Spherical Tungsten Powder Application in Cathode Substrate

- Details

- Category: Tungsten Information

- Published on Monday, 20 June 2016 17:32

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Circular Saw Blade Used for Woods Processing

- Details

- Category: Tungsten Information

- Published on Monday, 20 June 2016 16:17

Tungsten carbide materials have high hardness, high strength and excellent wear and corrosion resistance, which have been widely used in cutting tools. Especially the conventional steel circular saw blade used in woods processing has been gradually replaced by tungsten carbide circular saw blade, which has higher cutting accuracy and longer service life. Currently, tungsten carbide circular saw blade has been developing towards ultra-thin, and the swage set generally can reach 1.0mm – 2.0mm, and outer diameter typically in the range 125mm - 305mm. In addition, in the home building process as well as a variety of decorative materials processing also used by tungsten carbide circular saw blade, which can effectively improve utilization of wood, products quality, reduce energy consumption, so it has a broad application prospect.

Tungsten carbide ultra-thin circular saw blade manufacturing process includes the manufacture and heat treatment of saw plate and edges, blade geometry design, leveling blade saws, the saw blade mechanical machining, serrated welding, serrated saws and coating surface treatment technology. It has advantages as follow:

1. Small sawing width, lower cutting wastage, higher lumber recovery. Compared with conventional saw blade, it narrows 18% - 30%, the smallest ultra-thin blade edge reaches 1.0mm, which can meet the special needs of the products, such as piano keyboard, audio and so on. By reducing the cutting losses, can significantly improve the processing of sheet metal and precious materials processing timber utilization, conserve resources, improve processing efficiency;

2. Less wood crumbs by cutting, it will not cause pollution and has lower power consumption.

Currently, the main use of carbide circular saw blades in the field of wood processing in the following areas:

1. Multilayered wood flooring table board split: Use of carbide circular saw blade sawing table board will not damage the wood fibers, makes the wood natural texture, surface cracks will not appear after painting.

2. Pencil board: Early in the 1970s, American enterprises have adopted the kerf width of 1.3mm ultra-thin circular saw blades cutting board 5mm thick pencil, and introduced computers into thin blade maintenance;

3. In addition, tungsten carbide circular saw blade has been widely used in wooden shutters, piano keys, skis, audio, ping-pong racket and some other precious wood furniture manufacturing.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Material of Tungsten Heater

- Details

- Category: Tungsten Information

- Published on Monday, 20 June 2016 10:48

Due to the seventy percent of the tungsten raw material has been almost consumed, people developed a way to purify relatively poor ore. Quality of tungsten filament of tungsten heater can be affected by many factors, therefore, technicians should control and check strictly for the choice of materials and production process. For example, the production of good toughness metal powder which need to use a high purity tungsten.

Due to the seventy percent of the tungsten raw material has been almost consumed, people developed a way to purify relatively poor ore. Quality of tungsten filament of tungsten heater can be affected by many factors, therefore, technicians should control and check strictly for the choice of materials and production process. For example, the production of good toughness metal powder which need to use a high purity tungsten.

In order to prevent further growth of the grains, a small amount of volatile alkali silicates, such as thorium oxide, aluminum oxide, non volatile calcium oxide would be added into the tungsten powder. After mixing, tungsten powder is pressed into the shape of the rod, then heating it at a high sintering temperature which should be controlled at 3,000 degrees Celsius. In this step, the sintering time and temperature must be controlled strictly, and it should be operated in a closed environment, so as to ensure that the finished heater performance can be better controlled.

Under the conditions of 1300 ℃, sintering rod would be forged or beat, after passing each smaller chip, the cross-sectional area of sintering rod will be reduced five percent. Thereafter, the tungsten rods would be heated by sintering carbide filament drawing die, then it would be straighten highly polished, so as to obtain the finer heating filament. Although the electrical resistivity of tungsten is not so good as other materials, in the case of 3400 ℃, high melting point of tungsten will make it be the ideal heating material. At room temperature, the change of electrical resistivity of tungsten is small, depending on their previous treatment. Although these changes are small, the tungsten also show the similar resistivity at high temperature, this feature is very important. Due to this characteristic, heater can be mass-produced in according with a uniform voltage and current levels.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder Infiltrated with Copper-Titanium-Bismuth or Copper-Titanium-Tin

- Details

- Category: Tungsten Information

- Published on Friday, 17 June 2016 16:29

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cu Content Effect on Tungsten Copper Liner

- Details

- Category: Tungsten Information

- Published on Friday, 17 June 2016 16:02

Tungsten copper liner is considered as the heart of ammunition, which not only has high hardness, high strength and low coefficient of thermal expansion of W, but also has good plasticity and excellent thermal and electrical conductivity of Cu. Compared with single metal liner, this kind of composite liner has many advantages, such more reasonable energy conversion and absorption mechanism, fuller utilization of chemical energy, better performance in armor, lower cost, a broader application prospect and so on. With the production technology and process innovation, dense liner gradually is replaced by powder liners.

Since tungsten copper powder liner has high density, good ductility, deep penetration, less plugging and other advantages, it has been play an important role in shaped charge and some military fields. But in the process of tungsten copper liner, with the increasing temperature, Cu loss is always an inevitable problem. Cu loss will reduce the density and strength of materials. Related researchers based on pressure pressing, sintering temperature and time factors on the rate of variation of copper analyzed, and summed up the impact of copper and relative density on jet liner properties for the preparation of tungsten-copper powder liner offers theoretical basis. The experiments show that he rate of copper sintered samples with the pressing pressure increases with increasing sintering time and sintering temperature decreases, Cu loss is opposite. This is due to:

1. The pressure increases effectively narrows the distance of W grains, which reduces the Cu loss from the inside and slows internal material Cu particles outward evaporation rate;

2. The increasing pressure enlarges the contact area of Cu surface that the original Cu particles have a larger free energy in the melting process is easier and the adjacent Cu particles fuse to form larger particles. And it reduces the volatile rate of fine particles at high temperature that the content of Cu remained stable. Therefore, the content of Cu impact on the jet penetration is significant less than the relative density, but plays an important role in the stability of the jet. The smaller the rate of copper loss, the liner jet penetration is more stable.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Solar Cell

- Details

- Category: Tungsten Information

- Published on Friday, 17 June 2016 15:26

Research and application of solar cell is the focus of nowadays research on power field, how to improve the efficiency and lowering the cost are the two key problems of solar cell. The manufacturing cost of silica solar cell is too expensive which can not be widely applied. Nano TiO2 solar cell has gradually replaced the traditional one. Its manufacturing cost is only the 1/5~1/10, the photoelectric efficiency is maintained at 10%, its service life can reach 20 years. But how to promote the conversion rate is always the focus of research.

Nano tungsten oxide material has the advantages like non toxic,harmless, easy to prepare, stable property, low price and fine visible light responsive, it is an ideal semiconductor photo anode material which is widely applied in photoelectrochemical field like photo degradation water, photo degradation organic pollutant and solar cell.

Photo anode material of dye-sensitized solar cell mostly uses TiO2, the main reason is compared to ruthenium photochromics, TiO2 is the best energy level of semiconductor. Tungsten oxide is the common used photo anode catalytic material of PEC photoelectrochemical cell. Compared to TiO2 and ZnO (energy gap 3.4eV), it has smaller energy gap (2.5~2.8eV). Among which the perovskite structure will be easier to control by adjusting A and B site. So tungsten based oxide photo anode is a kind of material which has potential in photoelectrochemical solar cell anode.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

N-doped Nanoporous Tungsten Oxide Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 17 June 2016 11:38

Doping is commonly used to improve visible light responsive of transition metal oxide. A lot of researches show that metal ion like rare earth can promote the photocatalytic property of semiconductor material, however, metal doping may cause thermal stability of catalyst decreasing, it will introduce photo electron and recombination center of valance to lower its photoelectric property. Doping N can greatly improve the visible light absorption rate of semiconductor material.

Preparing of nanoporous tungsten oxide:

1) Treating method for tungsten foil: Firstly cut it into 10mm x 15mm pieces, using waterproof abrasive to polish it, then clean it with acetone, isopropanol, methyl alcohol and deionized water ultrasound cleaning for 15min, blow it with nitrogen gas.

2) Use tungsten foil as anode, Pt foil of 10 x 15mm as counter electrode, put them into electrobath, the distance between two electrodes is 25mm. Then put electrobath in water bath of constant temperature, adjust the bath temperature to control the reaction temperature. The reacting area is 0.88cm2. Adding a certain amount of ready-prepared 1mol/L(NH4)2SO4 solution electrolyte with different concentration of NH4F.

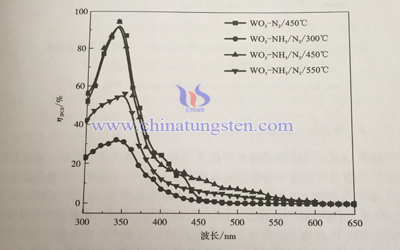

(Photoaction spectra of nanoporous WO3 photoelectrodes annealed at different temperature)

N-doping method:

Put the prepared nanoporous WO3 in tube furnace, inject NH3/N2(1:2), heat to certain temperature by heat up rate 5℃/min, keep it for a while, then cool it down to room temperature. Purity of NH3 and N2 is 99.999%, flow rate is 120ml/min.

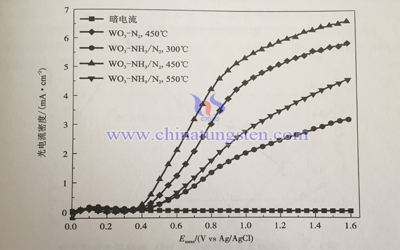

(Photocurrent density of the nanoporous WO3 photoelectrodes annealed at different temperature)

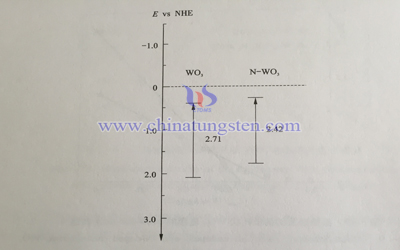

(Schematic diagram of energy band for undoped and N-doped nanoporous WO3 photoelectrodes)

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Die Status Quo

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 16:00

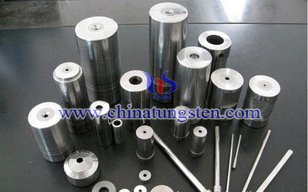

Currently, tungsten carbide material has become an indispensable role in the mold manufacturing. With the increasing complexity of the products and the higher requirement of the performance, the relevant researchers develop new carbide materials research as one of the directions. Several years ago, new carbide material mainly used Fe, Ni to replace Co, which usually used for cold heading die and cold extrusion die with high demand of toughness (such as YG15, YG20, YG25). Recent years, the hotpot turns to ultrafine grained and nano-crystalline carbide and gradient structure of cemented carbide. Fine-grained and ultrafine grain cemented carbide has been available, as YG8 fine grain carbide drawing dies in less than 1mm wire control, efficiency is three times the normal drawing die. Gradient cemented carbide is also divided into content gradient and structure gradient, they often fabricated by metal solution penetrated treatment. In addition, cast tungsten carbide heat die has a better performance in tube and wire rolling.

Based on the mechanism of tensile deformation of the metal mold uneven wear, Researchers have proposed the maximum and minimum drawing angle theory. They found that the gap between domestic and foreign mold die life lies in the angle of the design. Foreign mold at the bottom of the mold core and the mold housing bore center of the bottom-contact parts adopt double convex design, it is possible to force the center of the largest snug fit around the pore and for an interference fit. So some domestic manufactures have also been inspired, and correspondly make some improvements in the structure. Especially the improvements on the design of hexagonal carbide die, which changed into six casement combination so that it can save the consumption of tungsten carbide and convenient for assembling and changing. In terms of machining and assembling technologies, tungsten carbide usually uses hot or cold casement and vacuum brazing.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Die Description

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 15:58

Compared with conventional steel die, WC-Co tungsten carbide die has many advantages, such as high density, high hardness, high strength, low coefficient of thermal expansion, excellent wear and corrosion resistance and so on, whose service life is several times longer than the steel die. Common used tungsten carbide die grades are YG3, YG6, YG6X, YG8, YG15, YG20, YG20C, YG25, etc, and some non-magnetic alloy die materials. According to the different applications, tungsten carbide dies can be divided into tungsten carbide drawing die, cold heading die, non-magnetic die, thermal die, etc.

Tungsten carbide drawing die takes the major part and it plays an important role in metal processing by the external force is a pressure force by the metal mold, the metal cross-section is compressed so as to obtain a desired cross-sectional shape and size. Due to plastic and steel die has bad performance in wear resistance and service life, and although diamond drawing die has high hardness and wear resistance, it cost a lot. In summary, tungsten carbide drawing die has excellent properties and medium cost, which is the major part of drawing die materials; Cold heading die and stamping die are mounted on the respective use of machinery by applying a deforming force, the blank pre-formed. Carbide material hardness and excellent wear resistance, life million times in 5000-6000, the size does not substantially change, so as to effectively guarantee the dimensional accuracy of the product; No-magnetic alloy die generally used for the production of magnetic materials. Before non-magnetic tungsten carbide non-magnetic appearing, people has been using non-magnetic steel, mold its poor performance, low hardness and short life, the inner wall of the mold used for a period of time after a serious nap and deformation phenomena, so that the dimensional accuracy and surface quality of the magnetic material has been greatly affected. Non-magnetic carbide prepared by strictly controlling the carbon content and adding trace elements (Cr, Mo, Ta, NiB, Al, VC), which can replace the steel and improve the efficiency.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CsxWO3 Type Peroxide Mimic Enzyme

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 15:48

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com