Zirconium Tungsten Electrode Rod Processing

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 17:58

Obtained tungsten zirconium alloy bar by powder metallurgy, the electrode rod after swaging, drawing and a series of processing can obtain zirconium tungsten electrode. To carry hardness test on zirconium tungsten electrode found that the hardness value of work surface is similar to negative working surfaces hardness value, but the top edge hardness values is significantly higher than the bottom edge hardness values, and therefore the electrode rod in the swaging is easily to form transverse cracks on bottom edge, and even breakage.

ZrO2 is a reversible phase transition. During sintering process, the temperature changes will cause ZrO2 phase transformation from monoclinic to tetragonal transformation and the volume change is substantially as follows:

△ V12 = (0.14045-0.13420) /0.14045≈4%

△ V13 = (0.14045-0.13178) /0.14045≈6%

When the monoclinic changes to tetragonal transformation, ZrO2 volume declines by 4%. When the temperature is low, the tetragonal will change to monoclinic and the volume expansion rate of ZrO2 is about 4%. When the forging temperature at 2300 ℃, its volume shrinkage rate is about 6% and 6% volume expansion during cooling. Thus, around the ZrO2 particle is easy to form small cracks or voids and these voids and cracks are one of the main reason that zirconium tungsten alloy bar brakeage during process. ZrO2 chemical properties is stable and at high temperatures and hydrogen atmosphere it will not be reduced to zirconium, but at 1600 ℃, ZrO2 will react with carbon to from ZrC in the grain boundaries. ZrC is more brittle and hard than ZrO2, so it easy becomes brittle fracture sources. In addition, the negative work surface of electrode has low density on the edge, if cogging temperature is low, then the low-density edge of negative work surface is prone to form transverse cracking.

ZrO2 phase change and uneven density are likely to cause cracks or fracture on electrode rod, affecting its processing performance, which has a certain impact on electrode subsequent use.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Zirconium Tungsten Electrode Manufacturing

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 17:56

The most important feature of zirconium tungsten electrode is under high load current the tip can still maintain spherical, reducing the tungstenizing phenomenon. And it is commonly used for aluminum and its alloys welding, magnesium and its alloys welding and coated oxide film copper welding. Doped with small amount of zirconia (ZrO2) on the basis of tungsten substrate and produced by powder metallurgy after processing can obtain zirconium tungsten electrode. ZrO2 uniformly dispersed in the grain boundaries and grains can hinder grain growth, grain boundary slipping and dislocation climbing, which play a good strengthening effect on electrode, therefore zirconium tungsten electrode has good high temperature performance, stable arcing, low arc voltage, ablation resistance and non-radioactive and other good properties. Compared to lanthanum tungsten electrode, thorium tungsten electrode and other tungsten electrode material it has stronger advantages. Comparing zirconium tungsten electrode (WZ8) with lanthanum tungsten electrode (WL10) found, WZ8 used for AC welding the electrical property is similar with WL10, but the burning rate is less than WL10.

Manufacturing processes:

1. The zirconium oxychloride (ZrOCl2 • 8H2O) was dissolved in deionized water and added WO3 with constant stirring.

2. The mixed solution after dehydrated, dried and 2 times reduction can obtain WZ8 powder. The Fsss particle size is about 2.5 ~ 3.5um.

3. Using 500T hydraulic machine pressed WZ8 powder into 13mmx13mmx520mm square strip and the weight is about 940g.

4. Then after pre-sintered and incipient fusion to obtain zirconium tungsten alloy billet and the density is about 17.0 ~ 18.0g / cm3.

5. After swaging, stretching and other subsequent processing can obtain a diameter of 1.0mm zirconium tungsten electrode.

During the production, ZrO2 phase transformation will lead to shrinkage and expansion, so around the ZrO2 particle is easily to form voids or cracks, affecting the processing performance of the electrode. Further, the electrode density is not uniform, if the cogging temperature is low, then it will produce cracks on electrode, causing subsequent processing difficulties.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

New WO3 Denitration Catalyst Anti-Alkali Metal and SO2 Poisoning

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 17:51

Earlier this year, Tang Xingfu, the professor of environment catalytic group, Environmental Science and Engineering of Fudan University, developed a new denitration catalyst technology of simultaneous anti-alkali metal and SO2 poisoning. Research data in China and foreign shows that compared with the primary source, a secondary-generation components account for more than half the proportion of PM2.5 and has a higher percentage at the time of the occurrence of haze. This technology can effectively control NOx which is the PM2.5 precursors emission, and have an important positive role in the reducing of particulate pollutants in the atmosphere to secondary formation of NOx conversion.

Earlier this year, Tang Xingfu, the professor of environment catalytic group, Environmental Science and Engineering of Fudan University, developed a new denitration catalyst technology of simultaneous anti-alkali metal and SO2 poisoning. Research data in China and foreign shows that compared with the primary source, a secondary-generation components account for more than half the proportion of PM2.5 and has a higher percentage at the time of the occurrence of haze. This technology can effectively control NOx which is the PM2.5 precursors emission, and have an important positive role in the reducing of particulate pollutants in the atmosphere to secondary formation of NOx conversion.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3-Based Sulfur Dioxide Gas Sensor

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 17:44

With the increasing attention of environmental protection, air quality is also get more and more attention; for the purposes of environmental protection, improve air quality, the development of gas sensor with high sensitivity, low cost, easy to maintain is also increasingly urgent, thus to effectively test and inspect a variety of gases of toxic, hazardous, flammable, explosive and so on. Chemical gas sensor of metal oxide semiconductor sensor has been extensively studied, due to its high sensitivity, fast response, and low cost etc..

With the increasing attention of environmental protection, air quality is also get more and more attention; for the purposes of environmental protection, improve air quality, the development of gas sensor with high sensitivity, low cost, easy to maintain is also increasingly urgent, thus to effectively test and inspect a variety of gases of toxic, hazardous, flammable, explosive and so on. Chemical gas sensor of metal oxide semiconductor sensor has been extensively studied, due to its high sensitivity, fast response, and low cost etc..| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Three Development Trends

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 14:50

Due to the higher hardness, strength and excellent wear and corrosion resistance, tungsten carbide button has been widely used in rock drilling, oil-field drilling and tunnel drilling. However, with the conditions has become more complex, tungsten carbide button own properties were difficult to meet the requirements now. So the relevant researchers have studies deeply, such as gradient structure, non-uniform structure and add trace elements.

1. Gradient structure: Gradient tungsten carbide is also called multi-phase and multi-structure alloy, which has high toughness and high wear resistance. Its principle is that uses low-carbon alloy and obtainedη-phase alloy by vacuum sintering, treated in a carburizing atmosphere thereby changing the distribution of the binder phase, so that different parts of the distribution of different alloy binder phase content improved. The experiment shows that compared with common tungsten carbide drills, tungsten carbide button bits with gradient structure has longer service (40%-60%) and the wear resistance improved 40%-90%.

2. Non-uniform structure: Non-uniform structure carbide can be main divided into two types, one is mixture with fine grains and coarse grains of WC, the other is high-Cobalt and low-cobalt alloy were separately granulated and then mixed with each other inhomogeneous structure of the alloy obtained. This kind of carbide button has good toughness and excellent wear resistance, but it still in the research and development stage.

3. Add trance elements: According to different conditions, such as some special requirements for the hardness, the wear and corrosion resistance, we can add some trace elements correspondly. There are two adding methods: one is added directly in solid form, take TaC and TiC as example, add Ta, Ti, W, C directly; the other is add TaC and TiC in elemental form. Adding small amount of TiC and TaC is beneficial for improving the binder phase composition and microstructure of the grain boundary, so as to effectively improve the wear resistance, impact toughness and resistance thermoplastic change capability. The effect of two ways is basically the same.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Powder Special Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 14:46

Tungsten carbide powder special manufacturing processes include ultra-fine and nano WC powder, Co powder, WC-Co composite powder, additives and so on. Ultra-fine and nano WC powder manufacturing process can be specifically divided into WO3 direct carbonization, rapid carbothermal reduction, purple tungsten precursor preparation, plasma chemical synthesis, etc. The basic process of WO3 direct carbonization to prepare ultra-fine WC powder: it mixed WO3 powder and carbon uniformly and formed pellets in the rotary kiln two successive reduction - carbonization, resulting in ultra-fine grain WC powder; the advantages of fast carbothermal process includes rapid heating and rapid cooling, can be large-scale, high efficiency, low cost; Purple tungsten precursor preparation method to WO2.72 mainly composed of tungsten oxide having a fine needle structure, hydrogen reduction speed in favor of preparing a uniform ultrafine particles of tungsten powder and tungsten carbide powder; Plasma chemical synthesis powder prepared by high temperature plasma, the particle size of WC powder preparation is 10-50nm in and between the free carbon content can be controlled within the range of 0.1%, the oxygen content can be controlled between 0.3% -0.5%.

The new structure and ultrafine Co powder is a good improvement for this Co binder phase of metal. Co is an allotrope at low temperature hexagonal structure, brittle, easily broken during milling, the high temperature was a face-centered cubic structure, and has good toughness. The hexagonal structures were broken down and sieved to achieve a new structure Co powder. In order to prevent oxidation of Co powder released, paraffin can be used in steam Co powder particle surfaces coated with an organic thin film. In addition, in order to strengthen the binder phase and prevent uneven elution of WC abnormal grain growth, people study a new bond with different phase composition and structure, such as cobalt eutectic alloy, super-alloy bond phase powder. Advantages of the two alloys that WC grains can maintain the initial state until completion of sintering, but also by adjusting the components of the binder phase of cemented carbide to improve the red hardness and creep resistance.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——Technical Requirements

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 11:55

Because that tungsten heater has a high melting point and high corrosion resistance, it is widely used in vacuum metallizing, aluminizing and other decorative items, chromeplate and other mirrors, plastic products. At present, with the rapid development of technology, vacuum coating technology become more and more popular in the world. Thus, manufacturers and buyers and sellers should have knowledge about heated tungsten national standard, in order to improve production quality and level of sales of the products.

Trademarks of wolfram heater include WJ0Z, WJ1Z, WJ2Z, WJ3Z, and their materials are WJ0, WJ1, WJ2, and WJ3. The first three grades of wolfram heater are mainly used as heating elements for electric vacuum steam for aluminizing, plastic and aluminum mirror evaporated coating and others. WJ3 grade wolfram heater is mainly used as heating element for mirror aluminizing, plastic coating and others.

The technical requirements for wolfram heater should meet the following requirements:

1. The chemical composition of the tungsten heater should be consistent with the article 2.1provision of GB4181 "tungsten wire".

2. Life time of wolfram heater: the life time of a wolfram heater for aluminizing in an electric vacuum device cannot be less than 8 times, the life time of a wolfram heater for other areas cannot be less than 10 times

3. The surface of the tungsten products should be a silver-gray and bright, without any obvious glitches, cracks and oxidation phenomena.

Test method has the following requirements:

1. In accordance with the technical requirements of tungsten products in the first, chemical composition should be in accordance with the article 2.1 in GB4181 "tungsten wire" for analysis.

2. In accordance with article IV of the technical requirements, firstly, the surface quality can be inspected visually, and if there is something not sure, operators can use a magnifying glass to test.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——Dimensional Requirements

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 11:52

Because different applications, tungsten heater can be stranded into single or multi wires according to the samples or the specific requirements of drawings of customers. Pure wire and doped wire are both available. But not all styles wolfram heater can eventually qualified to be used. The National Standard GB SJT 11063-1996 in China makes clear rules about the dimension of the tungsten heater.

At first, the technical requirements of two legs of tungsten heater should be flush with each other, they also need to maintain parallel. Secondly, operators can test the products with eyes, a ruler or vernier caliper.

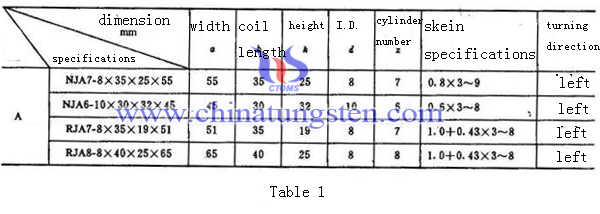

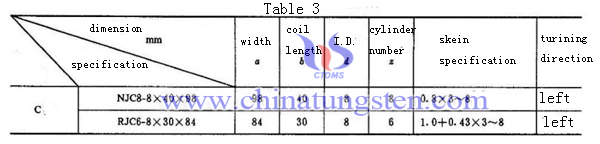

For tungsten heater type A, the National Standard GB SJT 11063-1996 have made the following provisions about its total width, length of the coil, the total height, diameter, the number of circle, specifications and direction of rotation, which is shown in Table 1.

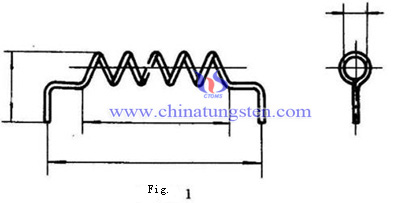

It can be seen from Figure 1 that legs of type A tungsten heater have orthogonal bent, and the direction is downward. What’s more, distance of two legs is long.

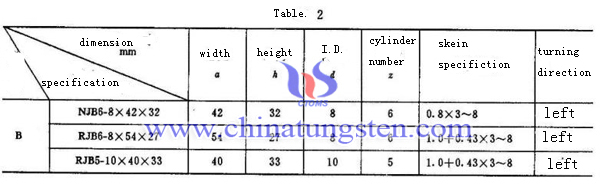

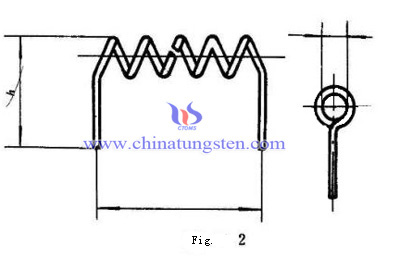

Dimensional requirements of type B can be seen in Table 2. As it can be seen from Figure 2, the distance between two legs of type B is shorter than type A.

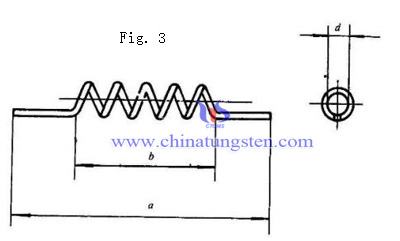

From Table 3, people can clearly know that dimensions and specifications of type C wolfram heater, which only have two specifications. It is made of single tungsten wire, its two legs extending from side to side, the total width is much wider than the type A and B. C type appearance can be seen from Figure 3.

These three types are more common shapes and sizes, in fact, in order to facilitate the subsequent use of the wolfram heater, it is often made into a variety of shapes and sizes. So tungsten heater can be made in accordance with the special requirements of customers.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Research Progress of WO3-Based Semiconductor NO2 Gas Sensor

- Details

- Category: Tungsten Information

- Published on Monday, 25 July 2016 17:31

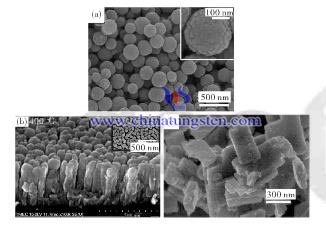

Nitrogen dioxide (NO2) mainly comes from automobile exhaust and industrial emissions, high concentrations of NO2 can cause many environmental problems, such as an optical smog and acid rain; it is one of the major pollutants affecting air quality. At the same time, a higher concentration of NO2 can cause harm to humans, studies showed that when the concentration is over 200ug/m3, nitrogen dioxide would seriously endanger the human respiratory system. Tungsten trioxide as a semiconductor functional material developed in recent years, it has to show a good gas sensing performance to NO2.

Nitrogen dioxide (NO2) mainly comes from automobile exhaust and industrial emissions, high concentrations of NO2 can cause many environmental problems, such as an optical smog and acid rain; it is one of the major pollutants affecting air quality. At the same time, a higher concentration of NO2 can cause harm to humans, studies showed that when the concentration is over 200ug/m3, nitrogen dioxide would seriously endanger the human respiratory system. Tungsten trioxide as a semiconductor functional material developed in recent years, it has to show a good gas sensing performance to NO2.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

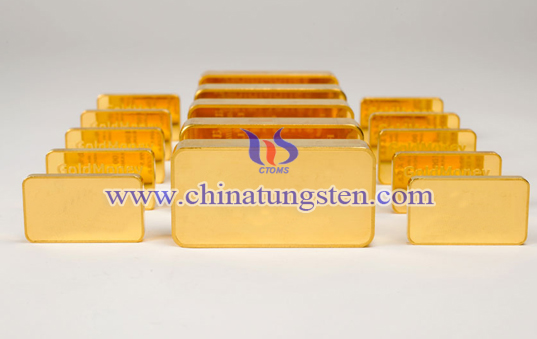

Tungsten Gold Bar for Scientific Research Achievement Commendation

- Details

- Category: Tungsten Information

- Published on Monday, 25 July 2016 15:42

| Tungsten Gold Plated Supplier: Chinatungsten Online t.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com