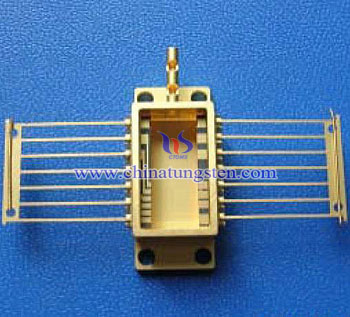

Tungsten Copper Heat Sink — Hot Forging

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 15:18

Tungsten copper heat sink materials not only have high density, high strength, high melting point and excellent wear and corrosion resistance, but also have high heat resistance and perfect thermal and electrical conductivity. It is important that it has matching thermal and linear coefficient of expansion to the chip and ceramic, which has a broad prospect in RF (Radio Frequency), microwave, optical communications and some other high-power electronic components. But the common tungsten copper heat sink materials fabricated by PM after Cu infiltrated will unavoidably appear some pores and defects, which has a bad effect on the hermeticity of electronics packaging materials. Hot forging is a kind new process that organically combines PM and hot hammering, it heated after sintered preform and forged in a closed die cavity. It can not only reduce the cutting loss effectively, but also can promote the densification and improve the structure and properties.

From the point of view microstructure, after forging high temperature tungsten copper composite material no larger diameter of the copper-rich region and Cu phase distributes uniformly. At the same time between the tungsten particles combine more closely, product density has been increased dramatically. In addition, after twice after forging, microstructure changes tungsten-copper composite material is not obvious at this time shows the deformation resistance and forging pressure inside the sample is quite internal sample no longer produce significant deformation and dislocation. After hot forging, tungsten copper material inside the pores decrease, increase density, air tightness and physical performance improved significantly. Through ultrasonic scanning analysis, we can find that the sample without forging has many small pores inside and there is almost no white dot after forging. On the other hand, processing tungsten-copper material through the internal temperature after forging without causing cracks larger pores gradually shrink or even disappear, thereby increasing the density of tungsten copper material, tungsten copper microstructure uniformity is further improved.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com