Ammonium Paratungstate Preparing Nano-Scale Zirconium Tungstate--Hydrothermal Synthesis Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 18:04

Zirconium tungstate belongs to ceramic materials, its widest temperature range of negative effects of expansion, high negative thermal expansion and maintain isotropic, making it one of the hot negative thermal expansion material of a Subsidiary . Zero expansion or low expansion material can significantly improve the thermal stability and geometric impact resistance. In this article, nano-scale zirconium tungstate with uniform particle size and negative good expansion properties is prepared from ammonium paratungstate and zirconium oxychloride by hydrothermal synthesis method.

Steps as follows:

1. Take an appropriate amount of ammonium paratungstate and thermal decompensate under a certain conditions to obtain ammonium metatungstate;

2. Respectively take and weight the zirconium oxychloride and ammonium metatungstate according to a certain proportion, and then formulate into zirconium oxychloride and ammonium metatungstate solution;

3. Stirring the AMT solution, and adding zirconium oxychloride solution at the same time, continually stirring and preheating the solution to 60~70 ° C for I~3 hours; and then adding hydrochloric acid solution with stirring and heating to 80~100°C for 2.5~3.5 hours, then zirconium tungstate precursor suspension got;

4. Zirconium tungstate precursor suspension is carried out hydrothermal reaction at 170~190°C for 4~6 hours, and then cooled down, the precipitate was collected and washed to remove Cl-; after dried, the precipitate is calcined at a 800~KKKTC for 1~5 hours to obtain the product we need.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Production of Tungsten Electrode Used in Rare Earth Fused Salt Electrolysis by Activated Sintering Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 16:14

Using fused salt electrolysis method for rare earth metals production need to use refractory and corrosion metal as cathode and cathode material usually chooses molybdenum electrode or tungsten electrode. Fused salt electrolysis method for rare earth metals production usually requires high temperature and the cathode should has corrosion resistance property. Tungsten electrode and molybdenum electrode has good high temperature performance and corrosion resistance property, therefore become the preferred cathode material. However, comparing molybdenum electrode with tungsten electrode, molybdenum electrode corrosion resistance is poorer than tungsten electrode, and consumption is faster. On the other hand, some rare earth has a strict requirement on impurity content and molybdenum is one of impurity element of rare earth. So many manufacturers will use tungsten electrode as cathode using in fused salt electrolysis for rare earth production instead of using molybdenum electrode.

Tungsten electrode production usually uses powder metallurgy method and the key process of this method is sintering. When tungsten bar diameter is less than 20mm, they usually directly use vertical furnace for tungsten bar sintering. When tungsten bar diameter is larger than 20mm need to use intermediate frequency sintering furnace for sintering and after sintering need to process forge. However, both methods require higher sintering equipment and there will have welding difficult as well. Thus, most manufacturers choose activated sintering method for tungsten electrode sintering. This method is using physical or chemical means to reduce sintering temperature and increase sintering speed, thereby increasing the density and associated performance of electrode.

Using activated sintering method to produce tungsten electrode so it can use in fused salt electrolysis for rare earth metal production and the detail production processes are as follow:

1. Mixing powder: making a small amount of the activator nickel salt dissolves in ethanol, and then pours this solution into tungsten powder and mixing well.

2. Pressing: mixed tungsten powder to dry under the protection of hydrogen, nickel will coat on tungsten particle surface, then using cold isostatic pressing presses tungsten powder into a billet.

3. Sintering: after pressing to sinter pressed tungsten powder into a billet can obtain tungsten electrode.

The experiment found that using nickel-coated tungsten powder as raw material for tungsten electrode production which produces by activated sintering method has better property than traditional tungsten and molybdenum electrodes.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

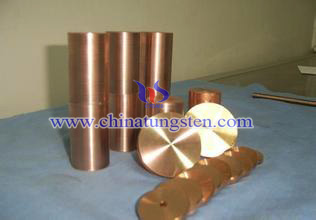

Tungsten Copper Sintered Properties (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 16:10

Electric Conductivity Test: It is a relative simple process that put tungsten copper (W-Cu) sintered body with high surface roughness grinded by metallographic abrasive paper on the equipment, and generally use alternating current bridge method, first determine the resistivity of the formula, and then through the relationship between conductivity and resistivity calculate the conductivity, but also during the relative conductivity values were calculated (based on the relative value of conductivity international standard soft copper is annealed conductivity of copper is 100% 1.7241μΩ • cm conductivity).

Shrinkage Test: It is essential that Measure the diameter and thickness of the blank with a caliper, sintered tungsten copper will be erased and the surface of the sintered powder with a caliper at this time of the diameter and thickness were measured again. According to the formula to calculate the radial shrinkage of the shrinkage of the sintered body (SD = (D-DS) / D × 100%, D is the diameter of the green body, DS is the diameter of a sintered body, SD is a radial shrinkage of the sintered body).

SEM: (Scanning electron microscope) SEM adapts a focused electron beam on the surface of tungsten copper samples at a predetermined time and space sequence gate intensive scanning secondary electron interaction with the sample signal transmission, the transmission must change after two photoelectric conversion by point presentation on the microscopic screen, whereby the reaction of the sample surface topography secondary electron image. In addition, the sample of SEM can be block or powder, but it should be noticed that vacuum can ensure the stability. For magnetic sample should be demagnetized in advance in case that the electron beam was observed to prevent being affected by magnetic fields.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Sintered Properties (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 16:08

Tungsten copper composite sintered body directly affects the comprehensive performance of final product so that the determination of the relative aspects of density, hardness, conductivity, shrinkage, scanning electron microscopy and crushing strength becomes essential. Next, we will combine the experience of some relevant theoretical principles and production practices as summarized in one by one analysis of the test method.

Relative Density Test: It usually uses Archimedes drainage method, which weighs tungsten copper sintered in the air and in distilled water separately by electronic balance. Subsequently removed with a filter paper and then sintered body dry surface of the water and drying weighed. The conclusion that the actual density tungsten-copper sintered body, the relative density and opening rate formulas based on Archimedes' principle.

Hardness Test: Different from Rockwell hardness of tungsten carbide, tungsten copper products commonly tested by Vickers hardness. The basic process is to measure metallographic sandpaper good surface finish to standard mirror wafer sample was placed on a micro hardness tester, then a relative angle between the plane of a rectangular pyramidal diamond indenter of 136 °, using 0.1kgf (0.98N) pressure pressed into the sample surface. After a period of time (usually set 10S), remove the pressure with a magnification of 40 times optical microscope to accurately measure the length of indentation diagonal by formula Vickers hardness (HV = 0.1891 × F / d2, HV Vickers hardness, F is the applied pressure, d is the amount of indentation diagonal arithmetic mean) obtained the hardness.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 15:12

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Bars For Wedding Gifts

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 13:41

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coins For Golden Wedding Anniversary

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 13:37

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TIG welding and Tungsten Electrode Property Requirements

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 12:06

TIG welding is also known as inert gas shielded arc welding. It usually uses high melting point metal such as thorium tungsten, cerium tungsten, tungsten and other refractory metal as non-consumable electrode of electric arc, using inert gas as the medium of electric arc and protective atmosphere, so that weld pool and electric arc will not affected by air during welding. It was proposed in 1930 when aviation industry has strived to develop at that time. On the other hand, SMAW and SAW welding can not meet airline industry non-ferrous metal welding. Besides, atomic hydrogen welding is more dangerous, and there will be welding line problems. Therefore, in order to meet the aviation industry non-ferrous metal welding requirements, TIG emerged.

Using TIG welding for metal welding not only has stable arc length and tungsten electrode difficult to melt, but also it has good protect effect and reliable crafts. It is suitable for welding non-ferrous metals and their alloys and welding material thickness is generally less than 3mm. TIG welding equipment including: welding power supply, ignition unit and control system; protection gas supply device; cooling water; welding gun and so on.

Tungsten electrode is an important part of TIG welding. Tungsten electrodes, thorium tungsten electrodes, cerium tungsten electrodes, zirconium tungsten electrode, yttrium tungsten electrode, lanthanum tungsten electrode and other composite tungsten electrodes are usually used in TIG welding. Each tungsten electrodes species has its own characteristics. Depending on different welding application can take different tungsten electrodes type. Tungsten electrodes are used in TIG welding having some property requirements:

1. Arc is easy ignition and stable;

2. The arc happens at the electrode front-end, without cathode spots climbing;

3. During welding, electrode consumption and deformation will not affect the property of the arc.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Pisces Tungsten Gold-Plated Coin

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 11:59

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Aquarius Tungsten Gold-Plated Coin

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 11:57

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com