Tungsten Copper Infiltration

- Details

- Category: Tungsten Information

- Published on Thursday, 09 March 2017 19:17

Tungsten copper infiltration: Under the action of capillary force, the liquid flows along the particle gap when the metal liquid wetting porous matrix, thus filling the porous W skeleton pores in order to obtain a more dense material. The toughness of tungsten copper alloy can be improved by this method.

Tungsten copper infiltration can be divided into high temperature sintered tungsten skeleton and low temperature sintered partially mixed powder. High temperature sintering of tungsten skeleton after copper infiltration, then sintered in high temperature hydrogen to form the skeleton, sintered tungsten in a vacuum or in a protective atmosphere above the melting point of copper. Under the action of a capillary, molten copper is infiltrated into the tungsten skeleton. Thus, the tungsten copper with relative density of more than 99.2% was developed. The sintered tungsten skeleton is suitable for the preparation of the vacuum tungsten copper with low copper content. This method can obtain higher strength of the skeleton, making the material more resistant to arc burning, the reduction of tungsten powder is more sufficient, and the low melting point impurity can be removed by volatilization and thermal decomposition. At present, this method has been used in the production of large and medium sized high voltage circuit breakers and vacuum switches.

In general, the infiltration of the liquid phase of the copper is only in the tungsten skeleton pore capillary infiltration, densification rate is slow and low. There are some difficult problems in this method, for example, it can not be used to produce Cu content of low and complex shape of tungsten copper element. Due to the harsh requirements of sintering conditions, this method has great limitations in the industrial application.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 09 March 2017 19:10

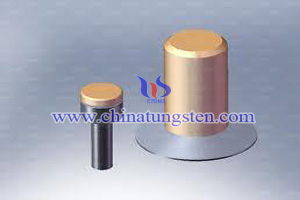

Tungsten copper electrode: Tungsten copper electrode has the advantages of good conductivity, low thermal expansion, high temperature, no softening, high strength, high density and high hardness, composite metal material combined with high purity, high conductivity copper powder and high purity tungsten powder. It can be divided into resistance welding electrode, EDM electrode and high voltage discharge tube electrode.

Resistance welding electrode: Because of the high hardness, high melting point and anti adhesion characteristics of tungsten, it often used to do a certain degree of wear resistance, high temperature resistance projection welding and butt welding electrode. it has good performance of high temperature resistance, arc erosion resistance, high strength, good conductivity and thermal conductivity, easy to cut and transpiration cooling of tungsten copper.

High pressure discharge tube electrode: When the high pressure vacuum discharge tube is working, contact material will increase several thousand degrees Celsius in few seconds, the high corrosion resistance, high toughness and good thermal conductivity of tungsten copper provide the necessary conditions for the stability of the discharge tube.

Spark electrode: Aiming at high temperature mold steel, making super hard alloy electrical corrosion, tungsten copper with high speed electric corrosion, low loss rate, accurate electrode shape and excellent machining performance, different from common electrode, the loss is large and the speed is slow, so it can ensure the accuracy of the machined parts.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Chemical Co-Deposition Method

- Details

- Category: Tungsten Information

- Published on Thursday, 09 March 2017 19:09

Tungsten copper composite oxide powder was prepared by chemical co precipitation method. The nano tungsten copper composite powder was obtained by hydrogen reduction. through sintering and forming obtained tungsten copper.

Tungsten particles of tungsten copper composite powder prepared by chemical co-precipitation method and hydrogen reduction process are polygon, particle size is 30-50nm and it has high sintering activity, thermal conductivity reaches 223.1W/m.K. Compared with traditional products, the conductivity, hardness and bending strength are greatly improved.

The raw materials of it using ammonium tungstate as concentrated HNO₃ and anhydrous cupric nitrate. Firstly, in concentrated HNO₃ when mixing in copper nitrate, then the mixed solution was added into (NH₄O)₂WO₄ solution and the chemical reaction was carried out by an electromagnetic stirrer, after 1 hours remove the mixed solution, the precipitate in the muffle furnace to 250℃ roasting for 2 hours to composite oxide powder. After the composite powder crushed in a mortar, the tungsten copper composite powder is formed by the low temperature reduction of a strong drainage pipe furnace. Tungsten copper composite powder with steel molding after green relative density is 40%-47%. Finally, the ultrafine grained tungsten copper alloy was prepared by 2h sintering at 1150-1250℃ in the hydrogen furnace.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Application

- Details

- Category: Tungsten Information

- Published on Thursday, 09 March 2017 18:52

Tungsten copper application: Tungsten copper has a high range of uses, on the one hand, it is used to manufacture high temperature components, used as electrode and high temperature die, at the same time, it is also used to produce high temperature components, it have been widely used in the field of electric conduction and high temperature. On the other hand, it is also used in aerospace, metallurgy, machinery, sports equipment and other industries.

High performance materials for aerospace applications: The properties of tungsten copper are high density, transpiration cooling, high temperature, high strength and erosion resistance. In the aerospace industry, it is used in the nozzle throat liner of missile and rocket, the components of gas rudder, air rudder, head cover and counterweight.

Tungsten copper electrode: It can be divided into resistance welding electrode, EDM electrode and high voltage discharge tube electrode. It is composite metal material of good conductivity, low thermal expansion, high temperature does not soften, high strength, high density and high hardness which combined with high purity tungsten powder, high purity and high conductivity copper powder.

Vacuum contact material: Arcing due to contact and breaking, the contact material will increase several thousand degrees Celsius in a few seconds. Therefore, the contact material must have very good mechanical properties and thermal shock resistance.

Tungsten copper heat sink: Tungsten copper has the characteristics of low expansion and high thermal conductivity of copper. In order to make the material easier to use, coefficient of thermal expansion and thermal conductivity of tungsten copper can further improvement by adjusting the composition of the material.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Grade

- Details

- Category: Tungsten Information

- Published on Thursday, 09 March 2017 18:44

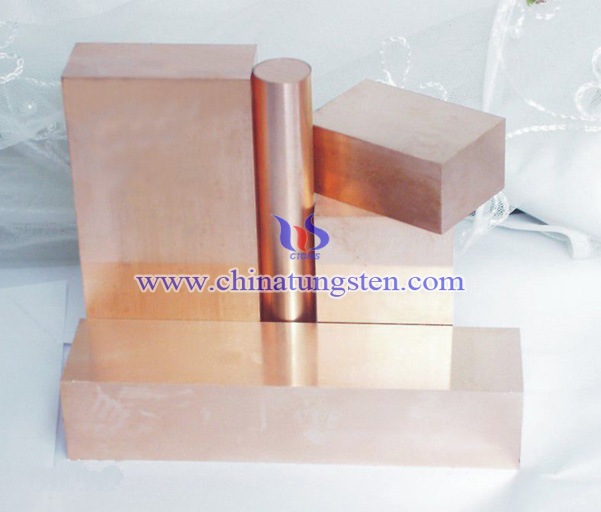

The grades of tungsten copper can be divided into the following four types:

70W30CU: It is formed by the process of static pressure moldings, high temperature sintering and copper infiltrated which combined with the advantages of excellent metal properties of the high pure tungsten powder, high purity copper powder plasticity and high conductivity.

75W25Cu: The tungsten copper electrode has the characteristics of high heat resistance, high thermal conductivity and low expansion, therefore, it is often used in resistance welding, electrical contacts and radiators. As a composite material of tungsten and copper, it has the excellent properties of copper and low thermal expansion.

80W20Cu: It is a tungsten copper grades CuW80 with a 15.58g/cm3 density, with 80% tungsten content and 98HRB hardness. It is widely used in substrates and chips which have the characteristics of silicon carbide, alumina and beryllium oxide and similar thermal expansion.

85W15Cu: This kind of tungsten copper has a great difference in physical properties of copper and tungsten, it can not be produced by powder alloy casting and casting. It is a kind of metal matrix composite made of tungsten and copper.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What is Tungsten Copper

- Details

- Category: Tungsten Information

- Published on Thursday, 09 March 2017 18:09

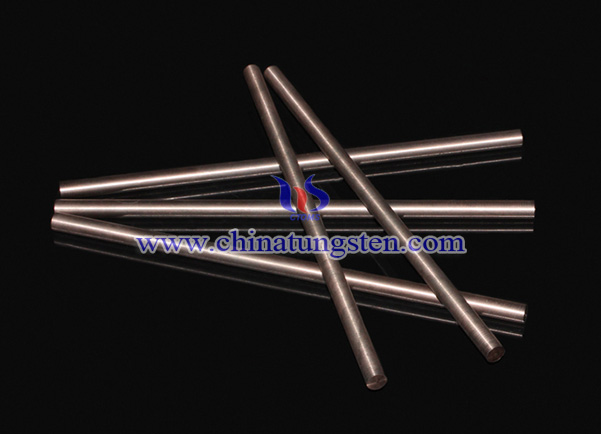

Tungsten copper is composed of tungsten and copper, and its use is relatively wide. It is a kind of alloy made by exquisite soaking sintering process and the content of copper is 10% ~ 50%, it not only has good conductivity and thermal conductivity, but also has high melting point and hardness, resistance to burning and good adhesion. Besides, it has good heat resistance and plasticity, low loss, high precision and high surface finish.

Tungsten copper is widely used in electric welding machine, the welding head of welding machine, welding roller, sealing gas electrode, spark electrode and welding materials. It also used in the electric heating pier coarse block materials, automatic submerged arc welding conductive nozzle and plasma cutting machine nozzle. Sometimes used as a high pressure and super hydraulic switch, breaker contact and guard ring.

At higher temperature, such as 3000 degrees Celsius, the copper in the alloy is liquefied. A large amount of heat in copper is absorbed and reduces the surface temperature of the material. Therefore, it also called metal sweat material.

Because tungsten and copper are not miscible, tungsten copper has high conductivity and thermal conductivity of copper, wear resistance, low expansion and corrosion resistance of tungsten, it also suitable for all kinds of machining. Tungsten copper can be based on user requirements to complete the production and size processing of tungsten copper. Process of powder metallurgy of it is flour mix proportioning and pressing forming.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact for Oil Breaker

- Details

- Category: Tungsten Information

- Published on Thursday, 23 February 2017 16:46

When the oil circuit breaker circuit working, as long as the current in the circuit more than 0.1A, the voltage exceeds a few dozen volts, circuit breaker between the tungsten copper moving contact and the static contact will appear arc, and the current through the arc flow continuously, only when the contact between the separation of a sufficient distance, the arc is only off after the circuit. When tungsten copper contacts are separated from each other, the arc is heated to a temperature higher than that of the insulating oil vaporized and thermally decomposed to form a gas (mainly hydrogen) with strong arc-extinguishing ability.

According to the different insulation of the ground, it can be divided into grounding box multi-oil circuit breaker contacts and charged oil box breaker circuit breaker contacts.

Multi-oil circuit breaker contacts: the arc chamber is installed in a grounded metal box, usually with more oil. Oil is used as both arc-quenching medium and for insulation. With the advantages of simple structure and reliable performance, it can be made into super high pressure grade (such as 362kV), and it can be conveniently used with current transformer, and it is also suitable for outdoor use with little impact on atmospheric condition.

Less oil circuit breaker contacts: the arc chamber is installed in the tank insulation with the earth. Oil is only used as insulation medium and inter-fracture insulation, and not for insulation to the ground, with less oil. Compared with the multi-oil circuit breaker, the small oil circuit breaker is small in size, light in weight and low in oil consumption. It can be assembled into extra-high pressure oil-less circuit breaker and is widely used in the power system.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact for Vacuum Breaker

- Details

- Category: Tungsten Information

- Published on Thursday, 23 February 2017 16:17

Tungsten Copper Contact for Air Breaker

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 February 2017 15:12

Tungsten Copper Contact for SF6 Breaker

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 February 2017 15:02

Tungsten copper contact for high-voltage breaker is kind of oil-free switchgear that uses SF6 gas as arc quenching medium and insulating medium. It has better performance in arc extinguish and insulation than oil circuit breaker and has high requirement of application, management, operation of SF6. So it main used for the voltage level of 110kv. There are two main structure of tungsten copper contact for high-voltage breaker:

Porcelain column structure: It also known as blocks, a plurality of identical unit interrupters and pillar insulators can be used to form the circuit breakers of different voltage levels. The circuit breaker consists of three independent single-phase and one hydraulic, electrical control cabinet. Each phase consists of two pillars of porcelain sets of four interrupters (fracture) in series. In each pillar porcelain top of the unit is equipped with two unit interrupter, 120 ° angle V-shaped arrangement, the two parallel capacitors are arranged horizontally.

Tank structure: Using the advantages of box-type multi-oil circuit breaker, the circuit breaker and the transformer together, compact structure, anti-seismic and anti-fouling ability. It is generally three-phase split-type, single-phase from the base, insulated porcelain casing, current transformers and single-break interrupter with the shell composition. Each phase is equipped with a hydraulic mechanism and a control cabinet which can be operated individually and can be operated in three phases by means of electrical control.

In addition, it has so many advantages compared with other materials:

1. As insulating gas, SF6 has many advantages, is colorless, tasteless, non-toxic, non-flammable inert gas and has performance in cooling arc. Especially cooling effect under high arc temperature;

2. The chemical effect of SF6 gas itself is very stable, and has a very high dielectric strength;

3. Blocking effect: give full play to the effect of air blowing arc, interrupter small size, simple structure, breaking current, arc time is short, breaking capacitor or inductor current without re-ignition, over-voltage;

4. Long electrical life: 50kA full capacity of continuous breaking up to 19 times, the cumulative breaking current up to 4200kA, maintenance cycle is long, suitable for frequent operation;

5. Good sealing performance: SF6 gas has lower water content, arc chamber, resistance and pillar into separate air separation, on-site installation without opening, after installation with automatic connection; installation easy maintenance, and to prevent dirt and moisture Into the circuit breaker inside.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com