite, the impact test simulates the maximum extent carbide - PCD composite buttons as the actual working environment DTH drill buttons.

The experiments use tungsten carbide – polycrystalline diamond button reference φ115 DTH drill diameter edge button φ16mm by comparing the number of different inserts welded polycrystalline diamond (1-4) composite ball gear respectively 30J, 50J, 70J the number of times the impact energy of the impact, the impact is 100 times. If tungsten carbide – polycrystalline diamond buttons do not break within 100 times under the impact energy, we can confirm that this impact energy within the safety value. Afterwards, combining different types of DTH drill requirements for impact resistance buttons, it is possible to obtain more rigorous carbide - polycrystalline diamond composite buttons can meet the respective DTH drill impact resistance requirements.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tantalum Carbide Recovering Ammonium Paratungstate,Tantalum

- Details

- Category: Tungsten Information

- Published on Friday, 04 March 2016 15:47

Tantalum, an inactive metal element, symbiosis with niobium, is mainly existed in tantalite, with moderate hardness and full scalability, low coefficient of expansion. Since the tantalum surface will produce stable protective film of Ta2O5, thus blocking the continually reaction, and makes that tantalum has a very good corrosion resistance.

Tantalum, an inactive metal element, symbiosis with niobium, is mainly existed in tantalite, with moderate hardness and full scalability, low coefficient of expansion. Since the tantalum surface will produce stable protective film of Ta2O5, thus blocking the continually reaction, and makes that tantalum has a very good corrosion resistance.

Tantalum carbide is based on tungsten carbide alloy composed of cobalt and titanium, its composition is of complexity. Tungsten can be easily recovered in the form of ammonium paratungstate because of the large amount; however, niobium and tantalum with the low levels, therefore only recovered as a general enrichment, so there are a variety of recycling processes have been developed. Zinc Treatment and Molten Sodium Nitrate Enrichment are two of the common methods, the steps seen as following.

Zinc Treatment Method

1. The sintered carbide is decomposed with liquid zinc at 800℃, to break down the bonds of carbide particles and bonds between titanium and cobalt;

2. The decomposition products are carried out vacuum distillation to separate the zinc out which can be recycled;

3. The products after removal of zinc are oxidation and finely grounded, and then go on with alkali treatment and flooding, etc., to make tungsten leaching into the fluid in the form of NaWO3, thereby ammonium paratungstate is prepared to recycle tungsten;

4. Use sulfuric acid to leach cobalt and titanium, the leaching residue obtained is the tantalum and niobium concentrate, then further separation to recover cobalt and. tantalum.

Molten Sodium Nitrate Enrichment Method

1. The waste carbide together with sodium nitrate are melt processed at the temperature of 700~800℃ to make the carbide decomposition and oxidation;

2. Add water into the melting for leaching out tungsten, thereby preparing ammonium paratungstate to recover tungsten;

3. Filtration, separation the Tungsten-containing solution and residue, and then add hydrochloric acid to leaching out cobalt to recover cobalt;

4. Finally, recover tantalum and niobium concentrate in hydrochloric acid leaching residue thus to recovery of tantalum and niobium.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing Metatungstate Solution

- Details

- Category: Tungsten Information

- Published on Friday, 04 March 2016 15:43

Metatungstate is one of many types of tungstate, the only compound which the structures have been identified as colorless crystals. It has high solubility in water, and can be derived from metatungstate. Since the metatungstate itself is extremely unstable and easily degradable, therefore, it has a large difficulty in preparation. In the traditional way, sodium tungstate often used to prepare metatungstate crystals, but the complex process, high production costs, low productivity, poor product quality and the environmental pollution and other defects make the way no to be better. Nowadays, harmonious environment, cost savings, simplified procedures are promoted, so its necessary to develop a process which has the simplified process, low cost and environmental pollution, and also conducive to industrial producing metatungstate.

Metatungstate is one of many types of tungstate, the only compound which the structures have been identified as colorless crystals. It has high solubility in water, and can be derived from metatungstate. Since the metatungstate itself is extremely unstable and easily degradable, therefore, it has a large difficulty in preparation. In the traditional way, sodium tungstate often used to prepare metatungstate crystals, but the complex process, high production costs, low productivity, poor product quality and the environmental pollution and other defects make the way no to be better. Nowadays, harmonious environment, cost savings, simplified procedures are promoted, so its necessary to develop a process which has the simplified process, low cost and environmental pollution, and also conducive to industrial producing metatungstate.

Studies have pointed out that ammonium paratungstate (APT) can be used to prepare metatungstate solution. The steps as following:

1. APT powder heated to 270℃~350℃ for 30-60 minutes to dissociate, thus to generate ammonium metatungstate;

2. Add ammonium metatungstate powder into deionized water to leaching with stirring to get an emulsion;

3. Carry out filtration to remove insoluble, and the filtrate was placed in a water bath of 60~90℃ aging for 4~24 hours;

4. Filtered again, and exchanged by Cation Resin, then we get metatungstate solution.

As we can see from the above, the method APT used as raw material to prepare metatungstate solution has the advantages like: simplify process, easy to control, and low cost; In addition, since the reaction process doesn’t introduce any impurity element, so the purity and quality of metatungstate can be ensured; finally, the production process does not use ether and other volatile organic compounds, with minimal impact on the environment, so it is suitable for industrial mass production.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com