Deallocation Details of A Tungsten Heater Device

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 16:33

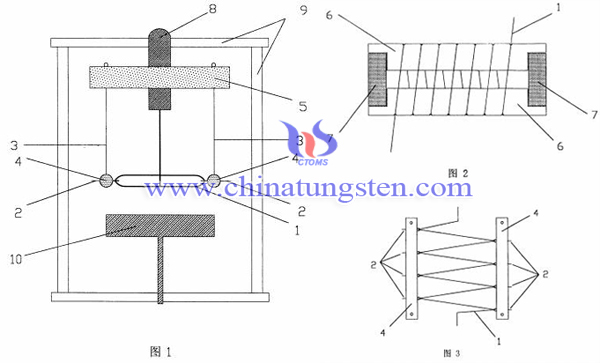

A kind of tungsten heater device would not deform under high temperature, including quartz tube cavity, tungsten heating part and the sample stage, wherein the tungsten heating part is composed of solenoid-shaped flat heating tungsten wire, fastening tungsten wire, suspension tungsten wire, boron nitride ceramic rods and fixing ceramic. And using special tungsten wound support for a wolfram heater that would not deform under high temperature, and tungsten wound support consists of setting frame and distance plate. The shape and spacing of tungsten wire can be made for one time, width is adjustable and it can be very easily removed from the wound support.

Figure 1 is a schematic view of tungsten heater device, figure 2 is a schematic view of setting and winding of tungsten wire, figure 3 is a schematic view of fixation of a tungsten wire. Quartz tube cavity 9 forms a sealed reaction chamber, the sample stage 10 and the tungsten heating part is put on lower portions of quartz tube cavity 9. Tungsten width, spacing, and number of turns are required to be determined in advance in according with the experimental apparatus and the temperature uniformity. After that the edge grooves of setting frame 6 and size of the distance plate 7 is also determined.

The straight tungsten wires are moved round in constant head tank, and bends parts should be adjusted by the fixture tools. After removing the distance plate 7, remove setting frame 6. As shown in figure 3, each tungsten wire ends is moved round by fine tungsten wire, and then it is inserted into the corresponding holes on boron nitride ceramic rods 4 and to be clamped with small pieces of tungsten, fastened to the boron nitride ceramic rod 4. The shape of the tungsten wire would be fixed because machinability and rigidity at high temperature of the boron nitride ceramic rod 4.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com