Tungsten Carbide Glass Cutter

- Details

- Category: Tungsten Information

- Published on Thursday, 22 September 2016 17:15

Tungsten carbide glass cutter refers to the material of cutter bit, which is the key part of the glass cutter. Cutter bit has a relatively large angle but very sharp blade, by a glass across the glass surface, the bottom edge will leave a very sharp groove on the glass. The glass surface is then grooved by pulling action, since the bottom is very sharp, there is a big stress concentration, the brittle glass material is easily split along the groove. There are many types of tungsten carbide glass cutter:

1. By the cutter bit material: natural diamond glass cutter, synthetic diamond glass cutter, carbide glass cutter;

2. By the cutter bit material: Aluminum handle glass cutter, red wooden handle glass cutter, plastic handle glass cutter, bronze handle glass cutter;

3. By the function: Multifunctional glass cutter, electroprobe glass cutter, dual-use positioning glass cutter and connected tape glass cutter;

4. By the shape and using: Straight shank, hand-held, T-typed, rotated type and so on.

When using tungsten carbide glass cutter, you should notice that:

1. Cutting 2-3mm plate glass: Use 2mm × 12mm thin wooden ruler, check the cutting size and consider that the gap of 3mm and 2mm incision. Put the size of one side against the glass, grasp the blade end straightly draws back;

2. Cutting 2-3mm plate glass: Except the method above, there is another method that use 4mm × 50mm ruler, the cutter against the ruler. It should be noticed that b brush kerosene on the incision before cutting;

3. Cutting 4-6mm large plate glass: Before cutting, we should put a wad velvet on the working table to ensure the uniform cutting force;

4. Cutting wired glass: Wired glass has rugged cutting surface, it is easy to slip cutting edge, so the force and speed is important in case of bending;

5. Cutting patterned glass: Embossed surface faces down and the method is the same with the wired glass;

6. Cutting frosted glass: It is the same with the cutting method plate glass.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Test Probe

- Details

- Category: Tungsten Information

- Published on Thursday, 22 September 2016 17:10

Due to its excellent performance, tungsten carbide test probe has been widely used in high-precision electronic hardware test and has longer service life than other materials. According to the structure, tungsten carbide test probe can be specifically divided into cantilever probe (blade type, epoxy type) and the vertical probe (ICT series probes, interface probes, micro-series probes, switch probes, coaxial probes, rotator probes, high current probes, semi-conductor probes, battery and connector contacts, wire test probes). Or it can be also divided by electrical test application:

1. Optical circuit board test probe: the test of the circuit board and short circuit before component installation, most of the domestic probe products can replace imported products;

2. Online test probe: Test for PCB circuit board mounted components, the core technology of high-end products is still under controlled by foreign industry, some of probes domestic have been developed successfully;

3. Microelectronic test probe: the test wafer or chip IC detection probe, the core technology is still in control of foreign companies, domestic manufacturers actively involved in research and development, but only a small part of the success of the production.

In order to ensure the measuring accuracy of test probe, we should notice that:

1. Probe length as short as possible: to reduce bending or deflection of the probe on accuracy;

2. Minimum connection point: every time the probe and the extension rod connected together, the equivalent of an additional introduction of a new potential bending and deformation point;

3. Detection ball as large as possible: make the ball / stem clearance maximum, thus reducing the possibility of false triggering due shake, and may weaken the influence of the measured surface unpolished part on the accuracy caused.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide File

- Details

- Category: Tungsten Information

- Published on Thursday, 22 September 2016 16:47

Tungsten carbide file is suitable for mold repairing, polishing and the products with high requirement to grinding precision and durability. It plays an important role in burrs removing and improving the fineness of the surface, which can be widely used in metal works, die-casting plant, refrigerator, washing machine, motorcycle, automobile and other large mold polishing. There are some advantages of tungsten copper file as follow:

1. It can be used in cast iron, cast steel, carbon steel, alloy steel, stainless steel, copper, aluminum and other metals, and marble, jade, bone and other nonmetal machining;

2. Basically can replace small grinding wheel and no dust pollution;

3. Improve the efficiency ten times than hand file;

4. High quality, fineness, can process diverse mold cavity with high-precision shape;

5. Long service life, ten times longer than high-speed steel tool.

In addition, it should be noticed when using tungsten carbide file:

1. Fracture shape: Choose the fracture shape according to the shape of filed parts; when filing the inner circular surface, to select the file or semicircle round file (small diameter workpiece); when filing the surface of inside corner, to select triangular file; when filing the right angle of inner surface, you can choose flat file and square file.

2. Tooth width: Choose according to the margin, the accuracy and the material of the workpiece. Coarse teeth rasp suitable for processing large margin, low dimensional accuracy, geometric tolerances, and surface roughness values large, soft material of the workpiece;

3. Tooth profile: The tooth profile pattern should be chosen according to the materials. When filing aluminum, copper, mild steel and other soft material of the workpiece, the best selection of single-tooth pattern file. It has large rake angle, small wedge angle, large chips flute, sharp cutting edge and other advantages.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gas Tungsten Electrode Arc Welding (GTAW)

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 September 2016 17:28

Gas tungsten electrode arc welding, also known as gas tungsten arc welding (GTAW), is mainly used for casting repair welding, molding constructing and repairing, construction, and copper alloy piping systems constructing and standard weldments welding, allowing welders to precise control weld line and maximize to increase deposited quality. GTAW preferred power type is DC negative (dcen) and also use high-frequency alternating current (achf). The protective gas is usually high purity helium and tungsten electrode is usually to choose sharp-pointed nose. Tungsten electrode extending torch nozzle length should be 1/4 "to 3/8" (6.4 to 9.5mm). Arc length should be maintained at 1/6 "to 3/16" (1.6 to 4.8mm).

GTAW preheat recommendations:

1. Mild steel carbon content less than 0.29% does not require preheating;

2. Medium carbon steel carbon content between 0.3% to 0.59% preheating temperature is between 149 ℃ ~ 315 ℃;

3. Low alloy steel does not require preheating;

4. The gray cast iron preheating temperature is between 204 ℃ ~ 315 ℃, slowly cooling;

5. Ductile cast iron and malleable iron preheating temperature is between 149 ℃ ~ 204 ℃ and after welding should employ annealing;

6. The copper-nickel alloy and silicon bronze does not require preheating and the highest level temperature is 93 ℃;

7. Aluminum bronze aluminum content not more than 10% does not require preheating and the highest level temperature is 149 ℃;

8. Manganese bronze protective gas arc welding preheat temperature is 149 ℃ and shielded metal arc welding temperature (SMAW) is 260 ℃;

9. The preheating temperature of copper is 538 ℃.

Welding current recommendations:

|

GTAW |

Welding Wire Diameter |

DC Negative |

Alternating Current |

|

1/16” |

70-120 |

70-150 |

|

|

3/32” |

120-160 |

140-230 |

|

|

1/8” |

170-230 |

225-320 |

|

|

5/32” |

220-280 |

175-300 |

|

|

3/16” |

280-330 |

200-320 |

|

|

Weldment is nickel alloy or ferroalloy to select smaller value; Weldment is bronze alloy to select intermediate values; Weldment is copper to chose large value; |

|||

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

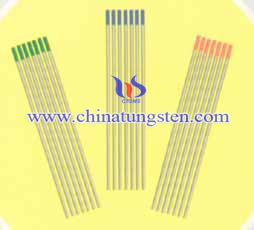

Ecological Material - Multi Composite Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 September 2016 17:25

Multi composite rare earth tungsten electrode is an ecological material. It can achieve low emissions, no pollution, which can completely replace the serious environmental pollution thorium tungsten electrode used in welding, plasma welding, and spraying and cutting technical and as key heat source material used in metallurgical industry. Currently, the total annual world consumption of tungsten electrodes can up to thousands of tons and the market demand increasing with economic steady development the amount of consumption continues to rise, where thorium tungsten electrode consumption accounts for more than 70%. Thorium is a natural radioactive element and the half-life period is more than 1.39x 1010 year, so the thorium tungsten electrode is harm to human health and environment. As countries increasing attention to environmental issues, will significantly restrict the production and use of thorium tungsten electrodes.

Multi composite rare earth tungsten electrode has low work function, high melting point, good high temperature mechanical properties and chemical stability and there are abundant raw materials, thus becoming the new alternative material of thorium tungsten electrode. In multi composite electrode, rare earth oxides can refine tungsten grain size to improve the performance of the electrode. After welding testing found it has better arcing performance and anti-burning properties. Besides, the arc static characteristic curve is small than Th-W electrode indicated that it has lower surface electrode work function and electrons are easily escape from the surface, which has better welding performance. Multiple composite rare earth tungsten electrodes at 1300 ℃ the effective work function is 2.76eV and Th-W electrode effective work function is 3.08eV, so composite electrode has low thermal electron emission capability. Electron work function has certain impact on the arc performance. At the beginning of arcing and during arcing, the electrode surface has not been heated to enough temperature, so it can not work as a hot cathode at the first. If the electrode surface has low work function, then the electrode to produce the hot electrons temperature is lower and the electrode is easy to produce thermionic emission. At certain voltage the welding circuit current to generate arc discharge current required time is less, which is arcing easier.

Through the above indicators we will see, multiple composite tungsten electrode is an ecological material. Compared to the thorium tungsten electrode it has good weldability and it can replace Th-W electrode as new welding materials.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

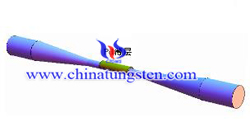

Tungsten Copper Gas Vane

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 September 2016 17:17

As a special wing in rocket jet, tungsten copper gas vane represents the thrust vector controlling technology. And it is indispensable in AAM active duty and in studying. Therefore, it has many strict design requirements as follow:

1. It should have a constant value close enough to lift the gradient to meet the maximum lift control requirements;

2. Differential gas vane should meet the requirements of rolling control;

3. Ensure small resistance to reduce the loss of engine thrust;

4. Rudder hinge moment and change the entire duration of the work to be relatively small in order to reduce the power requirements of the steering gear;

5. Gas vane small as far as possible, but should meet the strength and rigidity requirement. And reasonable location is convenient for attached parts designing and installation;

6. It can not produce mechanical interference when gas vane deflected to the maximum angle.

Based on the ablation mechanism, it can specifically divided into:

1. Effect of particle erosion: A large amount of high energy solid particles in gas stream impact the surface of gas vane intensely, which partial surface reach high temperatures in a short time and accelerate the material ablation. Besides, the surface roughness increases will lead to uneven distribution of the flow field to form a vortex, and lead to the accumulation of localized heat;

2. Mechanical erosion effects: the presence of a thermal expansion coefficient difference between the substrate materials caused by thermal stress generated when it exceeds the combined strength of the gas flow at supersonic peeling effect occurs.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

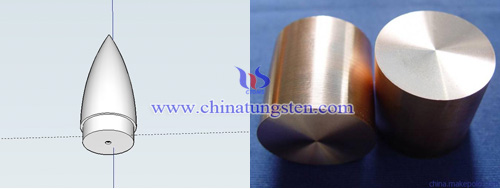

Tungsten Copper Nose Cone

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 September 2016 17:11

Tungsten copper nose cone at the front of a rocket or missile, when it enters the atmosphere at supersonic speed, will have a strong head detached bow shock. It can protect the payload and endure the large temperature difference and high-speed particle erosion at the same time.From the structure of the rocket, a rocket includes a high thin cylinder, made by sheet metal. The cylinder stores the rocket engine's fuel and refueling tank inside, and rocket propulsion engine is provided at the bottom of the cylinder. In the upper part of the cylinder is fitted with a hollow cone streamlined, connected to the base of the cone cylinder, cone tip upwards. This shape of the cone of the rocket exposed to air cross section of minimum cross-sectional area is reduced to reduce the energy required for rocket discharging air consumption. Generally, the payload of manned spacecraft is placed in the top of the rocket nose cone. It is called as payload fairing cone in space technology, which plays an important role in protecting the payload after rocket ignition and prevent the rocket from destroyed by the enhanced wind of rocket accelerating.

And there are some ablation mechanism of tungsten copper nose cone. The ablation mainly includes thermal chemical ablation and mechanical erosion. Ablative heat characteristic is the use of short, tungsten, copper nose cone is a typical heat sink material, which is adjusted by the material properties of its own, is evaporated and turned away most of the copper in the heat, so it can keep the allowed temperature inside the craft. In addition, the ablation mechanism can be divided into sublimation, melting and charring, which has a cross-phase relationship of the triple point, at high temperature and pressure, carbon homogeneous melting and evaporation occurs interaction phenomenon exceeds the triple point.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Porous Silicon Substrate WO3 Nano-Thin Film Gas Sensor

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 September 2016 10:23

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Hydrogen Tungsten Trioxide Optical Fiber Sensor

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 September 2016 10:29

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

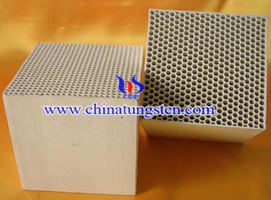

Important Indicators of Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 09 September 2016 17:45

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com