Cold Rolling Tungsten Copper Sheet

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 March 2017 11:06

The cold rolling process of tungsten copper sheet not only has the advantages of low energy consumption, low equipment investment and high production efficiency, but also can rapidly improve the cold working plasticity of tungsten copper alloy.

Nowadays, the processing method of tungsten copper has lots of problems. For example: long production cycle, high energy consumption, most using equipment is the high power processing equipment, high investment, etc. The cold rolling of tungsten copper sheet not only can solve the problem of low energy consumption, but also can enhance productivity, shrink area, improve the processing plasticity of tungsten copper.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Counterweight

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:30

Tungsten copper counterweight block is widely used in weapons, aerospace and ships, tungsten copper provides a lateral force for the sailboat, as a military weapon, the size tolerance of it is smaller, high resistance to heat treatment and high mechanical properties. In aerospace, it is often used in gyroscopes and aircraft counterweight, the high density of tungsten copper alloy products greatly reduces the physical size of the components and it easy to increase sensitivity and control weight distribution, but it should be noted that in aerospace, there have higher requirements of the density and mechanical.

Advantages of tungsten copper alloy counterweight block:

1. It improves tungsten plasticity because of contain copper.

2. Easy molding.

3. Density, uniform structure.

4. High hardness and tensile strength.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Tail Rudder

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:27

Tungsten copper tail rudder can be divided into two types:

1. Cross tail rudder: Four rudders is the cruciform layout, because it is suitable for the submarine activities, the rudder of the horizontal arrangement is larger and the force bearing area is smaller than that of the tail rudder with a cross shaped layout, it is not easy to break when come across ice breaking.

2.X tail rudder: It usually less than or equal to the size of the diameter of the submarine, X shaped layout, smaller size, compared with cross tail rudder, it is safer and less prone to damage.

Effect: On the one hand to provide stability for aircraft, to ensure the balance of the aircraft, control the fly of plane. On the other hand, with the help of the aileron to produce centrifugal force to complete a large angle steering. It can adjust the horizontal and vertical lifting capacity, etc.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper - Rocket Throat

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:24

Tungsten copper is a kind of material which can be used as lining material, ceramic matrix composites and reinforced material, the thermal shock of throat lining mainly occurs at the moment of ignition, the tungsten copper material is made of tungsten infiltrated copper, not only because of its high density, hardness, strength, the good conductivity and thermal conductivity of copper, at the same time, the melting point of tungsten and copper is different, a large amount of heat is taken away by the evaporation of copper, which leaves the hard tungsten to ensure the stability of throat lining.

The principle of tungsten copper rocket throat:

1. Gas energy produced by combustion chamber through nozzle of solid rocket motor by controlling exhaust expansion control the expansion of the exhaust effectively into kinetic energy.

2.The main role of throat lining is limiting throat area

3. Commonly used metal powder for rocket engines, as a high energy propellant combustion, high temperature burning rate of air entrained solids scour throat, severe erosion of throat lining will directly affect the engine thrust and efficiency.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact Used in High Voltage Switch

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:21

According to different arc extinguishing medium, tungsten copper contact in the high voltage switch can be divided into:

1. Oil circuit breaker contact.

2. Magnetic blow circuit breaker contact.

3. SF6 breaker contact.

4. Air circuit breaker contact.

5. Solid gas circuit breaker contact.

6. Vacuum circuit breaker contact.

The main function of it is to cut off, close the no-load current and load current in the high voltage circuit, through relay repair system failure. When loading on, the bounce of the contact causes the temperature of the surface rise continuously and the pulling arc is generated between the contacts.

The principle of it is when the switching load is switched on, ensure the contacts in the closing contact,meanwhile shortening the arcing time of the switch contact. In order to make the contact bounce, be sure to exert a great deal of pressure on the contact so as to cause a greater impact.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper High Voltage Switch

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:18

Tungsten copper alloy is widely used in high voltage switch, lightning arrester and high voltage vacuum load. It is not only small in size, but also widely used in flammable, explosive, humid and corrosive environment. Tungsten copper is widely used in high voltage switch, lightning arrester and high voltage vacuum load. It is not only small in size, but also widely used in flammable, explosive, humid and corrosive environment.

The special technology of vacuum degassing, infiltration and so on is needed. In high pressure, the special technology of vacuum degassing, infiltration and so on is needed in high pressure switch. The resistance to arc erosion, gas content and hot electron emission is limited.

Main properties in high voltage switch:

1. Higher demand for arc erosion.

2. Request high fusion welding resistance.

3. Small cut-off current.

4. Small gas content.

5. Low thermal electron emission.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Heat Sink

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:14

Tungsten copper heat sink is a part of electronic packaging technology, because of the low expansion property of tungsten and thermal conductivity of copper is higher, the use of tungsten copper coefficient of thermal expansion and conductive thermal conductivity of materials to facilitate the use of materials.

Tungsten copper heat sink convenience for optoelectronic devices and cooling electronics convenience, on the one hand, in a light emitting diode and a high power laser, the physical design of the tungsten copper electronic package is convenient for cooling the peripheral fluid (the surface area of the air contact is increased); On the other hand, in the graphics processor and the computer central processor, the heat sink plays an important role in the final junction of the thermal interface material and the basic attachment method. The heat dissipation performance of heat sink can be determined by test attribute value.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What is Tungsten Copper Plate

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:10

Tungsten copper plate properties: it has good plasticity and high electrical conductivity, its electrical processing speed is relatively fast and easy to machining.

The production:

The technological process of tungsten copper plate is mainly formed by mixing powder, pressing, sintering and infiltration. Make tungsten copper powder press forming before liquid phase sintering. The material prepared by the mixed powder is far inferior to the activated sintering, mechanical alloying and oxide reduction. In order to improve the densification of tungsten copper alloy, it should through nano powder to improve the sintering activity. However, the sintering of nickel will make the electrical and thermal conductivity decrease rapidly make tungsten copper is difficult to produce.

Use of tungsten copper plate: Tungsten copper plate is usually used in electrode material, electric shock material, welding material and guide material. As electrode material, it is widely used in thin electrode discharge machining and high hardness materials; As welding materials are used in radio resistance and submerged arc welding machine; In order to play a guiding role in the protection of various wire rolling.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

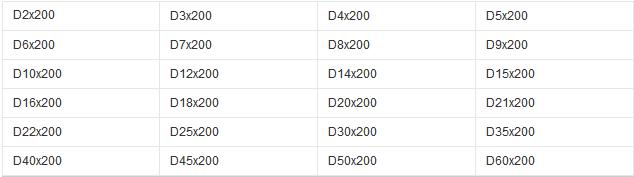

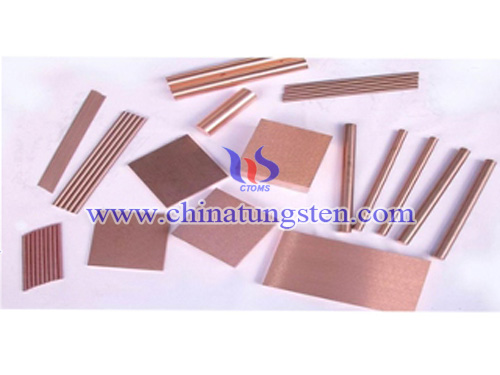

Tungsten Copper Rod

- Details

- Category: Tungsten Information

- Published on Monday, 13 March 2017 16:01

Tungsten copper rod are commonly used in EDM molds, its advantage are as follows:

1. The internal structure of tungsten copper rod is even

2. Tungsten copper rod has a long service life and high hardness

3. Because of high metal removal rate and conductivity, tungsten copper rod production capacity will continue to improve.

4. The mould has high surface finish and high density.

Tungsten copper rod specifications: (unit:mm)

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Types

- Details

- Category: Tungsten Information

- Published on Friday, 10 March 2017 14:07

Tungsten copper alloy have a variety of types, different types have different characteristics, so that it can be used in different products.

1. Tungsten copper electrical materials: Mainly divided into electrical contact and electrical processing materials.

1)Electrical contact material: It is one of the most important kinds of electrical materials with high resistance to arc erosion and welding resistance, as electrical contacts, electrical contacts and electrodes in instrument, applicable to all kinds of high and low voltage switchgear. The maximum amount of tungsten copper material containing 20% to 40%, electrical contacts is the largest class, the utility model is mainly used for medium, high voltage and high current switching devices.

2) Electrical material: Refers to the electrode and mold materials used in resistance welding, electric riveting and electric upsetting. Using more tungsten copper materials for meeting the requirements of EDM, ensure the machining accuracy.

2. Armor materials: Tungsten copper materials can be used as armor material, also known as liner. This type of liner was first made of red copper and was widely used. It should improve the penetration ability in order to increase the cover unit quality, Develop unit quality of tungsten cutting liner material which is larger than copper. In an ideal situation, it is about 30% higher than the penetration ability of copper. Use it to make a cup or funnel, inversion in the front end of a cartridge, depending on the temperature and pressure of the powder, the cover is changed to form a jet.

3. Instantaneous high temperature material: It can be used at temperature close to the melting point of tungsten and slightly above the melting point of tungsten, it is an important and special tungsten copper which can complete the mission in a few seconds to 200 seconds. The most important properties of the instantaneous high temperature materials are ablative and thermal shock resistance, this material is mainly used for the manufacture of high temperature components of spacecraft, such as the rocket nozzle, the direction of the guided missile and other components of the rudder. It has intense thermal shock damage to components.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com