Choice of Heater for Vacuum Coating - Tungsten Heater

- Details

- Category: Tungsten Information

- Published on Friday, 08 July 2016 16:12

Vacuum coating is a sophisticated technique for the application of modern new technology, and it is also an important topic of applications and research for “modern physics experiment” of institutions higher learning. As for experimental teaching, the traditional approach is to use refractory metal—— tungsten, which has the highest melting point (3380℃) and molybdenum with the melting point of 2620 ℃ as a heating element. Plated metal is generally used lower melting point metals such as silver (melting point 960℃) and gold (melting point of 1063℃). In order to ensure the quality of coating, operators usually use high-purity gold and silver, but gold and silver need to go through a public purchase of the public security department for approval, so the price is very expensive. Therefore, in the choice of the coating material, it needs to consider all aspects of the problem.

Vacuum coating is a sophisticated technique for the application of modern new technology, and it is also an important topic of applications and research for “modern physics experiment” of institutions higher learning. As for experimental teaching, the traditional approach is to use refractory metal—— tungsten, which has the highest melting point (3380℃) and molybdenum with the melting point of 2620 ℃ as a heating element. Plated metal is generally used lower melting point metals such as silver (melting point 960℃) and gold (melting point of 1063℃). In order to ensure the quality of coating, operators usually use high-purity gold and silver, but gold and silver need to go through a public purchase of the public security department for approval, so the price is very expensive. Therefore, in the choice of the coating material, it needs to consider all aspects of the problem.

Tungsten and molybdenum are refractory metal, and both of them have high temperature strength and excellent acid corrosion ability, which are an important material for military industry and the chemical industry. However, there are two issues that must be taken into account that “cold brittleness” of tungsten and molybdenum and they would act with the surrounding gas vehemently at high temperatures. Because of these two problems, these greatly limit the tungsten heater aluminized applications.

Thus, vacuum coating must note the followings:

1. The choice of heater material and the coated metals..

2. Maximize the degree of vacuum coating chamber (1 × 10-4mmHG ~ 1 × 10-5mmHG).

3. Coating chamber must be baked for a long time before coating the (30 to 45 minutes).

4. Using bombardment rod to bombard at low vacuum for a long time (20 to 30 minutes), these measures are to clean up miscellaneous ions and other gas molecules in coating chamber.

5. Control the preheat temperature and coating time to achieve the desired coating.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Fiber Cutter — Laser Cladding

- Details

- Category: Tungsten Information

- Published on Friday, 08 July 2016 15:35

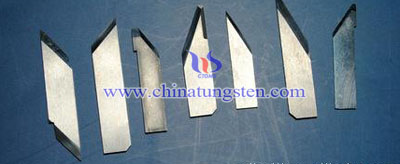

Tungsten carbide fiber cutter has been widely used in textile and chemical fiber industry because of its excellent properties. But the cutter will be easily wore in a long time of cutting fiber process. So usually high-performance solid carbide sintering or overall high-speed steel required by carburizing, nitriding, carbon-nitriding and other chemical treatment methods to be prepared. The complicated process and higher cost are the main factors of impeding the developments of tungsten carbide fiber cutter. After many studies and experiments, the relevant researchers developed a new kind of surface treatment with a broad prospect — laser cladding. It takes tungsten carbide materials as high-performance cladding layer and forms a strong metallurgical bond with the base materials. Laser cladding process is essentially a rapid heating and rapid cooling and solidification of the melt process, deviation from the equilibrium state, the cladding structure refinement, hardness, strength and wear and corrosion resistance and other aspects of the process significantly better than other methods.

The researchers try to introduce laser cladding process into the manufacturing process of tungsten carbide fiber cutter. It laser cladding tungsten carbide layer in the edge portion of the cutter, which not only organically combines the excellent toughness and manufacturability of the metal base with the excellent wear, corrosion resistance and chemical stability, but also effectively improves the hardness and wear resistance of the edge of fiber cutter and extends the service life, reduces the production costs. In the process of cladding, first sample in an oven at 200 ℃ drying 4h, the selection of the bath as nitrogen protective gas laser beam synchronized blowing protection. After cladding with a prepared solution complete with pre-grinding and polishing good corrosion samples, metallurgical microstructure observed. In addition, mainly due to the generation of holes WC carbide laser cladding layer is WC dissolution and decomposition of the generation of holes provide a carbon source. At the same time, Co very prone to oxidation, causing intense gasification reaction, and the gas formed too late to escape will result in the appearance of pores. And adding an appropriate amount of Al powder can effectively inhibit the generation of holes, or TiC powder can be added to improve the hardness of cladding layer to meet the requirements of tungsten carbide fiber cutter properties.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Fiber Cutter

- Details

- Category: Tungsten Information

- Published on Friday, 08 July 2016 15:32

In the textile and chemical fiber industry, in order to blend chemical fiber cotton and other natural fibers, the continuous fiber tow after dragging, crimping and heat setting treatment needs to be cut into predetermined length by fiber cutters. In the cutting process, with the increasing using time, the properties of cutter will gradually reduce until passivated, which has an effect on the quality and efficiency of fiber cutting directly. Tungsten carbide fiber cutter has many advantages, such as high hardness, high strength, high impact toughness and excellent wear and corrosion resistance, which are beneficial for the practical applications of textile and fiber industry. Fiber cutting depends on the contacting movements between the cutter and the tow, which essentially cutter pushes the fiber to produce deformation and fracture.

In general, the materials used for fiber cutter include tool steel, high-speed steel, tungsten carbide and so on. Tool steel requires several sharpening during the process, frequent tool change will result in cutting quality fiber product instability, labor-intensive, low productivity, now gradually being eliminated; there are some highly dispersed and stable VC hard particles in the high-speed steel organization. Dispersion strengthening improves the hardness of the matrix and the stable VC hard particles greatly improve the wear resistance of the materials. In addition, adding some Si and Al elements in high-speed steel can effectively improve the hardness and wear resistance, and adding Nb element will be reacted with C to generate diffused fine NbC, which can effectively prevent the grain growth; super hard high-speed steel and tungsten carbide materials are composed of W, Mo, Co and other rare metals, which have excellent cutting performance and longer service life. But they usually cost a lot, the process is too complicated to promote. Therefore, the researchers develop laser cladding technology that combines tungsten carbide as a high-performance cladding with the base firmly. It can remarkably improve the heat resistance, oxidation resistance, electrical characteristics and wear and corrosion resistance of the base surface.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Low Temperature Heat Treatment of Tungsten Trioxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 18:26

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder and Tungsten Capacitor Element

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 17:15

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Deallocation Details of A Tungsten Heater Device

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 16:33

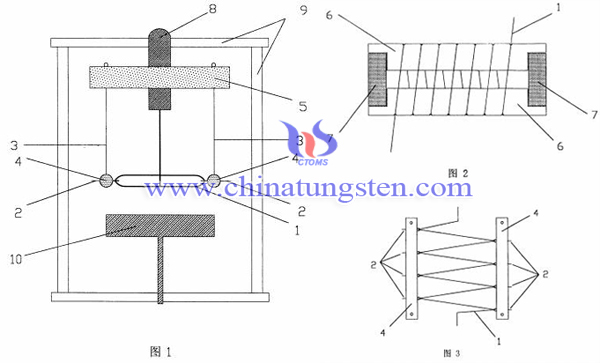

A kind of tungsten heater device would not deform under high temperature, including quartz tube cavity, tungsten heating part and the sample stage, wherein the tungsten heating part is composed of solenoid-shaped flat heating tungsten wire, fastening tungsten wire, suspension tungsten wire, boron nitride ceramic rods and fixing ceramic. And using special tungsten wound support for a wolfram heater that would not deform under high temperature, and tungsten wound support consists of setting frame and distance plate. The shape and spacing of tungsten wire can be made for one time, width is adjustable and it can be very easily removed from the wound support.

Figure 1 is a schematic view of tungsten heater device, figure 2 is a schematic view of setting and winding of tungsten wire, figure 3 is a schematic view of fixation of a tungsten wire. Quartz tube cavity 9 forms a sealed reaction chamber, the sample stage 10 and the tungsten heating part is put on lower portions of quartz tube cavity 9. Tungsten width, spacing, and number of turns are required to be determined in advance in according with the experimental apparatus and the temperature uniformity. After that the edge grooves of setting frame 6 and size of the distance plate 7 is also determined.

The straight tungsten wires are moved round in constant head tank, and bends parts should be adjusted by the fixture tools. After removing the distance plate 7, remove setting frame 6. As shown in figure 3, each tungsten wire ends is moved round by fine tungsten wire, and then it is inserted into the corresponding holes on boron nitride ceramic rods 4 and to be clamped with small pieces of tungsten, fastened to the boron nitride ceramic rod 4. The shape of the tungsten wire would be fixed because machinability and rigidity at high temperature of the boron nitride ceramic rod 4.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Advantages of A Tungsten Heater Device

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 16:31

A kind of tungsten heater has the following significant advantages:

1. When heating tungsten wire at high temperatures, it would not deform or twisted. Even work continuously for dozens of hours or intermittent accumulated for several hundred of hours, it is still able to maintain its original shape, so that the life of tungsten can be maximized extend. It not only saves costs and time, but also ensures that unity of experimental conditions in a series of comparative experiments.

2. The substrate surface temperature covered by the tungsten wire can be maintained substantially uniform state, prompting area of high-temperature tungsten wire of decomposition gas increases, so the gas can be more fully decomposed, the decomposition rate of the gas increase. Quality and growth rate of the film is also improved accordingly. In CVD diamond film growth experiment, the nucleation and growth can be maintained uniform and under the high methane concentration (about 2%) , it still able to maintain a high quality film. This is because the change of tungsten wire winding way, and gas decomposition rate increases, the surface temperature of the substrate becomes uniform, as amorphous atomic hydrogen components are etched more fully.

3. The current of this kind of tungsten wire has increased over the same length of the solenoid-shaped tungsten wire current, but it will not exceed the rated current value of the transformer and the lead, so it is no need to replace for the new high current transformers. What’s more, the wolfram wire is also not affected the reaction chamber size. This kind of wolfram heater device has the characteristic of fast speed of bleeding, charging, heating and cooling, small consumption of power and gas, low-cost, which is good for CVD system for industrial applications.

The device is applicable to the diamond film, preparation and basic growth research of cubic boron nitride film and the amorphous silicon film.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

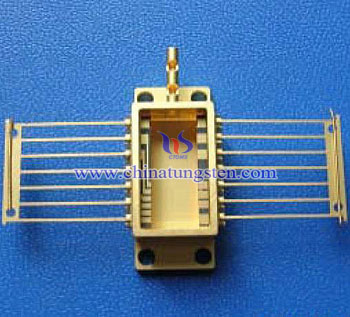

Tungsten Copper Heat Sink — Hot Forging

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 15:18

Tungsten copper heat sink materials not only have high density, high strength, high melting point and excellent wear and corrosion resistance, but also have high heat resistance and perfect thermal and electrical conductivity. It is important that it has matching thermal and linear coefficient of expansion to the chip and ceramic, which has a broad prospect in RF (Radio Frequency), microwave, optical communications and some other high-power electronic components. But the common tungsten copper heat sink materials fabricated by PM after Cu infiltrated will unavoidably appear some pores and defects, which has a bad effect on the hermeticity of electronics packaging materials. Hot forging is a kind new process that organically combines PM and hot hammering, it heated after sintered preform and forged in a closed die cavity. It can not only reduce the cutting loss effectively, but also can promote the densification and improve the structure and properties.

From the point of view microstructure, after forging high temperature tungsten copper composite material no larger diameter of the copper-rich region and Cu phase distributes uniformly. At the same time between the tungsten particles combine more closely, product density has been increased dramatically. In addition, after twice after forging, microstructure changes tungsten-copper composite material is not obvious at this time shows the deformation resistance and forging pressure inside the sample is quite internal sample no longer produce significant deformation and dislocation. After hot forging, tungsten copper material inside the pores decrease, increase density, air tightness and physical performance improved significantly. Through ultrasonic scanning analysis, we can find that the sample without forging has many small pores inside and there is almost no white dot after forging. On the other hand, processing tungsten-copper material through the internal temperature after forging without causing cracks larger pores gradually shrink or even disappear, thereby increasing the density of tungsten copper material, tungsten copper microstructure uniformity is further improved.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact Used for SF6 Circuit Breaker

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 15:16

SF6 circuit breaker uses SF6 gas as dielectric medium. Compared with conventional air circuit breaker, it also belongs to air blast circuit breaker. But there are some differences, such as lower working pressure, in the process of blowing the arc, and gas is not discharged to the atmosphere, but in a closed loop system used. Due to the perfect insulation and interrupter properties of SF6 gas, SF6 circuit breaker has many advantages, such as good breaking ability, high voltage suitable for fracture, allow continuous breaking more frequently, small in noise, no security threat, small electro-mechanical wear and so on which is a king of “maintenance-free” circuit breaker with excellent performance and has been widely used in high-voltage circuit. As the voltage level of the SF6 circuit breakers imposed increasingly higher and higher, the requirements of physical and electrical performance is also increasing.

In general, SF6 circuit breakers should meet the design requirements that the hardness of contact > HRB 82, the density > 13g / cm3, the conductivity ≥ 50% IACS, and after a 20-time All-breaking capacity test, the contact surface burning amount should not exceed 3mm. Conventional ratio has two kinds of W-Cu40 and W-Cu 35, wherein the content of W should not be too high (≤70%), otherwise the burning rate will increase. First of all, choose fine W powder is beneficial for reducing the burning rate, but too fine W powder will make liquid copper difficult infiltrate and easily form crumb defects on the matrix. Adding sintering additives will remarkably decrease the electrical conductivity and the burning loss has an increasing trend on the surface of contacts after cut-off. In addition, the granularity composition also needs a proper mixing ratio; viewed from the manufacturing process, add proper amount of induced Cu powder when mixing; leave some place for re-press when compacting; the volume of liquid copper must be equal to tungsten skeleton pore volume during sintering infiltration and it should be surface cleaned after cooling.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Product Catalogue

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 19:37

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com