Tungsten Copper Contact for Arc Extinguisher

- Details

- Category: Tungsten Information

- Published on Monday, 20 March 2017 17:32

Introduction

Tungsten copper contact for arc extinguisher mainly used in extinguishing arc when switch on/off in case of arc erosion. According to working principle, it can divided into traditional arc extinguisher and electronic arc extinguisher.

Principle

Tungsten copper contact for arc extinguisher mainly used in electronic arc extinguisher, used to eliminate the inductive load in the loss of electricity generated when the acoustic power to suppress the resulting interference, to prevent the drive components or contacts from damage. It can inhibit the electromagnetic interference by the spark to keep work stable and extend service life. Tungsten copper contact for arc extinguisher has small size, light weight, low power consumption and is suitable for high operating frequency. Electronic arc extinguisher can effectively avoid the contactor damage caused by arc sputtering and improve the electrical life.

Notice

1. Wiring should ensure that it does not loose, poor contact will significantly reduce the arc extinguishing effect;

2. Ensure used within the rated voltage range, or it will be burn easily;

3. Design and installation, the lead wire should be as short as possible and near the coil (30mm in general);

4. Notice the polarity, reversed contact will burn out arc extinguisher.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

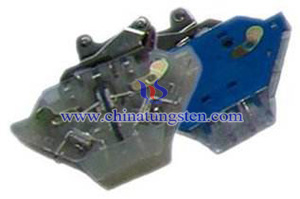

Tungsten Copper Contactor

- Details

- Category: Tungsten Information

- Published on Monday, 20 March 2017 17:30

Tungsten copper contactor can quickly cut off the exchange and DC main circuit and can be frequently connected with the high current control (up to 800A) circuit device. So it often used in the motor as a control object can also be used to control the factory equipment, electric heater, machine tools and machine tools all kinds of electric power units and other power load. It can not only turn on and off the circuit, but also has a low voltage release protection, suitable for frequent operation and remote control.

When the contactor coil is energized, the coil current generates a magnetic field. The magnetic field generated by the static core to produce electromagnetic attraction to attract the core, and drive AC contactor action, normally closed contact open, normally open contact closure, the two are linked. When the coil is out of power, the electromagnetic attraction disappears, the release of the role of the release armature spring, the contact recovery, normally open contact open, and normally closed contact closure.

The AC contactor utilizes the main tungsten copper contact to control the circuit and the auxiliary contact to turn on the control loop. The main contacts are normally open contacts, and auxiliary contacts are often two pairs of normally open contacts and normally closed contacts, small contactors are often used as an intermediate relay with the main circuit. AC contactor contacts, made of tungsten copper alloy, have good electrical conductivity and high temperature ablation. AC contactor power from AC movement with the core coil with the magnetic field generated by the electromagnetic core from the two "mountain" shaped silicon steel sheet stack, one of the fixed core, with a coil, the operating voltage can be a variety of options. In order to stabilize the magnetic force, the core of the suction surface with short-circuit ring.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact for Magnetic Blow Breaker

- Details

- Category: Tungsten Information

- Published on Monday, 20 March 2017 17:27

Tungsten copper contact for magnetic blow breaker uses the role of magnetic field to extinguish arc. Magnetic field is usually generated by the breaking current itself, the arc is a magnetic field into the arc chute slit, and make it elongated, cooling, until disappear finally.

Tungsten copper contact for magnetic blow breaker uses atmosphere as a medium, with heat-resistant ceramic or mica glass for the arc, the electrical life is long, can adapt to the frequent operation of the occasion. In the breaking process, the arc resistance increases rapidly, can improve the power factor; resulting in the smallest over-voltage, excellent breaking characteristics. Magnetic blow circuit breaker has safe operation and easy maintenance, but compared with other circuit breakers, its structure is complex, bulky, high cost, generally only apply to 20 kV voltage level.

According to the principle of magnetic blowing, it can be divided into electromagnetic and arc solenoid contacts.

Electromagnetic type: Use the breaking current runs through the magnetic coil and produce blowing magnetic field to extinguish arc. This structure needs to be specially set magnet coil and magnetic pole plate and other components, the structure is more complex and bulky, breaking performance is poor, in the early magnetic blow circuit breaker has been widely used;

Arc solenoid type: Appeared in the 1960s, the principle is the use of insulated arc extinguishing plate and a small arc angle (mounted on the lower end of the arc-shaped pieces of U-shaped steel) arc division to form a continuous coil arc and generate strong magnetic field, the rapid movement of the slit in the slit until extinguished.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Copper

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:32

Tungsten carbide copper are using high quality tungsten carbide powder and oxygen free copper through pressing forming, High-temperature sintering and copper infiltration process, to ensure the purity and accuracy of products. The arc breaking performance and conductivity are good, the thermal expansion is lower and high-temperature resistance is excellent.

It is a kind of refractory metal material prepared by pressing, sintering and infiltration, this material has excellent anti arc erosion and high capacity. It uses the special technology to prepare, it not only has the characteristics of high melting point, strength, hardness and boiling point, at the same time, it also has the advantages of good conductivity, low thermal conductivity and low contact resistance.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Antimony Bismuth Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:29

In the tungsten copper antimony bismuth alloy, because radium is a shiny metal with activity chemical property, exposure to air can rapidly react with oxides and nitrides, then react with water to produce hydrogen oxide radium.

The infiltration method can be used to prepare tungsten copper antimony bismuth alloy, during the preparation process because of the radioactivity of Ra, Ra will volatilize, melting point and boiling point are lower. So it is not suitable to use the infiltration method. The performance and density of powder metallurgy products are lower, so the activation treatment of powder is to make it easy to sinter to obtain high density samples.

In order to prevent Ra metal oxidation and can be prepared in the atmosphere, therefore, Ra is usually regarded as impurity elements with Ra oxide instead of metal Ra alloy. Generally speaking, tungsten copper antimony bismuth alloy is prepared by the activated sintering of tungsten copper. In order to prevent the problem of radium oxidation, in the form of oxides to add tungsten copper antimony bismuth alloy.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Plasma Spraying of Tungsten Copper

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:26

Plasma spraying of tungsten copper alloy is carried out by plasma arc, plasma arc have high temperature, good arc stability and large current density. It is one of the rational processes for the preparation of tungsten copper heat sink materials.

Plasma spraying of tungsten copper spraying a layer of coating on the surface of artificial bones can enhance affinity and strengthen artificial bones. It can heat the material such as metal or alloy into molten state, spray the surface of the part treated to be firmed, In addition, plasma spraying technology makes the surface of the material with radiation, sealing, wear and corrosion resistance and thermal insulation performance.

Characteristics of plasma spraying method of tungsten copper:

1.The spray particle has high efficiency, good adhesion and high density.

2.Because of the high temperature, it suitable for spraying high melting point materials.

3. The processing of spraying contains inert gas, which can be used as a protective layer so that it is not easy to oxidation.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Melting Point

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:23

The influencing factors of tungsten copper melting point:

1.The tungsten copper melting point usually refers to under atmospheric pressure, the melting point varies with pressure, it can divided into two different situations, When the pressure increases, the melting point increases when the pressure increases, but the liquid is different from the tungsten copper, the melting point is reduced when the pressure increases.

2. Tungsten copper products are generally have impurities, even a small amount of tungsten copper, the change of its melting point are very large.

In nature, the melting point of tungsten copper is the coexistence of tungsten and copper in solid and liquid at a certain temperature. In the same crystal, melting point relate to pressure, under a certain pressure, the melting point and freezing point are the same, when the volume expansion of the material in the melting pressure, its melting point increases when the pressure increases.

The melting point of tungsten copper is measured by micro melting point method and capillary method. However, it is usually measured by professional measuring instrument in practical.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano Tungsten Copper

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:20

The Nano tungsten copper alloy has different specific properties compared with conventional crystalline materials, the preparation of Tungsten copper with full densification and high mainly lies in the extraction of tungsten copper composite powder in nano structure. There are spray drying method, mechanical alloying method, sol-gel method and thermo mechanical method, etc.

The influencing factor of the sintering densification of nano tungsten copper:

1.Influence of forming pressure.

2.Influence of sintering temperature and holding time.

Influence of mechanical alloying method.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Nozzle

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:16

Tungsten copper nozzle has a long service life, which is several times of common copper material, and it greatly reduces the cost of production. Because of the relatively high conductivity, the high temperature by welding is quickly transferred; the core hardness and wear resistance of the conductive nozzle are continuously strengthened. Its coaxiality and finish are very high in order to meet the strict requirements of the military field. The nozzle usually mounted at the end of the welding equipment to guide the welding wire, the weld quality is high, less smoke and no arc.

Because of the use of electric current and the electric field intensity is high, the conductive nozzle material which is used in the field of military high not only been needed for good conductive and thermal conductivity, the hardness, strength and electric resistance of ablation need to be improved. Compared with the copper and chromium zirconium copper electrode, in spite of the high current environment, tungsten copper nozzle can also keep a good performance; the arc ablation resistance is strong to increase the service life. Compared with the copper and CuCrZr nozzle, it is easy to occur adhesion during welding, bonding wire and conductive nozzle, spatter plug the nozzle which leads to the failure of conductive nozzle.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Spray Drying of Tungsten Copper Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:12

The spray drying process of tungsten copper consists of three stages: spray drying, preparation and hybrid of original liquor and conversion of fluidized bed.

This method is used to prepare WC-Co, W-Ni-Fe and various tungsten copper alloy and nano composite powder. The comprehensive mechanical properties of tungsten copper prepared by the method are obviously improved, and the service life is three times higher than that of conventional products, the process is easy to operate, no impurities and has broad prospects.

The powder obtained by this process can be converted into metal composite powder by fluidized bed, mixing a variety of metal salt solution, quickly injected into the drying chamber through the nozzle to obtain metal salt particles, roasting it, ultrafine particles of nano crystalline oxide composite powder precursors were obtained. Under certain conditions, the precursor powder is obtained through reduction or carbonization to obtain alloy composite powder or carbide.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com