Tungsten Copper - SHS

- Details

- Category: Tungsten Information

- Published on Tuesday, 27 December 2016 17:35

Tungsten copper SHS (Self-propagation High-temperature Synthesis) is also called as combustion synthesis, which uses self-heating and self-conducting effects of the high chemical reaction heat between the reactants to synthesize the material. Once the reactant ignited, it will automatically have not yet respond to the spread of the region until the reaction complete. So it is a kind of new method for manufacturing inorganic compound high temperature materials and FGM (Functionally Graded Materials).

The combustion of the reaction or combustion wave propagation speed (0.1 ~ 20.0cm / s, up to 25.0cm / s), combustion wave temperature or reaction temperature (usually in 2100 ~ 3500K above, up to 5000K). SHS is self-propagating to realize the reaction between powders. Compared with the traditional process of preparing materials, the process is reduced, the process is short and the process is simple. After the ignition, the SHS does not need to supply any energy. As the combustion wave through the sample generated by high temperature can remove the volatile impurities, the product purity improved. At the same time, the combustion process has a larger thermal gradient and faster condensation rate, which is possible to form a complex phase, easy to change from some raw materials directly to another product.

Tungsten copper SHS sintering can be in process by 3 ways as follow:

1. Direct combustion synthesis in the air;

2. The pre-heat treated tungsten copper mixed powder is put into a vacuum reactor for synthesis;

3. The synthesis was carried out in a high-pressure reaction vessel filled with reaction gas.

In addition, in order to improve the density of tungsten copper material further, it develop various technology combine SHS with densification, such as SHS densification and SHS welding.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Arc Melting Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 27 December 2016 17:26

Tungsten copper arc melting method uses fusible electrode in a vacuum or inert atmosphere for self-consumption melting, the rapid solidification - aging - solution treatment to obtain fine-grained dense tungsten copper alloy material. It has high density, small density segregation and good corrosion resistance.

Vacuum electric arc furnace consists of furnace, power supply, vacuum system, electronic control system, optical system and water cooling system. The furnace part is composed of furnace shell, electrode, crystallizer and electrode lifting device. In the processing, a low-voltage (20-40 V) high current (several kA) is established between the electrode (negative electrode) and the water-cooled copper crystallizer (positive electrode) to generate an arc discharge, which melts the metal by the heat released from the arc . Electric furnace is generally DC power supply, according to the electrode consumption, it can be divided into Non-consumable electrode arc furnace melting and consumable electrode arc furnace melting.

There are types of heating ways:

1. Direct heating: The arc is generated between the electrode rod and the smelted charge, the charge is directly heated by the arc, and the arc is the sole source of heat for the smelting. It can be specifically divided into:

a. Non-vacuum direct heating three-phase arc melting: More common in the steelmaking process, the electric arc furnace slag inside the furnace can be controlled by the atmosphere to weak oxidizing or even reduction. It has low consumption of alloy in electric arc furnace and easier adjustment, which is suitable for smelting advanced alloy steel;

b. Arc furnace melting: It is mainly used for melting titanium, zirconium, tungsten, molybdenum, tantalum, niobium and other lively and high melting point metals and their alloys, but also for melting heat-resistant steel, stainless steel, tool steel, bearing steel and other alloy steel.

2. Indirect heating: The arc is generated between the two graphite electrodes, and the charge is indirectly heated by the arc. This melting method is mainly used for melting copper and copper alloy.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Fiber Reinforced Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 27 December 2016 17:19

Tungsten copper fiber reinforced method is a kind of process that uses directional tungsten fiber instead of tungsten powder and copper powder overlap each other or cold-rolled short tungsten monofilament fiber and copper powder mixed cold, sintered prepared after the fiber reinforced. It not only has good transverse mechanical properties, but also has excellent conductivity and corrosion resistance. There are some types of ungsten copper fiber reinforced method:

1. Crystallization strengthening: control crystallization conditions, in the solidification after crystallization to obtain good macrostructure and microstructure, thereby improving the performance of tungsten copper material, and it can be specifically divided into:

a. Grain refining: It can provide more grain boundaries for metal structure. Due to the grain boundary hindering the sliding deformation, it can strengthen tungsten copper material on the base of toughness improving;

b. Purification enhancement: In the pouring process, the liquid copper fully purified, to minimize inclusions, can significantly improve the performance of tungsten copper material.

2. Deformation strengthening: After plastic deformation by cold working, dislocation movement of the resistance can increase the strength;

3. Solid solution strengthening: By alloying (adding alloying elements) to form a solid solution, tungsten copper material is strengthened;

4. Phase transformation strengthening: By means of heat treatment to change solid phase, which can be divided into:

a. Precipitation strengthening (dispersion strengthening): In the metal material can form a stable compound of the alloying elements, under certain conditions, so that the formation of the second phase compounds precipitated from the solid solution, dispersed in the organization, thereby effectively improve the strength of the material, usually precipitation of the alloy the compound is carbide phase;

b. Martensite strengthening: After quenching and subsequent tempering of the metal material and heat treatment, the martensite structure can be obtained.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Heat Sink Used for Integrated Circuit

- Details

- Category: Tungsten Information

- Published on Thursday, 22 December 2016 17:49

Tungsten copper heat sink for integrated circuit connects the required transistors, resistors, capacitors and inductors and other components and wiring, made in a small or a few small pieces of semiconductor chips or dielectric substrate, and then packaged in a tube, the circuit has become the desired micro-structure; it combines all components as a whole in structure and promote the development towards miniaturization, low power consumption. Tungsten copper heat sink for integrated circuit has many advantages, such as small volume, light weight, less lead wire and welding point, long life, high reliability, good performance and other advantages, and low cost, easy for mass production. It is widely used not only in industry, civil electronic equipment, such as tape recorders, televisions, computers, but also in military, communications, remote control. With the integrated circuit to the assembly of electronic equipment, the assembly density than the transistor can improve a few times to several thousand times, the equipment can also greatly improve the stability of working.

The main processes of tungsten copper heat sink includes:

1. Infiltration: Manufacture tungsten skeleton with density and strength by pre-sintering, then copper with lower melting point melts and infiltrate into the skeleton to obtain relatively dense tungsten copper material;

2. High-temperature liquid phase sintering: As a large difference between tungsten and copper, it can directly use above the melting point of copper high temperature liquid-phase sintering to promote its densification. In order to improve the density, it should be re-pressure, hot pressing, hot forging and other treatment after liquid sintering;

3. Activated liquid phase sintering: In the W-Cu system by adding a small amount of Co, Ni, Fe, Pd and other activated elements as the alloy in the middle phase can increase the miscibility between tungsten and copper. But the addition of activator has great damage to thermal conductivity and conductivity, and is not suitable for thermal control and electronic control materials.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Heat Sink Used for Electronic Radiator

- Details

- Category: Tungsten Information

- Published on Thursday, 22 December 2016 17:44

Tungsten copper heat sink used for electronic radiator is also called as tungsten copper radiator, which can take heat away and cool down without external power supply. According to different materials, it can be divided into:

Aluminum-extruded heat sink: Aluminum purity is more than 98%, low density, good thermal conductivity and low costs;

Aluminum-casted heat sink: Soft texture, large cooling area, low production costs;

Copper and copper alloy cutting heat sink: In order to meet the constant heat dissipating capacity of CPU, it should use copper and copper alloy, which has higher hardness and better performance in thermal conductivity.

In terms of heat sink materials, each one has different thermal conductivity. According to the thermal conductivity of high to low is silver, copper, aluminum, and steel. However, the silver for the heat sink will be too expensive, the best solution for the use of copper. Although the aluminum is much cheaper, obviously is not as good thermal conductivity of copper and its alloys (only about 50% of copper). Commonly used heat sink material is copper alloy and aluminum alloy, both of them have advantages and disadvantages. Copper has better performance in thermal conductivity, but it has high cost, large in weight, but easy to oxidize. And aluminum is not sufficient in hardness and not good as copper in thermal conductivity.

In addition, tungsten copper heat sink also can be used for CPU can cool down and keep working stability. According to the way of cooling, tungsten copper heat sink for CPU can be divided into three types of air cooling, heat pipe and water cooling.

Air cooling: The most common type of heat sink, including a cooling fan and a heat sink. The principle is the heat generated by the CPU to the heat sink, and then through the fan to take away;

Heat pipe: It is a heat transfer element with extremely high thermal conductivity, which transfers heat by evaporation and condensation of the liquid in a fully enclosed vacuum tube. Most of these fans for the "air-cooled + heat pipe", both air-cooled and heat pipe advantages, with high heat dissipation;

Water cooling: The liquid forced by pump and take away the heat of radiator, compared with air cooling, it is more stable and less dependence to the environment.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Connecting Part

- Details

- Category: Tungsten Information

- Published on Thursday, 22 December 2016 17:31

Tungsten copper connecting part are quite a few in pipeline and it connect the vulnerable part by embedding or welding for improving the performance. In addition, there are some types of tungsten copper connecting parts, such as tungsten copper rivets, tungsten copper bolts, tungsten copper welding bar and so on.

The major locking ways given as follows:

Shape-locking: The formation of a mutual clamping action by the shape of the connecting part or the additional connecting part creates force on the engaging surface which impedes the relative movement between the connecting parts;Friction-locking: Two or more are pressed by the connecting parts, the positive pressure is generated on the joint surface, and when the relative motion between the connecting parts tends to move, frictional force or a frictional torque is generated on the coupling surface to impede the relative movement between the connecting parts;Material-locking: Connect the molecular binding force between materials and connected part, such as welding, cementing.

In addition, it also include:

1. Rivets: A cylindrical short bar having a semicircular stud at one end, penetrating into each of the steel plates or stud holes to be joined, and pressing the extended end into or hammering into a second stud. And it can be divided into four types of semi-round head, high head, buried, semi-buried;

2. Bolts: Usually cylindrical rod, one end of a square or hexagonal head, the other end of the thread, with nuts and washers, steel or steel wood components can be fastened together, which can be divided into two kinds of crude and refined bolts;

3. Welding bar: It melts and fills in the welding joint, which coated by oxidation resistance of welding flux. We can choose the types of welding bar according to the mechanical property, chemical composition and the requirements of welding seam.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

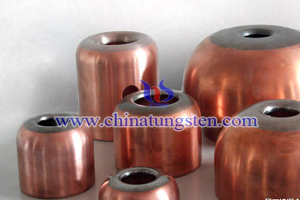

Tungsten Copper Embedded Block

- Details

- Category: Tungsten Information

- Published on Thursday, 22 December 2016 17:26

Tungsten copper embedded block is manufactured by powder metallurgy, which is a kind of typical sweating material. Even if at high temperature (3000℃), the copper evaporation will take away the most part of heat and effectively reduce the surface temperature and keep the strength. In addition, it has perfect conductivity and plasticity, which is beneficial for improving the mechanical properties of the embedded part. There are some applications of tungsten copper embedded block:

1. Electrical materials: In electrical contact and electrical processing, such as electrical contacts, point contacts, electrodes, welding, riveting, electric upsetting, etc., its good conductivity and anti-arc ablation to ensure the accuracy of processing;

2. Instantaneous high temperature materials: Embedded in some vulnerable to high temperature ablation, particle erosion of the site, effectively improve its anti-ablation and thermal shock resistance;

3. Guide materials: Mainly used for a variety of wire rolling, plays an important role in guiding and protecting the workpiece.

Tungsten copper embedded block not only has high melting point (3410℃), low CTE (Coefficient of Thermal Expansion) of W, but also has high conductivity of Cu. So it can control the performance by adjusting the material content. It has been widely used in high pressure, ultra-hydraulic switch and circuit breaker contacts, protection ring, for the electric pier rough anvil material, automatic submerged arc welding nozzle, plasma cutting machine nozzles, welding machine, welding machine welding head, sealing gas electrode and spark electrode, spot welding, touch welding materials.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Spring Contact

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 November 2016 17:49

Tungsten copper spring contact is generally round winding type and the partial deformation will drive entire spring to uniform load distribution.More contact point, high electric current, high thermal stability, electric field distribution, constant contact stress, low wear resistance, low contact resistance, good electrical conductivity, low voltage drop, the use of long pluggable cycle thousands of times. It has been widely used in GCB (gas circuit breaker) / GIS (gas-insulated metal-enclosed combination of electrical appliances), indoor and outdoor high-voltage AC circuit breakers and connectors.

The differences of spring contact and spring are mainly in materials, applications and processes.

Material: Spring contact generally use beryllium copper, tungsten copper, chromium zirconium copper and other copper alloy material, which has special demands to conductivity and wear or corrosion resistance; or spring uses carbon steel, alloy steel and stainless steel and other steel;

Application: Spring contacts are widely used in gas circuit breakers, gas-insulated metal-enclosed contactor, indoor and outdoor high-voltage AC circuit breaker and isolation switch; spring is mainly used to control the movement of parts, ease the impact or vibration, energy storage, widely used in machinery, instrumentation;

Process: Spring contact production process is winding → shaping → spot welding → heat treatment → electroplating; and spring is winding → end face processing (compression spring, tension spring, torsion spring) → heat treatment → process test.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Electrode for Butt Welding

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 November 2016 17:45

Tungsten copper electrode for butt welding uses resistance heat to weld entire workpiece and has high productivity and is suitable for automation. It can be divided into two types of flash butt welding and resistance butt welding.

Resistance butt welding: Two workpiece are always pressed, uses resistance heat to the plastic state of heat, and then quickly apply forging pressure (or not to increase the forging pressure to keep the welding pressure) to complete the welding. It is similar to spot welding, the contact resistance of resistance butt welding depends on the surface condition, temperature and pressure of the contact surface. Oxygen inclusions are easily produced in resistance welded joints. For the welding quality requirements of rare metals, some alloy steel and non-ferrous metals, often using argon, helium and other protective atmosphere to solve;

Flash butt welding: It can be divided into continuous flash butt welding and preheating flash butt welding. Continuous flash butt welding has two main phases: the flash stage and the forging stage. Preheat flash butt welding only adds warm-up phase before the flash phase. Pure copper flash butt welding, it is difficult to form a liquid metal layer at the end and maintain a stable flash process, it is difficult to obtain a good plastic temperature zone. So it needs high flash speed, upsetting speed and forging pressure, tungsten copper material is more suitable.

There are some appilications of tugnsten copper electrode for butt welding:

1. The connection of the workpiece: for example, steel, profiles, wire, steel, rail, boiler steel pipe, oil and gas pipelines and other welding;

2. Butt welding of ring parts: for example, the welding of automobile rims and bicycles, motorcycle wheel rims, butt welding of various links;

3. Assembly welding of components: Simple rolling, forging, stamping or machining parts welded into complex parts to reduce costs. Such as the direction of the car axle housing and rear axle shell of the welding, all kinds of connecting rod, the rod of the welding, welding and other special parts;

4. Dissimilar metal butt welding: can save precious metals, improve product performance. For example, tool of the working part (high-speed steel) and the tail (in the carbon steel) of the welding, internal combustion engine exhaust valve head (heat-resistant steel) and the tail (structural steel) of the welding, aluminum and copper conductive joints welding.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Die Casting Mold

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 November 2016 17:41

Tungsten copper die casting mold is a kind of metal mold to form in the pressure casting process, which molten alloy filling under high temperature, high pressure and cooling solidification molding.

Fixed mold: fixed in the die-casting machine fixed-mounted plate, a sprue with the nozzle or pressure chamber connection;

Movable mold: fixed in the die-casting machine on the mounting plate, and follow the moving mold installation plate for the opening and closing mold moving mold, closed form cavity and casting system, liquid metal filled with high pressure cavity; Separated from the stationary mold, and the casting is pushed out by means of an ejection mechanism;

Cavity and core (inner and outer surface of the sprue and the gate);

Guide parts (guide pin and guide bushing);

Release mechanism: putter (thimble), reset lever, putter fixed plate, push plate, push plate guide column, push plate guide bushing;

Overflow system (overflow tank, exhaust slot), cooling system;

Support components: fixed mold, movable mold plate, pad (for assembly, positioning, installation).

Tungsten copper die casting mold is a big part of molding tool, in order to meet the higher demands, it must applied various surface treatment technology to improve the efficiency, precision and service life. There are many new technology appears constantly, it can be divided into three types:

1. Traditional heat treatment improvement;

2. Surface modification technology, including surface thermal expansion treatment, surface phase transformation strengthening, EDM technology;

3. Coating technology, including electroless plating.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com