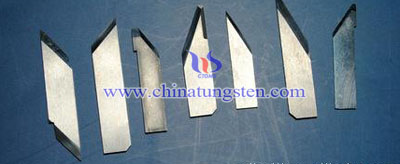

Tungsten Carbide Fiber Cutter

- Details

- Category: Tungsten Information

- Published on Friday, 08 July 2016 15:32

In the textile and chemical fiber industry, in order to blend chemical fiber cotton and other natural fibers, the continuous fiber tow after dragging, crimping and heat setting treatment needs to be cut into predetermined length by fiber cutters. In the cutting process, with the increasing using time, the properties of cutter will gradually reduce until passivated, which has an effect on the quality and efficiency of fiber cutting directly. Tungsten carbide fiber cutter has many advantages, such as high hardness, high strength, high impact toughness and excellent wear and corrosion resistance, which are beneficial for the practical applications of textile and fiber industry. Fiber cutting depends on the contacting movements between the cutter and the tow, which essentially cutter pushes the fiber to produce deformation and fracture.

In general, the materials used for fiber cutter include tool steel, high-speed steel, tungsten carbide and so on. Tool steel requires several sharpening during the process, frequent tool change will result in cutting quality fiber product instability, labor-intensive, low productivity, now gradually being eliminated; there are some highly dispersed and stable VC hard particles in the high-speed steel organization. Dispersion strengthening improves the hardness of the matrix and the stable VC hard particles greatly improve the wear resistance of the materials. In addition, adding some Si and Al elements in high-speed steel can effectively improve the hardness and wear resistance, and adding Nb element will be reacted with C to generate diffused fine NbC, which can effectively prevent the grain growth; super hard high-speed steel and tungsten carbide materials are composed of W, Mo, Co and other rare metals, which have excellent cutting performance and longer service life. But they usually cost a lot, the process is too complicated to promote. Therefore, the researchers develop laser cladding technology that combines tungsten carbide as a high-performance cladding with the base firmly. It can remarkably improve the heat resistance, oxidation resistance, electrical characteristics and wear and corrosion resistance of the base surface.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com