Multiple Composite Rare Earth Tungsten Electrode Cost Advantage

- Details

- Category: Tungsten Information

- Published on Thursday, 14 July 2016 17:54

Multiple composite rare earth electrode can not only adapt to different welding current range and different welding materials, but also it has good weldability. Composite tungsten electrode rare earth doped quantity is similar to tungsten electrode doped with single rare earth oxide. Rare earths and thorium has large price differences, but the quantity is small, so raw material cost different between composite electrode and thorium tungsten electrode is small. In addition, during the composite electrode manufacturing, the manufacturers introduced new technology, thus greatly improving the finished product ratio of electrode. And during the preparation, the factory also uses new equipment, which can simplify processes and equipments, improve work efficiency, reduce labor intensity, so that the energy, equipment and labor costs are significantly reduced during production. Meanwhile, manufacturers directly uses APT as raw material, mixed rare earth nitrate, eliminating the APT firing process, greatly reducing the cost of production. The initial temperature of subsequent processing is higher, but its energy consumption is relatively small than APT calcining consumed. Taking all these factors, the production cost of composite electrode is slightly lower than tungsten electrode doped with single rare earth oxide, such as cerium tungsten electrode, thorium tungsten electrode.

Thorium tungsten electrode has excellent welding performance, although thorium tungsten electrode tungsten may be substituted with cerium and lanthanum tungsten electrode, but only a small part, thorium tungsten electrode consumption is still the greatest. In terms of performance composite electrode is greater than thorium tungsten electrode. Further, thoriated tungsten electrode has radioactive contamination, so during production and transportation process should increase the radiation protection fee and composite electrode has obvious cost advantages than it. Composite rare earth tungsten electrode only has the price advantage but excellent performance, so if it having same price with cerium tungsten electrode and thorium tungsten electrode may has bright market prospect. On the other hand, if its price is small higher than cerium tungsten electrode and thorium tungsten electrode, considering its welding performance, than it will accepted.

Multiple composite rare earth electrode no radioactive contamination, is a green electrode.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

YG8 Tungsten Carbide Drill Bits

- Details

- Category: Tungsten Information

- Published on Thursday, 14 July 2016 15:02

YG8 tungsten carbide drill bit is a kind of rock drilling tool that has been widely used in mine drilling, building construction and transport facilities. It is composed of tungsten carbide with high hardness and excellent wear resistance and steel welded. In the process, tungsten carbide drill bits have to endure complex impacting and twisting forces. According to the shapes of the drill bits, YG8 tungsten carbide drill bits can be specifically divided into linear, crossed, X-shaped and button. Linear carbide drill bit is suitable for light internal combustion electric, pneumatic and hydraulic soft rock drilling and convenient for grinding; the crossed and X-shaped drill bit is suitable for greater impact power drills, drilling fractured rock formations and strong abrasive rock formations, such as limestone, granite and marble; button bits usually used with tungsten carbide buttons, in power drills with a large impact, compared with sheet insert drill bits has better performance in applicability, drilling efficiency, service life and the hole quality. In addition, button drill bits can be also divided into coal button, flat button and bullet button according the button profiles.

The main failure mode of tungsten carbide sheet includes breaking and shedding, which welding quality directly affects the service life of drilling tool. The drill bit brazing uses high-frequency induction, the advantage is rapid heating process, the solder liquefaction process short, can effectively reduce the burning of carbide and oxide process, which is beneficial for improving the quality of welding. And add proper amount of Mn element in brazing materials, it can be based on not reduce the plasticity and remarkably improve the strength, elasticity, wettability and corrosion resistance of drill bits. In addition, some of the parameters in brazing process, such as brazing seam gap, heating rate, cooling rate, the induction coil design, solder flux, method of adding and weldments surface roughness should be controlled in a reasonable range, or they will has an bad effect on the quality of welding and increases the residual stress inside of tungsten carbide drill bits.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Reason of the Tungsten Heater Loss in the Aluminizing Process ——Oxidation

- Details

- Category: Tungsten Information

- Published on Thursday, 14 July 2016 11:06

Another reason for the large consumption of tungsten heater is oxidation. Tungsten heater oxide is that the wolfram wire would react with oxygen in the air, which could lead to breakage of heating element, thus shortening its life time. Aluminizing for too long can also lead to tungsten wire directly bake surface aluminum layer and the wire become yellow.

Another reason for the large consumption of tungsten heater is oxidation. Tungsten heater oxide is that the wolfram wire would react with oxygen in the air, which could lead to breakage of heating element, thus shortening its life time. Aluminizing for too long can also lead to tungsten wire directly bake surface aluminum layer and the wire become yellow.

In general, the oxidation temperature of heating element is about 850℃, if the cooling is not sufficient after evaporating, the part of wolfram heater that exposed to the air would react with oxygen, causing oxidation. During the process of mass production, the aluminum evaporation is carried out continuously. Before steaming aluminum screen, air should be added into the vacuum vessel, or steaming aluminum screen cannot be moved away. If the heater element cannot be adequately cooled, the amount of oxygen in the air can easily oxidize the heating element. After oxidizing, the effect of heating element would be reduced, thus affecting the efficiency of the coating.

For the oxidation problem, operators can let the heating element to be maximized cooled before opening the leakage valve, which can reduce the chance for high temperature oxidation of wolfram heater. On the other hand, it is required that operators should maintain and inspect equipment of aluminizing regularly, to keep cleanliness. The improvement of the degree of vacuum in deposition process can effectively avoid the heating element to be oxidized at high temperatures, thereby extending the life time of the heater element. In addition, clean fixtures of wolfram heater regularly, do not use dirty fixtures, which would affect the degree of vacuum. The groove of fixtures of wolfram heater should be maintained smooth, to avoid the residual foreign body to damage heating element. Through these measures, it can reduce frequency for operators to switch the heating element, further improve produce efficiency, reduce consumption of materials.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Reason of the Tungsten Heater Loss in the Aluminizing Process ——Aging

- Details

- Category: Tungsten Information

- Published on Thursday, 14 July 2016 11:04

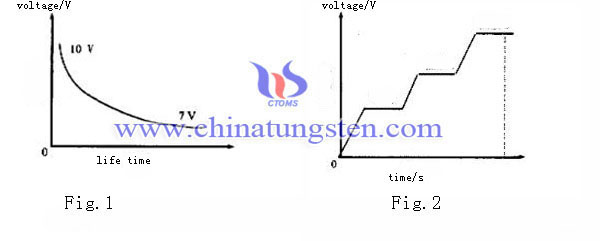

Aging is one of the important factors in the consumption of tungsten heater. Under normal circumstances, the life time of the tungsten heater is more than 300 times, but if done incorrectly, heater element would change color into yellow, and then in the central of tungsten heater would have irregular cracks which cannot process the normal evaporation process of aluminum, that is the aging of wolfram heater. When the evaporation of aluminum, under the saturated vapor pressure (1.33Pa), evaporation temperature of aluminum is 1490K. If the voltage is too high during the evaporation process, the high input power would cause the temperature of heating element is too high, thus greatly reducing the life time of wolfram heater. Figure 1 is a graph showing the heater element voltage and lifetime relationships. From the figure it is clear that with the increase of the number of evaporation, the voltage would decline rather than rise. This is because that the use of time would accelerate the aging of materials, thereby reducing the heating element resistance. If you use the same or a higher voltage, which would undoubtedly increase the input power of wolfram heater, causing the rise of the temperature of wolfram heater, leading to significantly shorten its service life. However, due to the use of heating element time is inconsistent, the voltage cannot be unified adjusted unless replace all the tungsten wire, but this would affect production and increase costs. What’s more, the life time of the tungsten wire is not the same, so it is unrealistic to replace them unified.

For this problem, the operator can reduce time of evapotranspiration, generally holding for 20 ~ 30s, and minimize the compression time for wolfram heater in the premise of complete evapotranspiration. By reducing evapotranspiration time to reduce the time of overheating, thereby avoiding heater element temperature is too high, too fast aging. Figure 2 is a graph showing the heater element voltage and time relationships.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano Tungsten Trioxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2016 18:44

Tungsten trioxide is a η-type wide band gap semiconductor oxide (with the band gap of about 2.4~2.8eV), at low and room temperature, WO3 exist in the form of monoclinic and triclinic phase; whereas at high temperatures, the orthogonal and tetragonal phases will come into being. The ideal crystal structure of WO3 can be seen as consisting of six O atoms around the central atom W and form the octahedral of tungsten – oxygen [WO6], they are connected together via common vertices; there are many gaps between the octahedral to form the various channels, and these distribution channels serve as distribution channels and embedding position which are good body injection plasma of H+, Li + and other ions. Therefore, tungsten trioxide as the most classic electrochromic inorganic material, with its fast response, high coloring efficiency, high coloring and achromatic contrast and other properties, is widely used in electrochromic devices, photochromic devices and intelligent display and other fields.

Tungsten trioxide is a η-type wide band gap semiconductor oxide (with the band gap of about 2.4~2.8eV), at low and room temperature, WO3 exist in the form of monoclinic and triclinic phase; whereas at high temperatures, the orthogonal and tetragonal phases will come into being. The ideal crystal structure of WO3 can be seen as consisting of six O atoms around the central atom W and form the octahedral of tungsten – oxygen [WO6], they are connected together via common vertices; there are many gaps between the octahedral to form the various channels, and these distribution channels serve as distribution channels and embedding position which are good body injection plasma of H+, Li + and other ions. Therefore, tungsten trioxide as the most classic electrochromic inorganic material, with its fast response, high coloring efficiency, high coloring and achromatic contrast and other properties, is widely used in electrochromic devices, photochromic devices and intelligent display and other fields.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

New Boiler Energy Saving Regulation, WO3 Denitration Catalyst Helps Meet Emission Standard

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2016 18:41

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

China WO3 Denitration Catalyst Market Rising

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2016 18:38

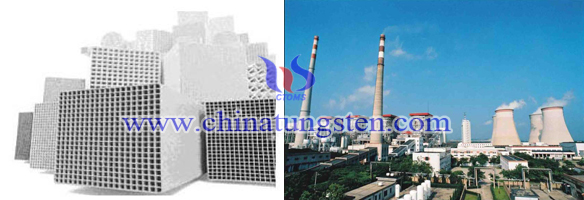

Early in the 1970s, the Japanese Nippon Shokubai Kasei Co., Ltd began to develop a honeycomb denitration catalyst, and realized the industrial production in the late 1980s, and then they transferred the technology to foreign countries. With the exacerbating of air pollution, NOx removal and purification have started to get attention, many countries, especially the United States, Japan and other developed countries, began to develop the denitration catalysts and get them applied. At present, China has more than 20 manufacturers of the denitration catalyst market, and about 80% of the domestic market is occupied by the United States, Japan and other foreign technologies, using the self-developed technology to produce the catalyst has only share 20% of the market.

Early in the 1970s, the Japanese Nippon Shokubai Kasei Co., Ltd began to develop a honeycomb denitration catalyst, and realized the industrial production in the late 1980s, and then they transferred the technology to foreign countries. With the exacerbating of air pollution, NOx removal and purification have started to get attention, many countries, especially the United States, Japan and other developed countries, began to develop the denitration catalysts and get them applied. At present, China has more than 20 manufacturers of the denitration catalyst market, and about 80% of the domestic market is occupied by the United States, Japan and other foreign technologies, using the self-developed technology to produce the catalyst has only share 20% of the market.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Comparison of Composite Rare Earth Tungsten Electrode and Thorium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2016 18:27

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Carbon Doped Tungsten Oxide Nanorods NO2 Sensor Prepared by Glancing Angle RF Sputtering

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2016 16:20

Nanostructures such as nanowires, nanorods, nanotubes of metal oxide semiconductor (MOS) materials have recently attracted monumental interest in gas-sensing applications because of their excellent performances owing to their large surface to vol-ume ratio, lower electron recombination rate and high stability. Among various MOS materials, tungsten trioxide (WO3) is a highly promising candidate due to its fast response with high sensitivity toward NOx.

Nanostructures such as nanowires, nanorods, nanotubes of metal oxide semiconductor (MOS) materials have recently attracted monumental interest in gas-sensing applications because of their excellent performances owing to their large surface to vol-ume ratio, lower electron recombination rate and high stability. Among various MOS materials, tungsten trioxide (WO3) is a highly promising candidate due to its fast response with high sensitivity toward NOx.

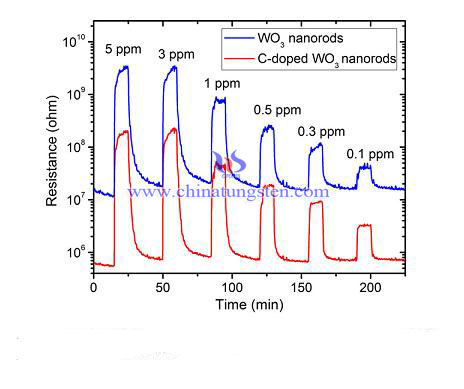

Glancing angle depositio (GLAD) technique is a relatively new method for fabrication of well-ordered and sophisticated nanostructures i.e. nanorods, nanoblade and zigzag nanocolumns. It is a modified physical vapor deposition process, in which substrate surface is rotated and tilted to an angle greater than 80° with respect to the normal of substrate surface or less than 10°with respect to the direction of vapor flux. The vapor molecules directed to the substrate will experience shadowing and limited surface diffusion condition leading to the formation of isolated nanostructures. With this technique, the shape, size and density of nanostructures can be well controlled by deposition parameters such as deposition angle, operating pressure, substrate temperature, deposition power, and so on. In this report, carbon-doped WO3 nanorods is fabricated by GLAD technique using RF magnetron sputtering and investigated for NO2 gas sensing application. In addition, its performances are comparatively studied with that of the undoped ones.

Carbon-doped and undoped WO3 nanorods gas sensors have successfully been fabricated by the GLAD technique with RF magnetron sputtering. By this technique, the vertically well-aligned homogeneous WO3 nanorods with very low defect were achieved over a large area. It was found that carbon doping does not change any crystalline structure but increases the grain size and accelerates the nanorods growth leading to relatively high aspect ratios as compared to the undope one. The fabricated carbon-doped WO3 nanorods sensor exhibits high response and selectivity to NO2 at the concentration range of 0.5–5 ppm at an optimum operating temperature of 250℃. In addition, the carbon-doped sensor still works well for NO2 detection at lower operating temperature of 150℃ due to the decrease of activation energy and alteration of the depletion layer. Therefore, carbon-doped well-ordered WO3 nanorods with improved NO2 gas-sensing performances in terms of response, response time, selectivity and operating temperature has been realized. Moreover, this technique offers distinct advantages over other methods such as high productivity, simplicity and low cost for well-ordered nanostructure construction.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nanocrystalline Tungsten Oxide Thick Film Sensor for the Detection of H2S Gas

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2016 16:10

Metal oxide semiconductors (MOS) have been utilized as gas sensing active materials for half a century. One of the most promising solid-state MOS chemo sensors is n-type semiconducting tungsten oxide-based gas sensor. They have demonstrated novel sensing properties such as high sensitivity, fast response time and low operation temperature. In particular, pure or doped tungsten oxide is a promising material for the detection of various substances, e.g., H2,H2S,NOx, NH3 and ethanol.

Metal oxide semiconductors (MOS) have been utilized as gas sensing active materials for half a century. One of the most promising solid-state MOS chemo sensors is n-type semiconducting tungsten oxide-based gas sensor. They have demonstrated novel sensing properties such as high sensitivity, fast response time and low operation temperature. In particular, pure or doped tungsten oxide is a promising material for the detection of various substances, e.g., H2,H2S,NOx, NH3 and ethanol.

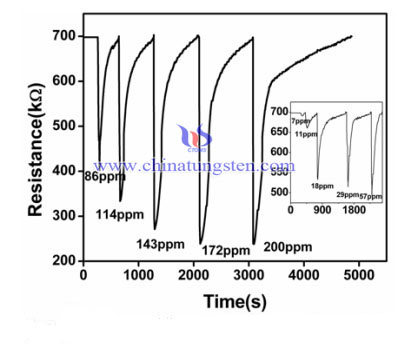

Scientists have investigated the sensing characteristics of WO3 nanoparticles to H2S in the 7 to 200 ppm range at working temperatures of the range of 100–225 ℃. Semiconductor gas sensors based on nanocrystalline WO3 powders were prepared by acid precipitation method. The thick films of the powder were coated on to glass substrate, annealed at 600 ℃ and its response to different concentration of H2S gas was studied. Sensor behavior is presented in detail for representative concentration of 18ppm. The result showed that WO3 nanoparticles are good candidates for sensing H2S at a temperature of 200 ℃.

Sensitive layers of tungsten oxide were prepared by dispersing the prepared tungsten oxide powder in methanol and drop casting on glass substrates followed by overnight annealing at 600 ℃. The obtained crystalline phase of WO3 nanoparticles was triclinic in nature. The structure of sensor was characterized using XRD. The surface morphology and elemental composition were characterized by scanning electron microscopy and energy dispersive X-ray analysis. It was found that the WO3 samples consisted of crystalline aggregates. This was confirmed in TEM results. The particles were spherical in nature. Gas sensing properties of samples were studied for the detection of H2S gas. Resistance of the films decrease upon exposure to gases and attained a saturation value.

Sensor regains its original value after test gas is removed. Sensor exhibit good sensing characteristics to H2S in the concentration range studied, 7 to 200 ppm over the temperature range 100-125 0C. The best results were obtained at operating temperature of 200 ℃ with a sensitivity of 1.3. Response and recovery time of sensor at this optimum temperature was 22 seconds and 4.1 minutes respectively. Lowest measurable concentration is found to be 7ppm. Resistance always returned to its initial value after the test gas is shut off for all concentration studied. Results indicate that response of sensor is reproducible during this test.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com