Tungsten Copper FGM Flexural Strength and Thermal Conductivity

- Details

- Category: Tungsten Information

- Published on Friday, 20 January 2017 17:25

Tungsten copper FGM flexural strength refers to the capability of resistance to external force. Generally, it uses three-point bending test or four-point test method for evaluation. Mechanical properties: The performance of the material by external force; Stress: The reaction material inside to external force. The magnitude of the stress by the following equation: stress (δ) = Effect (F) / unit area of material (A), in units of Pa;Strain: The deformation of material caused by external force. Strain magnitude represented by the following equation: strain (ε) = length change (△L) / initial length (L);Tensile stress, compressive stress, shearing stress.

The flexural strength of W-Cu gradient composites with different layers as the pressure-receiving surface on different surfaces is the flexural strength of different surface. Three-layer and four-layer structure of the gradient composite material to use W-50Cu for the bearing surface, the flexural strength obtained higher than that with W-20Cu as the pressure bearing surface, which shows that the mechanical properties of FGM show a gradient change along the direction of Cu content increasing. In addition, four-layer structure of the gradient material has higher interface bonding strength and smaller residual stress so the resistance to destruction is much better.

Tungsten copper FGM thermal conductivity normally refers to the vertical temperature gradient down 1 ℃ / m, the heat through unit horizontal cross-sectional area per unit time, which is the important measure of FGM material and generally expressed by λ or K.Tungsten copper FGM thermal affected by the pressure barely, and the main influencing factors include one is the density, the lower the density, the higher porosity, the thermal conductivity decreases; other is Cu forms ideal net structure in W matrix, which can provide good heat dissipation channel for the material and remarkably improve the thermal conductivity of tungsten copper composite material. y densification and microstructure analysis of tungsten copper FGM, it can be found that the densities of the three-layer and four-layer structure graded materials have reached a high level (198W / (m • K), 202W / (m • K) ), Are between the package layer and thermal layer thermal conductivity between the access to higher thermal conductivity.The study of tungsten copper FGM thermal conductivity provides solid theoretical foundation for new thermal conductivity of materials and new insulation materials and research, which also gives a strong theoretical and material support for space exploration activities and marine exploration activities in the future. Due to high thermal conductivity and excellent mechanical properties, it can perfectly solve the heat dissipation of electronics next few years.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper FGM Thermal Shock Resistance

- Details

- Category: Tungsten Information

- Published on Friday, 20 January 2017 17:18

Tungsten copper FGM thermal shock resistance is also called as thermal stability, thermal shock stability or resistance to temperature abruptness. It is an important indicator for evaluating the resistance of damage when it endures rapid temperature change. The closer the test values are, the higher the precision is.The main influencing factors of tungsten copper FGM thermal shock resistance include CTE (Coefficient of Thermal Expansion), thermal conductivity, elastic modulus, material inherent strength, fracture toughness. Generally, the smaller CTE, the less the volume change caused by the temperature change, the less the corresponding temperature stress, the better the thermal shock resistance; the higher the inherent strength of the material, the greater the strength to withstand thermal stress without damage, thermal shock resistance is better; the larger the elastic modulus, the smaller the elasticity, the smaller the elastic deformation of the material can not alleviate and release thermal stress, which is not good for thermal shock resistance.

There are some basic test methods:

1. Straight brick water quenching method in China (YB376). (200 to 230 mm) X (100 to 150 m) K (50 to 100 mm) was inserted into a furnace preheated to 1100 ° C for 50 minutes and then quenched in water at room temperature for 3 minutes and then dried. The thermal shock resistance was characterized by the number of thermal cycles in which the end face was broken by half;

2. Long strip test method in China (YB4018). The sample (230mm x 114mm x 31mm or 230 mm x 65mm x 31mm) to a surface as the heating surface, in the hot plate from the room temperature to a prescribed rate heated to 1000 ℃, for 30min, and then quenched in the air. The degree of damage was evaluated by the percent change of flexural strength before and after thermal shock. The bending strength retention ratio of each brick is calculated by the following formula: Rr = Ra / Rb × 100%, Rr - Retention strength (%), Ra-bending strength (MPa) Fracture strength of specimens before thermal shock.

In addition, there is United States panel test method (ASTMC38), long sample test method (ASTMCll00) and the European Refractory Manufacturers' Association's Cylindrical Sample Water Quenching (PRE / RS-1).

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper FGM Principle

- Details

- Category: Tungsten Information

- Published on Thursday, 19 January 2017 17:49

Tungsten copper FGM principle makes the interface of the composition and organization have a constant change by controlling micro elements. Its characteristics include:

Tungsten copper FGM principle makes the interface of the composition and organization have a constant change by controlling micro elements. Its characteristics include:

1. The composition and structure of the material show a continuous gradient;

2. There is no obvious interface within the material;

3. The properties of the material also show a continuous gradient change.

Tungsten Copper FGM Particle Co-sedimentation

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 January 2017 17:35

At present, tungsten copper FGM mainly uses laminated sintering, but it does not eliminate internal interface between layers. So regardless of the operability of the preparation process, or thermal stress relaxation, it has great defects. And other methods, such as CVD (Chemical Vapor Deposition), high temperature plasma spraying, although can improve the internal interface to some extent, it is unstable and difficult to achieve gradient design. Tungsten copper FGM particle Co-sedimentation can achieve a continuous arrangement of heterogeneous particles and component transition, Improve or eliminate the internal macroscopic cross-section of the material, which is beneficial for structural controlling of FGM.

The settling velocity of the spherical particles under the action of gravity is related to the size and density of the particles. It can be speculated that under certain conditions, the same kind of powder sedimentation, the large particles of rapid settlement; and for different types of powder, larger particle and high density has rapid settlement. Therefore, the settling behavior of the two powders can be controlled by adjusting the sedimentation parameters and selecting the proper powder characteristics for the given two kinds of powders, and the gradient material with continuous distribution of the components can be prepared. FGM by this method has many advantages, such as simple operation, gradient material with good scale so that it has been becoming one of important developing direction of FGM field.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Wire Properties

- Details

- Category: Tungsten Information

- Published on Thursday, 12 January 2017 20:14

Tungsten wire is often used in incandescent filament, because of its properties, such as high temperature performance, good room temperature performance and wire diameter consistency character.

Tungsten wire is often used in incandescent filament, because of its properties, such as high temperature performance, good room temperature performance and wire diameter consistency character.

High temperature performance

Tungsten has high temperature performance and tungsten filament operating temperature is between 2300 ~ 2800 ℃. Early, tungsten filament lamp life is short, and it is mainly for that the tungsten filament operating temperature exceeds its recrystallization temperature, resulting in filament sagging phenomenon, leading to lamp failure.

Tungsten Wire Images

- Details

- Category: Tungsten Information

- Published on Friday, 30 December 2016 12:00

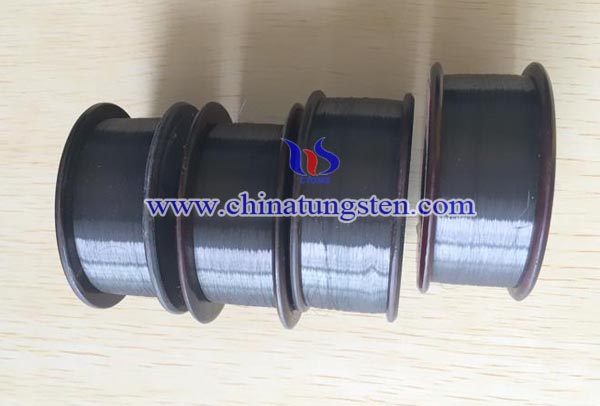

Black tungsten wire is tungsten wire with graphite surface.

Cleaned tungsten wire is removing the graphite surface from black wire, and can be cleaned by alkali washing.

Doped tungsten wire is doped K or other elements to improve pure tungsten wire properties.

Non-sag tungsten wire is created to be used as car and motorbike lamps filaments.

Straightened tungsten wire is tungsten wire processed by straightening for easier cutting and using.

Stranded tungsten wire is tungsten wire stranded by two single wire, three, or more. The type of 3+1 is stranded by three tungsten wires and one Al wire.

Tungsten heater is made of single tungsten wire or stranded tungsten wire for vacuum coating.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper FGM Dry Spraying + Gradient Sintering

- Details

- Category: Tungsten Information

- Published on Thursday, 29 December 2016 15:31

Tungsten copper FGM dry spraying + gradient sintering main process: mixing ratio of tungsten and copper mixed powder into the ion gas chamber, the use of high-frequency jet to make the raw material powder into ultra-fine particles and cooling; and then the resultant coating is put together with the matrix into a self-made special sintering furnace, and the sintering process is carried out using the temperature gradient. In order to control the shrinkage difference between matrix and coating during sintering process, it is necessary to add a trace element in the preparation process to control the contraction of the two to reach the same. The ultrafine particles in the process can reduce the sintering temperature of the products, the gradient coating crystal is fine so that the coating performance greatly improved, but the experimental process is more complex.

Dry-type spray chamber is mainly composed of dynamic and static pressure chamber, spraying work room, separation chamber and exhaust system. The common method is plasma spraying, which can obtain alloy-based composite gradient lubrication coating without water. The graded structure makes the adhesion of the coating and the substrate significantly improved. Electro-deposition method belongs to wet-type, it has many advantages: 1. without high temperature, high voltage, high vacuum, simple operation; 2. current as the reducing agent process conditions easy to control, easy to adjust the gradient requirements; the coating composition and structure can be effectively controlled.

In addition, the settling velocity of the spherical particles under the action of gravity is related to the size and density of the particles. It can be speculated that under certain conditions, the same kind of powder sedimentation, the large particles of rapid settlement; and for different types of powder, larger particle and high density has rapid settlement. Therefore, the settling behavior of the two powders can be controlled by adjusting the sedimentation parameters and selecting the proper powder characteristics for the given two kinds of powders, and the gradient material with continuous distribution of the components can be prepared. FGM by this method has many advantages, such as simple operation, gradient material with good scale so that it has been becoming one of important developing direction of FGM field.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper FGM Laser-heating Synthesis

- Details

- Category: Tungsten Information

- Published on Thursday, 29 December 2016 15:14

At the beginning of 1990s, FGM (functionally graded material) has developed rapidly and additional temperature laser scanning sintering process has been introduced in FGM process. It solves the problem that the difference of sintering temperature and shrinkage of different composition gradient layers, which is difficult to conventional sintering technology furnace constant temperature sintering method. In addition, it shows laser heat source temperature gradient sintering non-polluting, high efficiency and the advantages of modernization.

However, the application of laser in tungsten copper FGM material research has just started, the researchers used a micro-thermocouple embedded successfully measured the sintering temperature of laser sintering of tungsten-copper gradient material distribution. In general, W-Cu gradient functional materials with no interfacial changes can be obtained by laser sintering process with large spot size; sintering process of tungsten - copper alloy synthesized by laser heating under the thermocouple dynamic measurement was analyzed, and the difference of sintering temperature and shrinkage difference of FGM were solved by laser heating; The microstructure of tungsten copper FGM shows macroscopic microstructures changes; the micro-hardness of the tungsten - copper functionally graded material synthesized by the laser - sintering process of the large - plate laser is gradient distribution, which satisfies the linear distribution rule; and laser heat synthesis process should be under inert gas such as argon or neon gas.

In addition, tungsten copper FGM mainly uses laminated sintering, but it does not eliminate internal interface between layers. So regardless of the operability of the preparation process, or thermal stress relaxation, it has great defects. And other methods, such as CVD (Chemical Vapor Deposition), high temperature plasma spraying, although can improve the internal interface to some extent, it is unstable and difficult to achieve gradient design. Tungsten copper FGM particle Co-sedimentation can achieve a continuous arrangement of heterogeneous particles and component transition, Improve or eliminate the internal macroscopic cross-section of the material, which is beneficial for structural controlling of FGM.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper FGM Slurry Casting

- Details

- Category: Tungsten Information

- Published on Thursday, 29 December 2016 14:58

Tungsten copper FGM slurry casting mixes raw material into slurry and injected into mold to be dried to continuously control the proportion of the slurry. It belongs to non-pressure forming process and originated in ceramic industry firstly until the 1940s has began used in the tungsten, molybdenum, carbide and cermets and other hard brittle powder forming. Now, it has been used in fiber-reinforced super-alloy such as tungsten-alloy fiber reinforced nickel-base super-alloy, jet engine components such as turbine blades and gas chamber components.

Tungsten copper FGM slurry casting process includes three steps of preparation of slurry and mold, pouring, injection of drying. The slurry consists of metal powder or fiber and mother liquor. The requirement of the slurry is a certain concentration (powder weight accounted for 40% to 70%); good wettability of powder and mother liquor and the surface of the particle does not adhere to the gas; slurry evenly suspended without sedimentation. Additives have a variety of ingredients, including binders, dispersants, suspending agents (stabilizers), degassing agents and titrants. Binder can be bonded powder, improve the strength of castings, commonly used sodium alginate, polyvinyl alcohol. Dispersants and suspending agents prevent particle aggregation and improve the wettability of the powder with the mother liquor to form a stable suspension.

The influencing factors of tungsten copper FGM slurry casting include metal powder characteristics (such as granularity, solid-liquid ratio, pH value, additives), heat treatment properties (the rate of drying of the injection mold in and after the mold, and the porosity of the mold). In order to get different types of castings, slurry casting with solid casting and hollow casting two processes. The former using the reservoir or other methods to replenish the slurry, so that the mold is completely filled with slurry to get solid injection; the latter is to control the standing time of the slurry, when the mold wall on the formation of the powder layer thickness is appropriate, the extra slurry poured out to obtain hollow injection.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper FGM Spray Deposition

- Details

- Category: Tungsten Information

- Published on Tuesday, 27 December 2016 17:52

Tungsten copper FGM spray deposition is also called as spray forming, which a kind of advanced forming technology develop in nearly 30 years and uses rapid solidification to prepare metal blanks or semi - finished products directly. It consists of molten metal gas atomization, atomization droplet deposition and other continuous process.

Spray rolling: Spray deposition forms a continuous strip product followed by hot rolling or cold rolling;

Spray forging: The aim is to produce a hot-forged injection-molded blank, or to extrude the blanks after spray forging;

Centrifugal spray deposition: The molten metal is atomized by centrifugation, deposited on a cold substrate, removed from the substrate by the formation of large pipes;

Spray coating: The coating is bonded to the substrate and peen at the same time can manufacture fully dense, thermal processed and unstressed deposits.

Tungsten copper FGM spray deposition is suitable for manufacturing large thin-walled parts and access to continuous strip, which has fine-grain, excellent properties, save energy and low costs.

The principle of tungsten copper FGM spray deposition: The molten metal flows out through the draft tube and is broken by the high-speed airflow at the outlet of the atomizing nozzle, and is atomized into a small dispersed droplet jet; atomized droplet jets are accelerated by the momentum of the high velocity gas flow and are strongly exchanged with the gas stream; before reaching the deposition surface, droplets less than a critical size solidify into solid particles, the larger size is still liquid, and the intermediate size droplets are semi-solidified particles containing a proportion of the liquid phase; these large and small droplets of different solidification degree impinge on the deposition surface at high speed and deposit, spread, accumulate and fuse together on the deposition surface to form a thin semi-liquid layer, and then solidify and crystallize, and gradually deposit and grow into a large compact metal solid deposit. In a word, it is composed of two steps, one is atomize the alloy liquid into fine droplets by spraying, and they partially solidified after flying; the other is deposits on the base before completely solidified and further cooling for rapid solidification.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com