Nuclear Technology And Tungsten Alloy Shielding

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 17:14

Nuclear technology refers to the modern new and high technology and one of the signs of social modernization which is based on the nuclear reaction, nuclear properties, nuclear effect and nuclear spectroscopy, and with radiation source, nuclear radiation detector, accelerator and reactor as its tools. Nuclear technology is an important method for early diagnosis of certain cancers, coronary heart disease and brain dysfunction. Its sensitivity, selectivity, specificity, interference, penetrating are so high that it is widely used in various fields of national economy as well as medical care, food preservation, agriculture, industry and hydrology aspects. Nuclear technology can be divided into military nuclear technology, nuclear power and civilian nuclear technology, of which civil nuclear technology is the most active, including radiopharmaceuticals, radiation processing technology, nuclear diagnostic technology, nuclear instrumentation, nuclear analytical techniques.

Nuclear technology refers to the modern new and high technology and one of the signs of social modernization which is based on the nuclear reaction, nuclear properties, nuclear effect and nuclear spectroscopy, and with radiation source, nuclear radiation detector, accelerator and reactor as its tools. Nuclear technology is an important method for early diagnosis of certain cancers, coronary heart disease and brain dysfunction. Its sensitivity, selectivity, specificity, interference, penetrating are so high that it is widely used in various fields of national economy as well as medical care, food preservation, agriculture, industry and hydrology aspects. Nuclear technology can be divided into military nuclear technology, nuclear power and civilian nuclear technology, of which civil nuclear technology is the most active, including radiopharmaceuticals, radiation processing technology, nuclear diagnostic technology, nuclear instrumentation, nuclear analytical techniques.

Nuclear technology not only has brought a variety of convenient, but also brought the nuclear radiation. For the question about the long-term effects of nuclear radiation on people, the study of Atomic Energy Commission geneticist James • Nair and his colleagues shows that the probability to have cancer for the people surviving from nuclear radiation is higher than ordinary people. In fact, many survivors suffered from thyroid cancer, lung cancer, breast cancer, leukemia and other cancers, and some people suffered from mental abnormalities after Hiroshima and Nagasaki nuclear explosions suffered. Many examples show that pregnant women subjected to nuclear radiation can lead to fetal malformation, fetal death and other diseases.

Tungsten alloy shielding can effectively shield the nuclear radiation generated in the use of nuclear technology to avoid it causing harm to humans. Since tungsten alloy combines high density, good machinability, good corrosion resistance, high radiation absorption capacity and high intensity, it is the best raw materials for radiation shielding. In the situation of reducing the volume and thickness of shielding, the radiation shielding performance of tungsten alloy shielding is still equivalent to that of lead. In addition, compared to lead and depleted uranium, tungsten alloy is more environmentally friendly.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater for Evaporation Coating

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 10:10

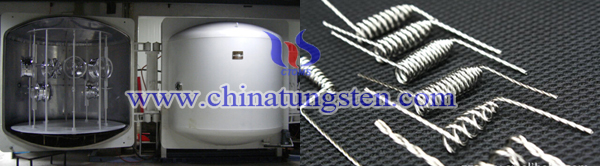

Vacuum evaporation coating has developed rapidly in recent years, glass, plastic, ceramic, metal, and other based material can be coated. Aluminum, copper, silver and their alloys can also be used as the coating material. Most vacuum aluminizing technology use tungsten wire as a heating source (tungsten heater). First of all, the plated workpiece should be clean, load it on a shelf in a sealed room. Accordance to the classification of application, coating machines have been designed into a stationary, rotating and both revolution and rotation and other types. The wolfram heater can be inserted in the position that is close to the plated object, when the degree of vacuum is higher than 5 × 10-4 Torr, the tungsten wire is energized and heated, the molten aluminum will be evaporated into an aluminum atom, and it will condense on the surface of the plated object, forming bright and non-transparent film with 3-5 microinch.

According to statistics, the amount of interpreters which need tungsten heater for vacuum coating is constantly increasing in China. And in order to save the use of silver, China continues to promote the new technology of vacuum aluminizing mirror. And vacuum evaporation coating machine in has been widely used in China. What’s more, the amount of using of tungsten heater is also increasing year by year. United States, Japan, Sweden, Germany and other countries still use wolfram heater, so exports are also on the rise.

Secondly, use value of high quality wolfram heater is twice as much as the poor quality wolfram heater, so improving the quality of wolfram heater has an important influence. In order to reduce the consumption of tungsten, it needs to improve the quality and its reasonable application. If the use of wolfram heater can be stabilized at around 18 times in a week, then the product will be able to meet customer needs.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Non-Filled Tungsten Bronze Type Materials

- Details

- Category: Tungsten Information

- Published on Friday, 03 June 2016 19:51

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Medical Radiation Protection Door

- Details

- Category: Tungsten Information

- Published on Friday, 03 June 2016 16:52

With the development of medical technology, medical radiation technology is more and more widely used in medical field. It is not only can be used to help doctors diagnose and treat various diseases, but also can be used to sterilize medical instruments. For example, in the medical diagnosis, X-ray can be used to determine the abnormal changes occur in the body organs and tissues. Doctors can study the patients' situation by injecting radioactive isotope into the body and producing the dynamic or stereo images with the help of imaging techniques and computer technology; in disease treatment, gamma rays or X rays emitted by the radioisotope can kill cancer cells, thereby effectively inhibit tumor growth; in the field of radiation sterilization, gamma rays can also be used to sterilize disposable medical supplies, medical equipment and the like. Radiation sterilization is more effective and cheaper than steam sterilization.

With the development of medical technology, medical radiation technology is more and more widely used in medical field. It is not only can be used to help doctors diagnose and treat various diseases, but also can be used to sterilize medical instruments. For example, in the medical diagnosis, X-ray can be used to determine the abnormal changes occur in the body organs and tissues. Doctors can study the patients' situation by injecting radioactive isotope into the body and producing the dynamic or stereo images with the help of imaging techniques and computer technology; in disease treatment, gamma rays or X rays emitted by the radioisotope can kill cancer cells, thereby effectively inhibit tumor growth; in the field of radiation sterilization, gamma rays can also be used to sterilize disposable medical supplies, medical equipment and the like. Radiation sterilization is more effective and cheaper than steam sterilization.

Since the radiation is widely used in medical treatment, the radiology department and a variety of medical equipments also appeared in major hospitals. Tungsten alloy medical radiation protection door is used for shielding and absorbing medical ray radiation, to protect the health of patients, their family members and medical workers. Medical radiation (such as X-rays, gamma rays, etc.) can inhibit, destroy and even kill human cells, resulting in the emergence of various changes in human physiology, pathology and biochemical aspects. It can enter the human body to destroy the molecular structure of living cells and disturb the chemical processes in the human body. Medical-ray radiation can also cause radiation sickness.

Tungsten alloy medical radiation protection door is made of tungsten heavy alloy with high density. Since the radiation shielding properties of a metal material increases with its density, so that the tungsten alloy medical radiation protection door has excellent radiation shielding ability, which can effectively shield medical ray radiation. In addition, compared with other radiation protection door materials (such as lead), tungsten alloy radiation protection door is nontoxic, neither endanger human health, nor pollute the environment.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding And Protection Of Medical X-Ray

- Details

- Category: Tungsten Information

- Published on Friday, 03 June 2016 16:49

With the development of modern medicine, X-ray has gradually become an indispensable part of the medical treatment, diagnosis, drug analysis aspects, but its harm to our health also attracted attention. X-ray can reduce white blood cell in the blood, leading to the human immune function decline. When the human body is irradiated with the X ray, X ray can interact with human cells and tissues to cause ionization material, thereby undermining the proteins, DNA and other macromolecules structure, causing the damage to the cellular structure. X-ray can also cause hair loss, skin burns, eye disorders, leukemia, skin cancer, cataracts and other radioactive diseases. Pregnant women irradiated by X-ray during pregnancy can lead to fetal death, teratogenic, severe mental decline.

Tungsten alloy shielding can be used to shield X-ray to protect humans from radiation damage. Compared with conventional shielding materials (such as lead), tungsten alloy shielding has higher density. Therefore, under the same weight, tungsten alloy shielding is much thinner, and its volume is only the 1/3 of lead shielding, while its radiation absorption capacity is unabated. This is why tungsten alloy is the best raw materials of radiation shielding.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold Commemorative Coin for Classmate Party

- Details

- Category: Tungsten Information

- Published on Friday, 03 June 2016 15:31

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact Defects and Solution

- Details

- Category: Tungsten Information

- Published on Friday, 03 June 2016 15:11

Copper infiltration is one of the most common forms of consolidation molding process, which is also an ideal molding process of tungsten-copper alloy melting point and a high melting point metal alloy two-phase psudoalloy composite materials. Compared with conventional mixing sintering, it can effectively eliminate the pores and defects and not need the subsequent processing (forging, re-sintering) can achieve good densification. So it has a broad prospect in electrical contacts fabricating. Tungsten copper contacts have been widely used in high or extra high voltage electrical equipment, circuit breakers, switches. Its fabricating process includes powder mixing, pressing, sintering, infiltrating and solidification, and any defects of each process will directly affect the properties of tungsten copper contacts finally.

Copper enrichment: it is also known as copper pool or copper depression. The reason for this phenomenon is due to induced copper powder large in size has been added in the mixing process. And it is pressed to the strip, the strip leaving melted pores are filled with liquid copper infiltration; the other one is when the mixed powder into a large ball, ball or adding too much copper induction before mixing was pressed into a sheet, and pressing time and pressing a direction parallel.

Tungsten enrichment: W skeleton has certain strength and the interconnected pores or channel system consist of solid grains or grain net. If the sintering temperature is too high or the sintering time is too long, W particle sintering neck increasing the contact area between the particles is also increasing, the formation of isolated pores, making the latter the infiltration process can not effectively penetrate the copper solution, and the obturator is formed. Such contact in the arc process appears the dregs of the phenomenon, affecting the life of the contacts. Adding activated agent and adjusting the proper sintering temperature is the most effective solution.

In addition, viewed from the cross section parallel to the pressing direction, macroscopically visible tungsten-copper material sandwiched between bright copper, microscopically observed throughout the copper belt. The appearance of micro-cracks is due to the higher speed in pressurization, and the gas in the powder is too late to escape, which has elastic after-effect after pressure relief. Secondly because the powder contained in the organic solvent is not completely evaporated, after pressing the gas slowly volatilize lead to micro cracks. The appropriate solution is to slow down the speed of pressure and ensure a longer dwell time.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater for Vacuum Coating

- Details

- Category: Tungsten Information

- Published on Friday, 03 June 2016 11:15

A vacuum is a kind of gas state whose pressure is less than atmospheric pressure. Natural vacuum is a kind of vacuum that the air pressure decreases with the increasing of altitude and present in the astrospace. Man-made vacuum is to use of a vacuum pump to draw out the gas from vacuum vessel so that the pressure of container can be lower than atmospheric pressure. Generally, vacuum coating is operating by physical vapor deposition and chemical vapor deposition methods. Normally, it can be divided into vapor deposition, sputtering and ion plating. Vacuum coating often adopts tungsten heater to evaporate aluminum. The life time of the heater is also restricted by many factors, such as the degree of vacuum, current, voltage, temperature, and the amount of aluminum and evaporation time.

A vacuum is a kind of gas state whose pressure is less than atmospheric pressure. Natural vacuum is a kind of vacuum that the air pressure decreases with the increasing of altitude and present in the astrospace. Man-made vacuum is to use of a vacuum pump to draw out the gas from vacuum vessel so that the pressure of container can be lower than atmospheric pressure. Generally, vacuum coating is operating by physical vapor deposition and chemical vapor deposition methods. Normally, it can be divided into vapor deposition, sputtering and ion plating. Vacuum coating often adopts tungsten heater to evaporate aluminum. The life time of the heater is also restricted by many factors, such as the degree of vacuum, current, voltage, temperature, and the amount of aluminum and evaporation time.

It is proved that the amount of insertion of the aluminum mandrel has a decisive role on its life time. On the premise of ensuring the plating thickness and unchanging other conditions, the amount of insertion of the aluminum mandrel should be minimized, the greater the amount of aluminum is inserted, the heater's life will be shorter. Because that there are some residuary aluminum on the tungsten heater after the completion of vapor deposition, and aluminum will react with tungsten, leading to corrosion of tungsten. As a result, with a long-term cumulative, it will greatly shorten the life of the tungsten heater.

In aluminum case of residual aluminum, the life time of tungsten heater is one-third less than those heaters which have no residual aluminum. Therefore, according to statistical data, the amount of the insertion of aluminum should be controlled within 5%~8% of the weight of the heater. Under the premise of ensuring the quality of coating, the fewer amounts of aluminum, the higher the rate of evaporation, and the degree of corrosion of the heater is also lower, therefore, life time of tungsten heater will be longer.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding For Ionization Chamber

- Details

- Category: Tungsten Information

- Published on Thursday, 02 June 2016 18:59

Ionization chamber, also known as ion chamber, is the simplest of all gas-filled radiation detectors, and is widely used to detect and measure some kinds of ionizing radiation (including X-rays, gamma rays and beta particles). It consists of different electrodes which have different potential and the dielectric between them. When the ionization chamber is under the irradiation, the rays will interact with gas molecules, and produce ion pair in the dielectric. Then these ion pairs free spread to the surrounding area to form the ionization current under the action of electric field. Since the electric current is proportional to the intensity of ionizing radiation, the intensity of ionizing radiation can be obtained by measuring the electric current. The classification of ionization chamber is extremely complex, it can be divided into treatment α ionization chamber, β ionization chamber or α and β ionization chamber, γ ionization chamber, neutron ionization chamber, electron beam ionization chamber, Bragg peak ionization chamber according to the measuring object; and can be divided into shell ionization chamber, parallel-plate ionization chamber, ionization chamber ventilation according to the shape of the ionization chamber .

Ionization chamber, also known as ion chamber, is the simplest of all gas-filled radiation detectors, and is widely used to detect and measure some kinds of ionizing radiation (including X-rays, gamma rays and beta particles). It consists of different electrodes which have different potential and the dielectric between them. When the ionization chamber is under the irradiation, the rays will interact with gas molecules, and produce ion pair in the dielectric. Then these ion pairs free spread to the surrounding area to form the ionization current under the action of electric field. Since the electric current is proportional to the intensity of ionizing radiation, the intensity of ionizing radiation can be obtained by measuring the electric current. The classification of ionization chamber is extremely complex, it can be divided into treatment α ionization chamber, β ionization chamber or α and β ionization chamber, γ ionization chamber, neutron ionization chamber, electron beam ionization chamber, Bragg peak ionization chamber according to the measuring object; and can be divided into shell ionization chamber, parallel-plate ionization chamber, ionization chamber ventilation according to the shape of the ionization chamber .

Radiation including α-rays, β-rays, neutrons, X-rays and γ-rays can cause the ionization of matter. α-ray, also known as " alpha ray ", refers to the α particle flow released from the radioactive material. Although its penetrate power is weaker than β-ray, its ionization effect is stronger that can greatly damage the human body tissues; the ionization effect of β ray is much weaker than the α-ray, but it can also damage human tissues due to its strong penetrate power; X-rays and γ-rays both have strong penetrate power and can cause harm to humans. When the body is irradiated with the radiation, radiation can restrain, damage or even kill human cells, different degrees of change in human physiology, pathology and biochemical aspects. Ionizing radiation can also cause skin damage, hematopoietic disorders, fertility damage, leukopenia, cancer, fetal death, fetal malformations and other diseases.

Tungsten alloy shielding can be used to shield radiation when using the ionization chamber to detect ionizing radiation. According to the research, the ray absorbing ability of shielding material is closely related to its density, the higher density means better shielding capability. Compared with other traditional materials (such as lead), tungsten alloy has higher density, therefore has better ray absorption capacity and shielding ability. And tungsten alloy shielding will not release toxic substances, will not endanger human health or pollute the environment.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cesium Tungsten Bronze Ultrafine Powder Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 02 June 2016 18:40

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com