Tungsten Powder and Bronze Composite Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 17:58

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Deep Cryogenic Treatment Effect on Tungsten Carbide Materials

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 15:51

First of all, viewed from micro structure, deep cryogenic treatment has no obvious effect on the WC granularity, contiguity, and γ phase mean free path of tungsten carbide materials. Carbide without cryogenic treatment contains only a small amount of brittle η phases, by comparison, after the cryogenic treatment due to carbide long-term exposure to extreme temperatures and η phase increases. There are some experiments found that after deep cryogenic treatment, tungsten carbide has more uniform distribution, the binder Co and hard phase WC combined firmer and the overall wear resistance is significantly improved. Furthermore, the deep cryogenic treatment temperature provides greater two-phase free energy difference (High-temperature phase α-Co (fcc structure) and Low temperature phase Σ-Co (hcp structure)). At such low temperature, the atomic diffusion capacity reduced and formed no-diffusion phase transition process. In the research of deep cryogenic treatment of TW carbide inserts, we can found that the blade without deep cryogenic treatment has both of Σ-Co phase andα-Co phase, while the blade after treatment only hasΣ-Co phase. It indicates that after deep cryogenic treatment, Co of TW has a complete martensitic transformation. Overall, deep cryogenic treatment can promote binder Co transfer fcc structure to hcp structure.

Due to the great difference of the coefficient of thermal expansion and linear expansion coefficient between WC and Co phases of tungsten carbide, tungsten carbide has large thermal stress inside after cooling. And WC phase is subjected to compression stress, Co phase is subjected to tensile stress. By cryogenic treatment can make the carbide obtained two-phase thermal stress relaxation, thereby increasing the strength of carbide cutting tools. In addition, in mechanical properties, carbide cutting tools after deep cryogenic treatment, the hardness has greatly improved (from HRA90 to improve HRA92, HV1764 increased to HV2263.7). While YG6X, YG8, YG10C, YT14 four grades after deep cryogenic treatment, Various grades of alloy coercive force has been significantly improved, significantly lower than the saturation magnetization, has improved hardness, density substantially constant and flexural strength dramatically.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Materials Deep Cryogenic Treatment

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 15:50

Conventional heat treatment is an important technology to improve the structure and properties of materials. And deep cryogenic treatment is a kind of new technology that develops and extends on this basis. For common steel materials, deep cryogenic treatment has many advantages, such as:

1. It can make the retained transferred, improve the hardness of the workpiece and keep the dimensions stable;

2. The precipitated ultra-fine carbides can remarkably improve the wear resistance of workpieces;

3. It can effectively refine the grains and improve the impact toughness of the workpiece;

4. It can improve the corrosion resistance of Martensitic stainless steel and the polishing properties and so on.

In addition, with the further development of liquid nitrogen cooling and insulation technology, deep cryogenic treatment has been gradually widely used in tungsten carbide materials fields.

At present, the studies of tungsten carbide material deep cryogenic treatment can be mainly divided into two types: one is contains cooling and holding two stages, which control carbide cooling from room temperature to the processing temperature. In this process, it should be noticed that the controlling of the cooling rate in case of a greater thermal shock. And then hold a day or longer at deep cryogenic treatment temperature; the other one is with tempering treatment and control the temperature rise above ambient temperature and maintained for some time. The experiment shows that the cutting force of tungsten carbide blade has been reduced, the thermal conductivity has been improved, the wear loss of blade was smaller, the surface toughness was higher and the service life has been extended. But in the state of continuous cutting, the effect of deep cryogenic treatment will disappear with the increasing cutting time. This is due to the carbide tool cryogenic treated in a metastable state, the role of the cutting tool after high temperature cryogenic treatment a long time will gradually decrease until it disappears. So in order to extend the effect of deep cryogenic treatment, we can add some cooling medium from outside.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder and Non-Lead Hollow Point Bullets

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 July 2016 17:53

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Molding Pressure Effect on Tungsten Copper Composite Materials

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 July 2016 14:52

Except powder granularity, the molding pressure is also one of main influencing factors of tungsten copper composite materials density. The experiments show that with the increasing molding pressure, the density of sintered blank is increasing. On the one hand, it due to the increasing pressure promotes the densification in the third stage of the compaction, that is when the pressure exceeds a certain value continues to increase, if it continues to increase pressure on the powder by the pressing force and the frictional force is greater than the elastic stress. Particles have plastic deformation and fill in the gap of powder, which will further increase the density; on the other hand, due to nano-crystalline copper particles themselves have a very large surface free energy, if the pressing pressure is further increased, the copper particles are plastically deformed again, i.e., the copper particle surface free energy is further increased to further reduce the melting point, which make it infiltrate tungsten particle at low temperature and promote the densification process.

In addition, it is inevitable that copper evaporation in the process of tungsten copper manufacturing. The researcher found that when the particle size of Cu grain reaches nano scale, it will be volatile at 450℃. So under the optimum holding temperature of 1350℃, Cu phase will be easily consumed by evaporation. since tungsten copper material is a versatile material, after copper volatile, not only because of the disappearance of the binder phase becomes loose, reduce the density and strength of the material, it will make the physical as well as electrical and thermal conductivity coefficient of linear expansion and other materials significant performance degradation. There is an experiment uses two kinds of pressure 300MPa and 800MPa pressed found that with the increase of molding pressure, the material density increased wettability of liquid copper has been significantly improved, while the loss of copper in the case of the high temperature phase has also been in control. This is due to:

1. Increasing molding temperature reduces the spacing of W grains and improves the strength of W skeleton, which also make it difficult to form a copper material inside the material loss of external channels, slow volatile speed of copper particles within the material;

2. Large molding pressure increases the surface contact area of the copper, so that the original surface free energy with increase in the melting process of the copper particles and copper particles easier contact between adjacent and fused together to form larger particles, thereby reducing the fine particles volatile chance of high temperature phase, maintaining the stability of copper content.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Powder Granularity Effect on Tungsten Copper Composite Materials

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 July 2016 14:50

Tungsten copper composite materials not only have advantages of W, such as high hardness, high strength, high density, low coefficient of thermal expansion and excellent wear and corrosion resistance, but also have good plasticity and excellent thermal and electrical conductivity of Cu, which have been widely used in electronic industry, high-temperature resistant devices fields. But there is a big difference in melting point and physical properties between W and Cu, and they are immiscible. So it makes tungsten copper composite material preparation process simpler, commonly used PM (Powder Metallurgy) process, which limits the rang of applications. Therefore, we through analyzing powder granularity effect on the density of tungsten copper composite materials, optimizing the sintering process, the properties will be further promoted.

Take mass ratio of 85% of tungsten copper composite material manufacture as example, the particle size of not more than 1.0μm nano-crystalline copper with particle size of not more than 0.8μm nano-crystalline tungsten powder mass ratio of 85:15 were mixed in a ball mill planetary, milling medium is ethanol. After ball milling, take powder and dried in a vacuum glove box under Ar protection; after drying, pressed and vacuum sintered. Viewed from SEM image, with increasing milling time, the granularity of powder reduced and the degree of mixing and mechanical alloying of the number of particles has been significantly increased. Although tungsten particle has high hardness, sharp edge portion is worn continuously, and shape gradually becomes more regular ball; Copper particles are constantly impact occurs between the ball, the tank and the tungsten particles, grinding and tearing, particle size becomes smaller. So the mutual attraction between particles become greater, the rearrangement faster. In addition, small powder size, large surface area, surface activity and lattice activity also increased, which is beneficial for sintering process and improving the density and structure of tungsten copper composite materials.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide in Inverted Polymer Solar Cell

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 18:19

Interest in solar cells to capture sunlight and generate electricity is increasing due to oil energy crisis and rising concerns over global climate change. Inorganic solar cells can yield high power conversion efficiency but the expensive fabrication process makes them infeasible in common use. Instead, polymer solar cells PSCs are a good candidate because semiconducting polymers can be dissolved in common solvents and printed like inks so that economical roll-in-roll fabrication process can be realized. The photoactive layer composed of electron donating and accepting materials absorbs light and generates excitons. Then electrons and holes can be efficiently separated from each other due to the nanometer-scale interpenetrating network of electron donor and acceptor within the whole photoactive layer.3 However, a simple structure that sandwiched the photoactive layer between two electrodes anode and cathode is not perfect enough. The low efficiency of charge collection at the interface between the photoactive layer and electrodes results in poor performance of PSCs.4 In order to solve this problem, interfacial layers, such as a combination of poly-ethylenedioxythiophene: polystyrenesulfonate and lithium fluoride LiF, are commonly introduced between the active layer and electrodes to improve charge carrier collection and to enhance the open-circuit voltage.

Nevertheless, PEDOT: PSS has been demonstrated to have a side effect on the performance of PSCs due to its corrosion to indium tin oxide ITO and electrical inhomogeneities. In order to overcome this problem, one might simply introduce interfacial layer materials to improve the performance of PSCs. Recently, molybdenum oxide MoO3, vanadium oxide V2O5, and nickel oxide NiO have been demonstrated to effectively substitute PEDOT:PSS as the anodic buffer layer in PSCs. An alternative approach is to reverse the device architecture and hence to form inverted PSCs, in which MoO3 and V2O5 were usually inserted between the active layer and top electrode.

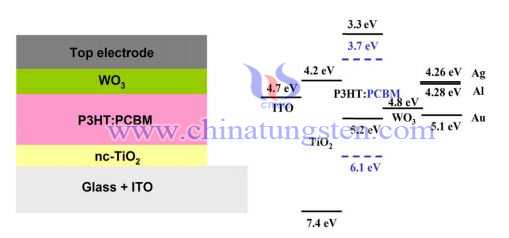

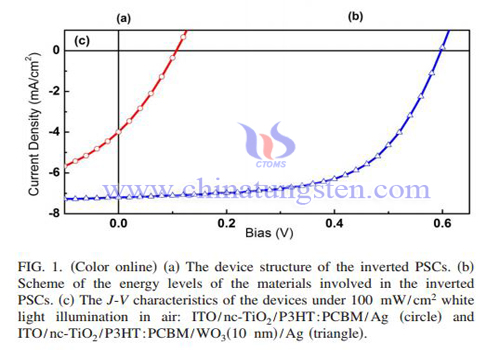

In this letter, we introduce a low-cost, nontoxitoxic, and easily evaporable tungsten oxide WO3 as a hole extraction layer in inverted PSCs with nano crystalline titanium dioxide nc-TiO2 as an electron selective layer. The device architecture is shown schematically in Fig. 1 a. and the energy level diagrams of different materials used in the device fabrication are shown in Fig. 1b. Meanwhile, transparent inverted PSCs are fabricated with thermally evaporable Ag13 nm/WO340 nm as a transparent anode when introducing a 10 nm WO3 buffer layer. After a cleaning step, TiO2-sol was spin coated on ITO-coated glass substrates at 3000 rpm. Then the samples were moved to a muffle furnace and annealed at 450 °C for 2 h. After annealing treatment, nc-TiO2 was formed. In this letter, poly3-hexylthiophene P3HT Rieke Metals was used as electron donor material, and -phenyl C61 butyric acid methyl ester PCBM Solenne BV was used as electron acceptor material. The mixed chlorobenzene solution composing of P3HT 10 mg/ml and PCBM 8 mg/ml was then spin coated on top of the nc-TiO2 layer at 700 rpm in ambient air. Then the samples were heated in low vacuum oven at approximately 150 °C for 10 min. Subsequently, the samples were pumped down in vacuum 10−3 Pa. Finally WO3 and 60 nm top electrode Ag, Au, and Al were thermally evaporated in sequence. The active area of the device was about 0.064 cm2 .

In summary, we have explored the use of WO3 in inverted polymer solar cells. Due to the high work function 4.8 eV, WO3 efficiently extracts holes and suppresses electrons from the active layer. The thicknesses of WO3 and different top metal electrodes on device performances are also investigated. Transparent inverted PSCs are fabricated with Ag13 nm/WO3 40 nm as a transparent top electrode when introducing a 10 nm WO3 buffer layer, which have the potential to realize a multiple device structure to absorb more solar photons by the multiple photoactive layers to achieve high device performance.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder and Acoustic Sensor

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 17:42

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Photocatalyst for Ocean Oil Pollution Treatment

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 17:38

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Hob Description

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 15:39

Tungsten carbide hob is composed of the hard phase WC and the binder phase Co, its edges helically arranged along cylinder or cone to manufacture cutting tools, which has been widely used in cylindrical gears, worm and other toothed cylindrical workpieces fabricating. According to different applications, tungsten carbide hob can be specifically divided into gear hobs, worm hobs, fixed mounted hobs, non-involute hobs and so on. Compared with common high-speed steel hobs, tungsten carbide hobs have better performance in cutting rate and button efficiency. Solid tungsten carbide hob has been widely used in watches and some of the precision instrument manufacturing industry, such as processing a variety of small module gear; medium modulus solid carbide hob and panels have been used for machining cast iron and bakelite gear; modulus < 3 tungsten carbide hob is also used in steel gear manufacturing; in addition, tungsten carbide hob is also can be used for fabricating hardened wheel (HRC50-62).

Tungsten carbide worm hob is a kind of special tool for worm manufacturing. Its main transmission type and basic parameters of the worm (including module, pressure angle, helix angle, pitch diameter, number of thread, etc.) should work with the same worm. When the worm is large in outer diameter, shaft-mounted hob can be made; when the worm is small in outer diameter, the hob can be made integral with the mandrel shank-type structure. Tungsten carbide fixed mounted hob has different profiles, which only the last one button is the precise button. Gullet button and forming a workpiece identical to alveolar milling method of cutting a workpiece, the rest of the button are for rough cutting and the movements is as same as the gear hob. In addition, forming hob can effectively avoid the exhibition to the transition curve tooling generated the root, especially the ratchet hob. The mechanism of non-involute hob is similar to the gear hob, such as spline hob can be used for processing rectangular teeth, involute or triangular tooth spline shaft, which has better machining precision and efficiency than forming cutters. And it also can be used for arc gears, cycloid gears and sprockets manufacturing.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com