Research Progress of WO3-Based Semiconductor NO2 Gas Sensor

- Details

- Category: Tungsten Information

- Published on Monday, 25 July 2016 17:31

Nitrogen dioxide (NO2) mainly comes from automobile exhaust and industrial emissions, high concentrations of NO2 can cause many environmental problems, such as an optical smog and acid rain; it is one of the major pollutants affecting air quality. At the same time, a higher concentration of NO2 can cause harm to humans, studies showed that when the concentration is over 200ug/m3, nitrogen dioxide would seriously endanger the human respiratory system. Tungsten trioxide as a semiconductor functional material developed in recent years, it has to show a good gas sensing performance to NO2.

Nitrogen dioxide (NO2) mainly comes from automobile exhaust and industrial emissions, high concentrations of NO2 can cause many environmental problems, such as an optical smog and acid rain; it is one of the major pollutants affecting air quality. At the same time, a higher concentration of NO2 can cause harm to humans, studies showed that when the concentration is over 200ug/m3, nitrogen dioxide would seriously endanger the human respiratory system. Tungsten trioxide as a semiconductor functional material developed in recent years, it has to show a good gas sensing performance to NO2.

In 1991, Aliyama with the team first discovered and reported tungsten trioxide gas sensing properties of nitrogen dioxide, that is tungsten trioxide is a good sensitive material to detect nitrogen dioxide in 300°C. The reaction mechanism of nitrogen dioxide in the surface of the tungsten trioxide is: when the tungsten trioxide nitrogen dioxide reaches the surface, due to electrophilic capacity of NO2 is stronger than oxygen adsorption capacity, NO2 would take away the electrons from the adsorbed oxygen ions or the conduction band of tungsten trioxide, so that the WO3 surface depletion layer width and the barrier height increase, WO3 conductivity decreased and resistance increased.

The traditional preparation of tungsten trioxide based semiconductor NO2 gas sensor method is a sol - gel method, this method produced a higher sensor sensitivity to nitrogen dioxide, but its response and recovery slow and difficult to control the amount of added concentrated hydrochloric acid. In addition, studies have proposed a gas phase reaction method and improved sol - gel method to obtain the nano tungsten trioxide NO2 gas sensor, which has a very high sensitivity to low concentration of nitrogen dioxide, fast response and recovery speed. In addition, there is also report about the use of thermal spray method to prepare tungsten trioxide gas sensing layer, which shows a good response to the low concentration of nitrogen dioxide gas.

In recent years, physical vapor deposition method is also widely used in the preparation of tungsten trioxide based gas layer, Li Wei and his team uses magnetron sputtering method to prepare the tungsten trioxide film with a small average particle size, large specific surface area, which is significantly improving the sensitivity of tungsten trioxide to nitrogen dioxide and showing a good selectivity; Zhao Yan et used pulse laser sputtering technique to depose tungsten trioxide film, and obtain the triclinic tungsten trioxide film after the heat treatment, which the sensitivity increased with the continually lower of operating temperatures, but the response and recovery time is extended.

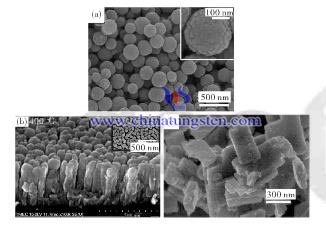

In addition, low-dimensional materials, such as nanosheet, nanowire, nanotube and other tungsten trioxide gas sensors, not only increases the surface area of the gas sensor, but also controls the exposed surface of the material, so that WO3 based NO2 gas sensor has good In response to improve sensitivity.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com