Rare Earth Affected Tungsten Electrode Welding Property

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 16:07

To understand the impact of rare earth content on tungsten electrode welding property has significant for improving tungsten electrode welding performance. In the same production process, tungsten electrode with different rare earth content has different welding performance. As we all know, thorium tungsten electrodes have excellent welding performance, so as below we also compared rare earth tungsten electrode with thorium tungsten electrode.

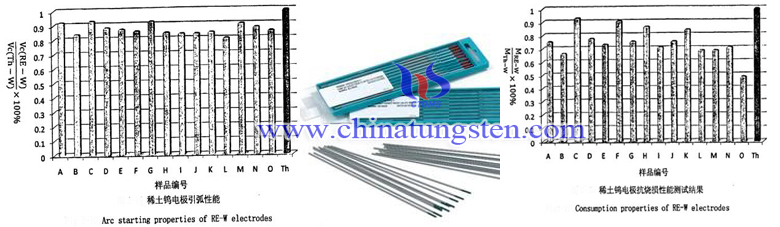

Arc Starting Property

During experiment, the cathode is water cooled brass. Besides, the arc starting experiment starts form 30V and each interval increases by 1V no-load voltage. To carry out 30 times arc starting experiment for each voltage, the arc starting worked within 1 second is supposed to success and within 1 ~ 10 refers to arc starting lag behind, more than 10 seconds to arc which is failure. Learned form the experimental data shows that the rare earth tungsten electrode arc starting performance is better than thorium tungsten electrode. Rare earth tungsten electrode has low work function, so it has good arc performance. Doped with a variety of rare earth composite rare earth tungsten electrode arc starting property is superior to rare earth tungsten electrode doped with single rare earth oxide. Yttrium tungsten electrode high yttria content has better arc performance.

Anti-burning Performance

In experiment, the tungsten electrode links to the negative electrode, at 250A welding current arcing for 30 minutes. And then to use DP-100 optical analytical balance measured the electrode mass change before and after the experiment. From the experimental data shows that the mass of rare earth tungsten electrodes is higher than thorium tungsten electrode, namely, rare earth tungsten electrode has better anti-burning property than thorium tungsten electrode. Among different rare earth tungsten electrodes, yttrium tungsten electrode exhibits more excellent anti-burning property. When other conditions being equal, the lower work function on electrode surface is lower, the lower operating temperature, and anti-burning property is better. Rare earth tungsten electrode formed low work function active layer on the surface, so the anti-burning performance of the RE tungsten electrode is relatively good.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Iron, Cobalt and Tungsten Mixed OER Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 16:01

Researchers at the University of Toronto in Canada and Stanford University in the US say that they have made the best oxygen-evolving reaction (OER) catalysts to date. The new catalysts, which are made from gelled multimetal oxy-hydroxides, have nanoporous structures and large specific surface areas containing lots of active sites for electrolytic reactions like the OER. The oxy-hydroxides can be prepared in a simple room-temperature process, which means that they might readily be scaled up to industrially relevant volumes.

The OER is one of the main processes occurring in metal-air batteries, solar water splitting and solar-powered fuel cells in general. It can be used to produce oxygen from water and as such could be a clean and renewable way to generate energy. Unfortunately, the reaction is rather slow and researchers are trying to find efficient catalyst materials to help speed it up. Although oxides based on ruthenium and iridium are good in this respect, these metals are expensive, which means they cannot realistically be used to make devices on the large scale.

Researchers say they have now discovered a new class of efficient catalyst for the OER based on the metals iron, cobalt and tungsten mixed together homogenously in an oxy-hydroxide framework that do have a nanoporous structure with large numbers of electrochemically active sites. The gelled multimetal structures can also be prepared via a simple room-temperature process, so they could easily be produced in large quantities.

The team began by dissolving precursors for all the metals in a polar organic solvent to form a homogenous solution. "By choosing suitable reagents, auxiliary agents and reaction conditions, we coordinated the hydrolysis of the different metal precursors, such that they were programmed to occur at similar rates to one another," explains Sargent. "This approach allowed different metal oxy-hydroxides to form simultaneously in an atomically homogenous distribution. Combining the metals in this way is challenging, since metals and metal oxides tend to phase-separate in crystalline oxides."

"Using state-of-the-art computational tools and powerful computers, we were able to understand, on the atomic scale, why and how the multimetal component oxide works," explains Vojvodic. "For example, an active site, where the OER takes place, containing cobalt, iron and, importantly, tungsten was found to be crucial."

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Nanostructures for Solar Energy Conversion

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 15:57

Photoelectrochemical water splitting, where irradiation of a photoelectrode in water produces hydrogen and oxygen, can be used for solar energy harvesting and conversion. The process potentially offers a clean, sustainable, and large-scale energy resource. Photoanodes used in the photoelectrochemical process are generally made from Earth-abundant oxide semiconductors, such as titanium dioxide, tungsten trioxide, and iron (III) oxide. Among these metal oxide semiconductors, tungsten trioxide is regarded as one of the best candidates because of its visible light-driven photocatalytic activity, its good charge transport properties, and its relative stability in aqueous electrolytes. However, the light absorption and charge collection efficiency of tungsten trioxide—especially within a bulk structure—still needs to be improved to realize practical photoelectrochemical applications.

To further improve the transport efficiency of tungsten trioxide (and other semiconductors), low-dimensional structures have specifically been identified as offering direct electrical pathways for photogenerated carriers. These structures feature reduced grain boundaries that enable superior charge transport efficiency. The synthesis of low-dimensional semiconductor nanoarchitectures by low-cost synthetic procedures (e.g., a hydrothermal approach) is therefore a promising method for future large-scale implementation of photoelectrochemical water splitting and clean energy production. In particular, the morphologies and structures of catalysts are important parameters in photoelectrochemical applications. Tungsten trioxide thin films with various morphologies have previously been reported, and are widely used in electrochromic, field-emission, gas-sensing, and photoelectrochemical water-splitting devices.

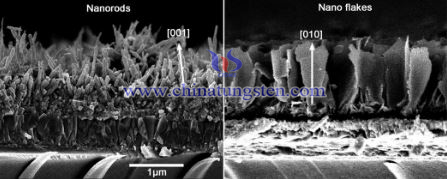

(Arrays of tungsten trioxide nanorods (left) and nanoflakes (right) that were grown on fluorine-doped tin oxide-coated glass, through the use of a solvothermal technique. )

In our recent work we have therefore focused on hydrothermal synthesis of low-dimensional tungsten trioxide nanostructures for photoelectrochemical applications. We have developed a simple method for the deposition of ordered arrays of tungsten trioxide nanowires and nanoflakes on fluorine-doped tin oxide (FTO)-coated glass. In this approach, we use a solvothermal technique, which involves the crystallization of a solution at high temperature and pressure. To demonstrate this technique, we used a tungsten trioxide seed layer to initiate growth and we tailored the geometries by adjusting the composition of the hydrothermal precursor. We can grow hexagonal tungsten trioxide nanowire and monoclinic nanoflake arrays in the or crystallographic directions, and we can tailor the wires and arrays by adjusting the solution composition. After the annealing process, we found that the samples exhibited further reductions in their band gaps, which improved the photocurrents significantly. We attribute this change in electronic band gap to the distortion of the tungsten trioxide crystal structure's octahedral building blocks, which occurs during annealing. Our solvothermal film growth technique is thus an exciting development for the fabrication of 1D metal oxide nanostructures that may enable practical applications in photoelectrochemical energy conversion.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Impurities in Tungsten Carbide Process

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 15:04

Except external impurities, the impurity in tungsten carbide manufacturing process is also one of the important reasons. According to different forming agent types, the impurities of forming agent can be divided into rubber type and paraffin type. The main reasons of rubber forming agent includes two aspects, one is rubber dissolved in gasoline the gel formed caused by low solubility. Gel molecules are generally smaller, higher ductility, insufficient pressure in pressing process, can not be sufficiently deformed, easy to form pores after sintering shrinkage; the other is inorganic fillers used in the rubber production process remains in forming agent system introduced metallic impurities. Thus it needs to choose lower content of calcium sulfate or appropriate to add a thermoplastic rubber monomer and polymer resin to reduce the amount of rubber. In the sintering process, paraffin forming agent will directly volatile because of the lower melting point, which has been widely used in tungsten carbide manufacturing. But in practical applications, paraffin emulsion easily precipitate formed from ethane. It has bad performance in tungsten carbide powder cladding and form holes after sintering shrinkage. For this problem, the researchers impels the powder surface modification by organic phase cladding carbide powder such as stearic acid, resin acids, etc., in order to promote the compatibility of the entire system.

In the sintering process, with the increasing sintering temperature, Co binder phase will be in a molten state, due to the different degree of shrinkage in the cooling process, Co phase aggregation can occur during shrinking process and holes appear in tungsten skeleton. Therefore, relevant researchers improve the vacuum sintering process and make sintering and pressing in the same device, so that it is not likely to cause the product oxidation and decarbonization. In addition, there are many new processes, such as auxiliary field sintering process, gradient sintering process and laser sintering process, etc, which promote the matrix densification by reducing the amount of cobalt pool and improving the surface quality of powder.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy And Nuclear Radiation Protection

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 15:03

With the development of China's modernization, the application of radioactive substances and nuclear radiation technology has been developing rapidly. Nuclear radiation, or commonly referred to radioactivity, is the micro-particles released by nucleus from the conversion process of an energy state or a structure into another structure or another energy state. Currently nuclear radiation sources have been widely used in industrial, medical, scientific research, agriculture and other fields, such as for the flaw inspection of petroleum pipeline transportation and large machines and food sterilization and preservation. Although the application and research of nuclear energy has brought country and people huge benefits, but its harm also should not be underestimated.

With the development of China's modernization, the application of radioactive substances and nuclear radiation technology has been developing rapidly. Nuclear radiation, or commonly referred to radioactivity, is the micro-particles released by nucleus from the conversion process of an energy state or a structure into another structure or another energy state. Currently nuclear radiation sources have been widely used in industrial, medical, scientific research, agriculture and other fields, such as for the flaw inspection of petroleum pipeline transportation and large machines and food sterilization and preservation. Although the application and research of nuclear energy has brought country and people huge benefits, but its harm also should not be underestimated.

Nuclear radiation has harmful effects on the human body, once the body is irradiated with the nuclear radiation, it can cause nausea, vomiting, spontaneous bleeding, dizziness, insomnia, skin redness, ulcers, bloody diarrhea, skin peeling, hair loss, severe fatigue, gastrointestinal disorders and other symptoms, in severe cases it can even cause nerve cells, gastrointestinal cells and immune system damage. Due to the nuclear radiation will block the metabolism of cells, a large number of cells will grow, which can also lead to lung cancer, leukemia, thyroid cancer, breast cancer and other cancers. Sometimes nuclear radiation will increase distortion, the incidence of hereditary disease, affecting the health of generations. In general, the more radiation energy received by the body, the greater the risk of cancer, birth defects will be.

Tungsten alloy can be used for nuclear radiation protection due to its high radiation shielding performance. Compared with the traditional shielding materials (such as lead), tungsten alloy shielding has higher density, thus in the condition of the same weight, the volume of tungsten alloy shielding is smaller, but its radiation shielding performance is not diminished. Further, lead shielding is toxic which can harm human health and pollute the environment, while the problem does not exist in the tungsten alloy shielding.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Analysis of Tungsten Carbide External Impurities

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 15:01

In the process of tungsten carbide manufacturing, it is significant that to control the number and size of internal holes. Too large or too much pores will remarkably accelerate the fracture and speed of tungsten carbide products, which also decrease the strength and toughness of overall alloys. So to study and analyze tungsten carbide impurities plays an important role in improving tungsten carbide process. Analyze through experiments and based on the actual production process, there are many causes of tungsten carbide external impurities, such as impurities in the air, metal impurities, oxide particles impurities and so on.

Since long tungsten carbide manufacturing process, the introduction of external impurities channels is multi-faceted, such as dust in the air, human hair, etc, which is likely to introduce impurities from mixing, sintering, stored in the transport and other processes. These impurities are largest in number after sintering is also often difficult to remove effectively in a subsequent step. In order to solve this problem requires the operator to strictly abide by the rules, to minimize the human factor introduced by the impurities; secondly, as far as possible it should be fully enclosed production lines and hot isostatic pressing (HIP) method to reduce the dust in production workshop.

The introduction of metal impurities is mainly caused by the equipment used in the production of cemented carbide, such as mesh sieve granulation rub broken when it been used; ball milling cylinder wall is rubbed crumbs mixed with metal powder; some debris and equipment due to corrosion, aging and other factors may cause the introduction of cemented carbide impurities. Most of the metal impurities are lower than the melting point of carbide materials and carbide and impurities has different degree of shrinkage, so In the sintering process will first melt and penetrate into the edge of the cemented carbide powder particles, and the binder phase Co compromised; adhesion and wettability deteriorated; edge adverse tissue contraction, resulting the hole. Thus we should pay attention to the screen usage, comply with operating procedures and regularly inspect the equipment corrosion, aging phenomenon.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Operating Procedure of Tungsten Heater for Aluminum Plating Machine - Tungsten Wire Installation

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 11:42

Tungsten heater has a high melting point and high corrosion resistance, so it is widely used in vacuum aluminizing industry. Aluminum plating machine is to use electron beam to heat evaporation material which is going to be heated under vacuum, and then the material would evaporate and condenses to form the film. Operators should pay attention to some details when the tungsten wire is being installed.

Tungsten wire should be placed in parallel, and the screw should be locked-in without any loosen, under (if heating in the case of non-parallel of tungsten, after the aluminum melt, it flow to the high, leading to the splashing or crystalline of tungsten cannot be used. And the fastening screws will cause evaporation current instability, leading to splash, or blown tungsten heater). When placing molybdenum wire, openings of it should be tighten up a little inclined, (the incline is to avoid dealuminizing of abscission of material when magnesium fluoride is put in the molybdenum wire). The tin board should be new, clean, smooth, and without ant tilt at the hem, (after using, tinfoil would change color, and the electric shock part is lackluster, if it is still to be used, which cannot achieve the effect of ion bombardment, resulting in workpiece cannot absorb aluminum and influence the dealuminizing, tin board with folding would affect ion bombardment).

When install the hanger, screws should be tighten so that the hanger would not drop to influence aluminizing when the machine is turning. Do not touch the aluminized side of workpiece when placed on the it (to avoid producing yellow or black artifacts after aluminizing because of fingerprints, oil of gloves and sweat. Even if there is no such phenomenon, it will also affect the dealuminizing). The workpiece placed on the hanger should be tighten so as not to fall off and affect aluminizing or scratch other artifacts.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Operating Procedure of Tungsten Heater for Aluminum Plating Machine - Power Control

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 11:39

Tungsten heater is used as a heating element in aluminum plating machine for aluminum film. Aluminum machine operation begins with the power supply.

Firstly, open power supply, turn on each cycle valve, cooling vacuum system, and open the maintain pump to pre-vacuum pumping for diffusion pump for 30 minutes, heated diffusion pump about 1 hour and vacuum aluminizing.

Cleaning up the operation vehicle, and then placing tungsten heater, molybdenum wire magnesium fluoride, two tin board, and put aluminum workpieces. Put the operation vehicle into the room, close the door, and open mechanical pump. 5-7 seconds later, open the pre-pumping valve F2, open composite vacuum gauges, there are two screens of high and low vacuum, on the vacuum gauge. When the low vacuum gauge displays 4.0E-0, close pre-pumping valve F2, pre-opening valve F3, and open the high vacuum valve F1. When the high vacuum valve shows 4.0E-2, open the work vehicle, and adjust the voltage in the 50V-70V. After the rotation is normal, open FK3 valve flow indicator, turn off a high vacuum flapper valve, and control high vacuum table. When it shows 4.0E-0, open bombardment power and adjust voltage between 800V-1200V to clean ion for 5 minutes. Turn off the bombardment power and rotated power, FK3 valve. Close flow indicator, open high vacuum baffle valve for creation of vacuum. After high vacuum table shows 2.0E-2, it is time to vacuum aluminizing.

If the time for vacuum aluminizing stay for too long, it would cause that the tungsten wire would direct baked aluminum layer of tungsten surface, and then it would be oxidation and become yellow. The quality of aluminum film also influenced by the quality of vacuum, the stable process parameters, subsidiary materials for aluminizing, the storage time of aluminizing workpiece. If the cleaning of coated article is not complete, its surface would have residual cleaning agents and water.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Radiation Protection Window

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 June 2016 19:02

With the development of science and technology, radiation technology has been widely used in biological research, medicine, industry and agriculture. In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or through a material medium. It can be divided into ionizing radiation and non-ionizing radiation depending on its energy level and its ability to ionize substances. The word “radiation” generally refers to ionizing radiation. Ionizing radiation are mainly α, β and γ radiation three kinds. Beta-ray is a stream of electrons which moves at high-speed and has strong penetrating power; alpha particles consist of two protons and two neutrons bound together into a particle identical to a helium nucleus; γ-ray, also known as the stream of γ particles, is released by nuclear energy level transition, and its wavelength is shorter than 0.01 Å. γ-ray can be used in the industry for industrial flaw detection or automatic control of the pipeline.

With the development of science and technology, radiation technology has been widely used in biological research, medicine, industry and agriculture. In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or through a material medium. It can be divided into ionizing radiation and non-ionizing radiation depending on its energy level and its ability to ionize substances. The word “radiation” generally refers to ionizing radiation. Ionizing radiation are mainly α, β and γ radiation three kinds. Beta-ray is a stream of electrons which moves at high-speed and has strong penetrating power; alpha particles consist of two protons and two neutrons bound together into a particle identical to a helium nucleus; γ-ray, also known as the stream of γ particles, is released by nuclear energy level transition, and its wavelength is shorter than 0.01 Å. γ-ray can be used in the industry for industrial flaw detection or automatic control of the pipeline.

Although radiation brings a lot of convenience to people's lives, but its hazards also need to be valued. Such as γ-ray has a strong penetration power. When the body is exposed to γ rays, γ-rays can enter into the interior of the human body and interact with the cells in vivo, to corrode the complex organic molecules (such as proteins, nucleic acids and enzymes), and thus interfere with the normal chemical processes in the human body, and even cause cell death. In addition, ionizing radiation can alter the chemical balance of the cell (sometimes cause cancer) and damage the genetic material in the cells in the body, leading to fetal malformation and congenital leukemia. So the installation of tungsten alloy radiation protection window in radioactive laboratories and other places which can release radiation is necessary.

Tungsten alloy radiation protection window is made up of tungsten heavy alloy with high-density. According to the research, the radiation shielding properties of a metal material increases with its density. Compared with other traditional materials (such as lead), tungsten alloy has higher density, thus it has greater radiation shielding performance to avoid radiation damage.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

High Density Composite Material Containing Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 June 2016 17:44

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com